The In-House Initiative

OEMs experiencing outsourcing issues might consider this manufacturer’s approach to establishing an appropriate level of in-house machining capabilities.

Share

E.F. Bavis is a leading manufacturer of pneumatic and mechanical drive-thru systems for banks, pharmacies, restaurants and other businesses. Located in Maineville, Ohio, this company has worked over the years to become vertically integrated, and now has manufacturing capabilities including sheet metal fabrication, welding, plastics molding, vacuum forming and wire-harness assembly.

Machining was one of the last manufacturing processes the company brought in-house, although it still uses outside vendors for some of that work. Mike Brown, vice president of manufacturing, says that’s because it makes sense to send some jobs to trusted suppliers, particularly for parts that are complex or have large batch sizes. However, when volumes are small and the work matches the level of machining capability at the company’s facility, it is often able to produce the parts more affordably in-house.

But beyond cost savings, Mr. Brown points to other advantages of having a captive machine shop. For example, the shop helps the company maintain manageable inventory levels. There’s no need to purchase a large number of parts at an attractive low cost when small batches can be produced in-house at a comparable price. Plus, the company doesn’t end up stuck with a lot of obsolete inventory if drive-thru designs change or custom pieces are required. Instead, for example, it can keep an inventory of material blanks on hand and machine new parts as needed. Lastly, machining capability offers insurance in case a supplier shuts its doors or demand for a part becomes so low that it’s no longer cost-effective to use an outside vendor.

Adding Machining

Edward Bavis established the business in 1959 to produce cabinets, countertops and commercial furnishings. Mr. Brown joined the company in 1984. Over time, the company turned its focus to drive-thru systems. Today, E.F. Bavis is a leading provider of remote drive-thru systems and related equipment, including bullet-proof windows, lane lights and transaction drawers. Plus, it is the only company to offer solar-powered drive-thru equipment for select applications.

When Mr. Brown took over as vice president of manufacturing, he began adding to its manufacturing capabilities (beginning with fabrication and wire-harness assembly departments) to better support efforts to expand the product line. In 2002, supplier issues with one plastic part prompted him to acquire the company’s first CNC machine, a Haas TM-1 toolroom mill, and bring that job in-house.

The part is made of 0.75-inch-thick polypropylene measuring 4 inches wide and 12 to 20 inches long, depending on the application. Mr. Brown originally turned to a woodworking shop that used a router to create multiple parts from large sheet material. Due to the router’s limited rigidity, the parts this shop created were inaccurate and had poor surface finishes (appearance is critical because the components are visible to drive-thru users). Mr. Brown next tried a local machine shop. Although this shop could deliver the tolerances, the production cost was exceptionally high due in part to the low batch size as well as the shop’s conventional mentality that a vise should be used for workpiece fixturing.

Ultimately, Mr. Brown developed a process to produce these parts on the new mill using custom fixturing. He created one fixture for drilling and countersinking operations and another for milling the perimeters of the parts. In just six months, this single job paid for the $19,000 CNC mill. Soon after, the company purchased a second TM-1. Installing the drilling/countersinking fixture on one machine and the fixture for perimeter milling on the other enabled one operator to tend both machines. The company eventually purchased a CNC lathe as well as its third TM-1, this one with a toolchanger, for both mold machining and production work.

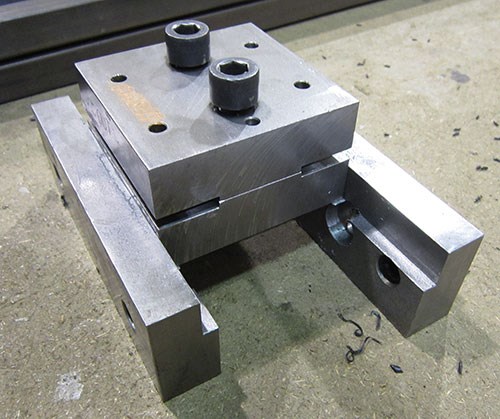

What you will rarely see is a vise installed on any of these mills. Instead, Mr. Brown creates fixtures for virtually all in-house production work. To speed job change-over and simplify setups, he installed a hardened dowel pin receiver in the center of each mill’s table onto which fixtures are positioned. During setup, an operator needs only call up a G54 workpiece coordinate system code (defining the center of the dowel pin) followed by a G52 local coordinate system code to create a temporary work offset specific to the fixture that’s installed. This way, operators don’t have to indicate newly installed fixtures, and NC programs can be copied and added to each mill so parts can be run on any available machine.

While some fixtures are relatively simple, Mr. Brown has created other workholding devices that are more complex. He says these are worth the investment, however, when volumes are relatively high or it’s known that the part will be required long into the future. Examples of these workholding devices include a vacuum chuck (which uses the motor from a vacuum cleaner) and a rotary table with an air motor that accommodates long, anodized rectangular tubes, indexing them 180 degrees to enable drilling operations on either side.

The only production part in which a vise is used is a steel end cap for window frames. Still, the vise secures a job-specific fixture rather than the parts themselves. The fixture is held in custom jaws and accommodates two end caps. Hardened set screws help secure the caps during machining. After machining the perimeter profile and backside rabbet, the operator removes the fixture from the vise, flips it and re-installs it so each cap’s radius can be milled. The end caps are then welded to the window frame from the back so no grinding is needed. Two completed parts are produced in three minutes, and the cost to produce each is $3 versus an outside shop that quoted $5 per piece.

The Right Amount of Machining

Mr. Brown admits the company’s machining capabilities are modest, and no one on staff is a machining expert. But in recognizing this, the company is still able to leverage its machining and related manufacturing resources and design new products around its in-house processes. That said, the true cost of in-house manufacturing must always be determined and considered because there sometimes will be instances in which it makes more sense to use an outside vendor.

Related Content

Additive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreFANUC Details Robotic Vision, ROBODRILLS and More at IMTS 2024

FANUC’s IMTS 2024 booth includes real-time demonstrations that show the abilities of its equipment, including robots, controllers and machine tools.

Read MoreDN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read MoreMazak VMC Provides Versatile Machining of Complex Parts

The VC-Ez 20X vertical machining center features a 25-hp 12,000-rpm CAT-40 spindle with a 30-tool-magazine automatic tool changer.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=970;quality=90)