How One CNC Shop Effectively Machines Glass-Fiber-Filled Plastics

You know how to machine metals, but what about plastic machining? More specifically, glass-fiber-reinforced plastic? This machine shop has it figured out.

Share

K&E Plastics is a Bennington, Vermont, CNC job shop that has been machining plastic components for a range of customers since 1966. It works with both common and engineering thermoplastics as well as advanced, expensive thermoset laminates.

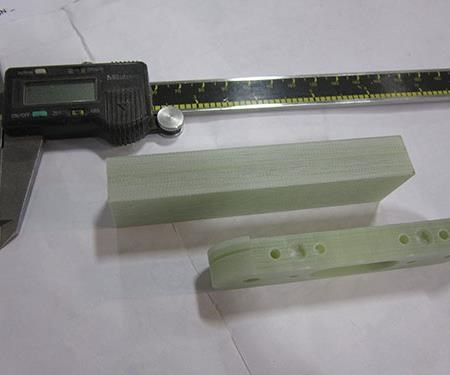

Eric Broderson, K&E’s president, says that glass-fiber-filled plastic materials are the trickiest the shop machines. These include nylon extruded with reinforcing glass fibers and thermoset laminates such as NEMA-rated G7 and G10 that combine layers of glass fabric with resin binder. These materials offer excellent electrical insulating properties, dimensional stability and mechanical strength, and are commonly used for electrical housing components as well as an increasing number of medical and aerospace parts. Although they are attractive from a designer’s perspective, they can be ugly to machine.

There are a number of reasons why this is. The glass filler is highly abrasive, which can cause cutting tools and inserts to wear quickly. Plus, not many cutting tool manufacturers offer tools specifically designed for the non-metallic materials K&E machines (although that’s starting to change). This means some experimentation is typically required to establish effective cutting parameters for new plastic materials. (Speeds and feeds recommended for machining metals with a given cutting tool are typically too high for plastic.) Laminate thermosets are prone to delamination during machining, too, meaning toolpath changes or wholesale design changes might be necessary. Finally, machining these materials creates a significant amount of abrasive dust that must be managed to maintain a clean working environment and keep machines running reliably.

The process K&E has established for glass-fiber-filled plastic machining enables it to overcome these challenges. But as any other short-run operation strives to do, it has also found ways to become more effective at minimizing non-value-adding activities, which I learned about during a recent visit to K&E’s new facility near the foothills of Vermont’s Green Mountains.

Only Plastic

Mr. Broderson’s father, Peter, started K&E in New Jersey after leaving his position as a salesman for a vulcanized fiber components manufacturer. In 1986, he moved the company to Vermont. Eric took over running the business 20 years ago with the goal of pursuing non-electrical plastic applications, primarily in the aerospace and medical industries, to diversify the company and realize higher margins. Although K&E originally had only manual machines, the 24-person shop now has all CNC production equipment in the new 30,000 square-foot facility it moved into in May. The vast majority of these CNC machines are Haas models, including VMCs, gantry routers and turning centers.

The Haas VMCs and routers have a grease-pack spindle design rather than oil-lube, which Mr. Broderson says is important for plastic machining because the lubricant remains sealed within the spindle and can’t contaminate the plastic workpieces. Similarly, nearly all K&E’s thermoset laminate jobs are performed dry or with cold-air guns, although synthetic coolants are used for some thermoplastics. (The shop currently uses Koolrite 2510 from JTM Products, which contains no sulfur or chlorine.) Petroleum-based coolants can’t be used because they often degrade plastic workpieces.

K&E runs only plastic jobs across its CNCs. That’s because many of the components the shop machines are used for electrical insulation applications; running only plastic eliminates the chance that a stray chip from a previous metal-machining job would contaminate the plastic workpiece. This is also why plastic vise jaws are commonly used instead of aluminum or steel jaws.

Most jobs start from plastic sheet, tube or rod material, but some work is performed on customer-supplied molded components. Typical batch sizes range from 35 to 70 pieces, so, like any other job shop, K&E takes strides to minimize setup and change-over time. For instance, all VMCs have been purchased new or retrofitted with a Renishaw touch-tigger probing package. This enables machinists to quickly locate vises or fixtures during setups, reducing set up time from a couple of hours to just 20 minutes in many cases. Similarly, the shop stores its most commonly used tools in known positions in each machine’s toolchanger carousel to minimize the frequency of tool change-outs. And when possible, it runs similar parts or part families together to minimize the number of times one type of workholding device must be swapped out for another.

Some machines are also fitted with vacuum workholding chucks to speed change-overs and enable tools to access five sides of a part. Vacuum plays a key role in dust removal, too. Unlike metal machining that creates manageable chips that can be conveyed out of a machine, plastic machining creates tiny chips and a good deal of dust. Therefore, all machines are connected to a central dust collection system to minimize dust build-up on machine components and maintain a clean facility.

K&E previously used a traditional bag-type dust collection system. That system wasn’t able to keep up as more machines were added, however, and machine operators spent too much time manually vacuuming the machines. Therefore, K&E recently installed a cartridge filter system from United Air Specialists with a modular design that enables the shop to add plenums as dust-control demands increase. Plus, the cartridges typically last two years before replacement is needed compared with bag clean-out every few months. The system also returns clean, warm air into the facility when the weather is cold, which lowers heating costs.

