Share

“In the bottom of these gear teeth, they have a very small radius,” explains Mike Stephens, TTI’s engineering prototype shops senior manager. “There isn’t any room for error. We have to be 100% sure of our process because everything has to be repeatable. By making quality gears, we’re ensuring that their smooth interaction with each other is reducing noise and chatter that might occur.” Photos provided by Mastercam.

Specialty gears — especially those with complex shapes or tolerances such as spur, helical, bevel, miter, spiral, and pinion gears — have historically been components that Techtronic Industries (TTI) farmed out of its Anderson, South Carolina, campus. Mike Stephens, TTI’s engineering prototype shops senior manager, and his team had attempted to apply cost-effective and timely solutions to producing the gears, often by combining mill, lathe, and wire EDM technology, but it was not working.

Stephens’ team produces around 1,000 parts monthly, whether that be completely new prototypes or reiterations of and improvements to existing parts.

Keeping Pace and Quality

To maintain this pace without sacrificing part quality, Stephens prefers to keep the vast majority of machining in-house. Almost every tool that TTI manufactures has at least one gear, and bringing that production in-house would be a boon. To see what could be done, Stephens reached out to Barefoot CNC, the reseller of his Mastercam CAD/CAM software. He knew he wanted to find a solution that worked with the software he has been using for over 20 years.

