High Speed Spindle Helps Mold Maker Stay Ahead

In the competitive arena of moldmaking, shops must produce molds quickly and within tolerance to remain profitable and attract new business. Technological advances in high speed spindles, sophisticated programming methods and high-performance cutting tools allow shops to save time and improve accuracy.

Share

In the competitive arena of moldmaking, shops must produce molds quickly and within tolerance to remain profitable and attract new business. Technological advances in high speed spindles, sophisticated programming methods and high-performance cutting tools allow shops to save time and improve accuracy. However, molded parts are more complicated than ever before because designers are using the latest CAD programs to create parts that would have been unthinkable 5 years ago. So in the quest to improve efficiency, many mold makers are encountering difficulties.

"People say the computer is making things easier," says Randall Ohnemus, president of C&R Molds, Inc. (Ventura, California), "but computers are making things harder for us. Parts have more details these days, because designers can put in all these radii and blends. When parts were drawn by hand, they weren't as complicated, because they were hard to draw."

C&R Molds constantly looks for ways to improve its production. The company employs 40 people and runs three shifts per day to provide full service, from design to production. Backed by ten injection molding presses, the company can take new products from concept to reality—all under one roof. The 12,000-square-foot shop produces molds for a variety of products, from dental tools to water cooler components. Some of the materials the company works with include H13 steel, P20 pre-hardened tool steel and 7075 aluminum. Molds are roughed out on a Haas VF-0 and then finished on C&R's VF-2 with a new high speed spindle.

Since February 2002, C&R has used the vertical machining center equipped with a 30,000-rpm spindle from Haas Automation (Oxnard, California) to perform finish operations on molds. The company has seen a big difference between the new small cutters and what they had before, Mr. Ohnemus says. In addition to yielding better finishes, the spindle also reduces the company's cutting time and allows faster job completion. The same programs that ran on a 15K [15,000-rpm] spindle now run at double their previous speeds and feeds on the 30K spindle. Finish cuts are taken with step-overs of 0.002 inch and depths of 0.002 inch. In addition, the high spindle speed has allowed them to maintain proper chip loads and high surface feed rates.

Proper tooling is another issue the company must continually address in order to improve efficiency. Recent changes in part design, combined with increasing part complexity, have led the company to change its tool selection. It used to be able to cut things with tapered end mills. "But nothing is flat anymore," explains Mr. Ohnemus. "Everything is now blending radii into other surfaces, and that's why we've had to adapt and use ball end mills."

C&R uses ball end mills as small as 0.010-inch diameter to make the finish passes on cavities and mold surfaces. Improvements in cutting tools have helped the company to employ the capabilities of the 30K spindle, and the end mills are making the machine work. The new coatings allow high rpm, so the machine can get through an entire part, whereas before it would have burned up the tool.

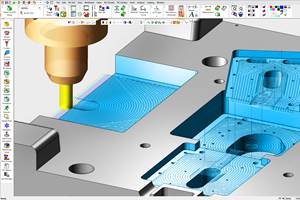

Programming and software have made it possible to machine complicated molds. C&R uses the latest version of MasterCAM to program tool paths—allowing time on certain jobs to decrease from days to hours.

In the past, C&R relied on electrical discharge machining (EDM) for some of the more complex jobs, but now the speed and accuracy of the spindle allow it to machine cavities that were once the domain of EDMs. Since switching to the 30K spindle, the company has eliminated about half of its EDM work because it can machine areas of mold faster. "Previously, we would have burned the thread on this one mold," Mr. Ohnemus explains, "but we were able to machine it with the high speed spindle." Eliminating the need to create electrodes also saves time.

However, electrodes have not been eliminated completely; C&R still uses EDM for certain molds, but this does not mean that the 30K spindle sits idle. Rather, it is put to work machining electrodes, which has boosted electrode production considerably.

The change in vertical machining centers has also reduced the time spent hand finishing and polishing molds. Hand finishing can take days, but the company has reduced the time spent hand finishing by 80 percent with the new machine. By taking light passes at extremely high feed rates with small cutters, the part gets a smooth finish. With some of the small end mills, C&R was able to eliminate much of the hand finishing. Moreover, the CAD-defined geometry and accuracy are maintained when hand finishing is eliminated.

As new technology is making products better, it is also making the production process more complicated. However, the same technology is also helping C&R Molds and companies like it to create molds faster and more accurately than ever before.

Related Content

Lyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More