The dust generated during plastic machining causes K&E to take machine maintenance seriously, too. The shop runs 10-hour shifts Monday through Thursday, and operators spend the last hour of each Thursday cleaning the machines. In addition, spindle and way covers are removed every six months to eliminate any dust build-up, and machine air filters are replaced on a regular basis.

Cutter Considerations

In general, the best cutters for glass-fiber-filled plastic materials have positive rake angles and very sharp cutting edges. K&E has traditionally used solid carbide cutters, but it is transitioning to indexable carbide insert tooling, because, ultimately, indexable-insert tooling is less expensive and requires less inventory space, Mr. Broderson notes. Plus, he says it enables higher positive rake angles.

The shop maintains a close relationship with its tooling distributor, Abrasives and Tools of New Hampshire (ATNH), to stay abreast of new indexable insert cutters that might be well-suited for its plastic materials. Its primary contact at ATNH is Nate Despins, sales engineer. One of his recent projects with K&E was to identify a new 6-inch face mill to replace an existing model that could achieve a feed rate of just 9 ipm for a glass-fiber-filled nylon component. Mr. Despins suggested a Kennametal Dodeka 45-degree face mill using KC410m-grade inserts, which have a titanium diboride (TiB2) coating. This coating offers the wear resistance needed for the material’s abrasive glass filler but is relatively thin so as not to dull the insert cutting edges (which is what a thick coating effectively does). These inserts have the sharpness that’s needed to cleanly cut glass-filled nylon while not burning the resin. This new tool increased cutting performance to 30 ipm/500 rpm for roughing and 20 ipm/500 rpm for finishing.

For another project, Mr. Despins was asked to suggest a more productive end mill for machining a G-10 thermoset laminate component (G10 uses an epoxy resin unlike G7, which uses a silicon resin). When using an end mill with conventional carbide inserts, the fastest speed and feed rate that could be achieved were 1,200 rpm and 19 ipm, respectively. Plus, only one part could be completed for each insert cutting edge. Mr. Despins suggested a Mill 1-10 shoulder mill from Kennametal that has a highly positive rake angle and KD1410-grade, polycrystalline diamond (PCD) inserts. The KD1410 inserts have a PCD tip brazed onto one side. Although these inserts are twice the cost of the conventional carbide inserts, and the PCD tip is on just one side of each insert, they achieved five times the life of the previous inserts while enabling faster machining. During roughing, this new tool ran at 2,000 rpm and 40 ipm with a 0.08-inch depth cut. For finishing, it ran at 4,000 rpm and 90 ipm at a 0.02-inch depth of cut.

Heat is the big issue when machining any plastic. Material burning is possible when tools are run too fast. Plus, without effective chip evacuation, machined material can re-weld back to the workpiece. Tool flute geometry plays a key role in getting chips out and away from the workpiece, as do cold-air jets. However, thermoset laminates such as G7 and G10 are also prone to delamination depending on the bond strength of the resin and how the parts are machined.

Ball end mills are typically used for surface profiling of G7 and G10, and the tool stepover used depends on the material and surface finish requirements. When a very smooth finish is needed, stepovers are generally in the 0.0005- to 0.001-inch range compared to 0.005 inch for applications in which surface finish isn’t that critical. That said, because G7 has lower resin bond strength, custom, precision-ground tool may be necessary to prevent delamination from occurring.

Drilling and tapping can also be problematic. It’s best to enter perpendicular to the laminations; entering parallel to them can cause delamination. But when threaded holes are required parallel to the laminations, peck drilling should be performed, followed by thread milling. A thread mill is much less likely to split the material compared to a conventional tap, largely because there’s less tool pressure. Another alternative is to drill a hole and install a threaded metal insert.

On the Horizon

K&E plans to continue to experiment with new cutting tool options and will soon replace the few non-Haas VMCs it infrequently uses. It is also looking to add to its quality control capabilities. The shop currently has a video measurement machine (which is especially good for parts with many holes), but will soon purchase a Metris CMM. K&E is also considering upgrading its machine tools’ touch-trigger probing software to enable in-process part inspection. Mr. Broderson says the work for medical and aerospace customers is driving the shop in this direction, because these jobs tend to be more complex than electrical components, making inspection more challenging. Plus, performing measurements with the part still on the machine means there’s less handling as well as reduced machine downtime because operators don’t have to wait extended periods of time while a part is sent to the quality department for measurement.

Sidebar: Software Simplifies ISO Certification

K&E has used the E2 Shop System from Shoptech Software for 15 years, benefiting from easier and more accurate job quoting, improved job data collection, real-time reporting capabilities, and so on. However, it also leveraged this software platform to streamline its ISO certification process. The E2 Accelerated Quality Certification (AQC) program includes software and documentation as well as on-site consulting services for quality system training. Pre-assessment audits are conducted by a Shoptech quality management lead auditor to determine a shop’s readiness for an actual certification audit. During K&E’s pre-assessment audit in 2012, the Shoptech auditor found no major infractions and offered only a few recommended suggestions. Soon after, the shop received its ISO 9001:2008 certification on its first attempt. Because it is making a bigger push into the medical market, K&E’s next goal is to become certified to the ISO 13485 medical-device standard.

Related Content

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More