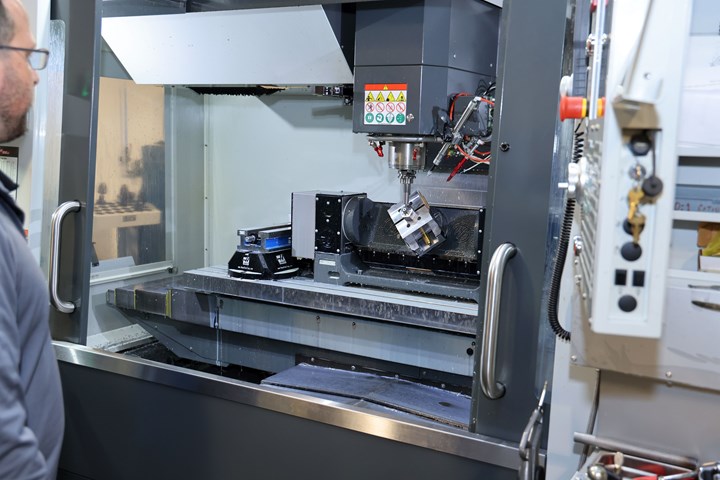

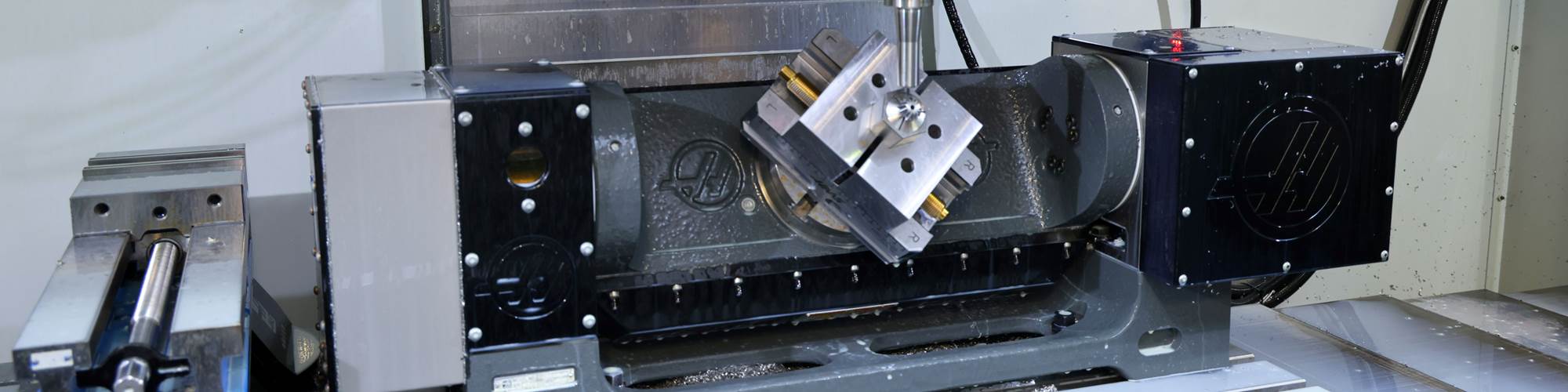

Stephens purchased a Mastercam Multiaxis Solution license and a Haas VF-3 Super Speed unit with TR-160 trunnion to give his shop multiaxis capabilities.

With Barefoot’s guidance, Stephens purchased a Mastercam Multiaxis license and a Haas VF-3 Super Speed unit with a TR-160 trunnion to give his shop 3+2-axis capabilities. Barefoot has supported TTI with training courses, certification courses, expert insight and product support for over 20 years.

“As our machining requirements have become increasingly complex over the years, Barefoot and our software have been right there with us,” Stephens says. Barefoot owner Jimmy Wakeford, applications engineer Jamie Boyd, and their team helped develop a postprocessor for Stephens’ multiaxis machine and helped troubleshoot TTI in its gear production.

The postprocessor Barefoot helped to develop served as the link between Stephens’ CAD/CAM software and the machine tool. The post takes the intermediary code from Mastercam and translates it into the language required by the control that drives the machine. Each machine tool uses a specific control type, which requires G-codes unique to each machine manufacturer. Stephen’s specific post was created based on his machine tool’s axis configuration, control type, and control options.

Almost every tool TTI manufactures has at least one gear, so bringing that production in-house was a major goal of Stephens’.

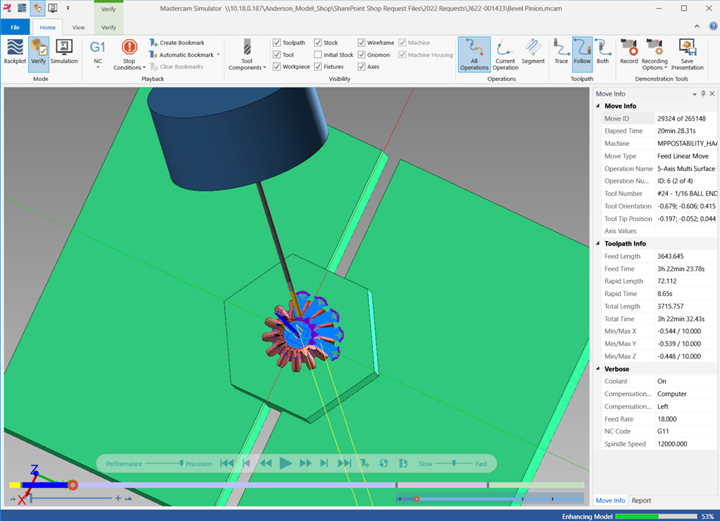

When a gear model first enters the shop, it comes as a solid model, Parasolid CAD file in NX, or Solidworks file. Stephens or one of his team members opens the file in Mastercam and re-orients it, if necessary.

Then, the programmer selects the part profile and/or geometry and starts applying tool paths. Before the cutting tool ever touches the material, everything is set: geometries, cutters, cut patterns, depths of cuts, axis controls, and entry/exit methods. Stephens says Mastercam helps him create shapes that would not be possible otherwise.

Before applying his CAD/CAM software to specialty gears, Stephens relied on rotary heads and indexers that require human interaction. He can unload that responsibility to his computer, but he still likes being able to adjust parameters as he sees fit. Stephens explained that he and his team don’t simply feed a piece of paper into the machine and sit back while it spits out a part. His software is highly customizable, meaning he can fine-tune every aspect of toolpathing and tolerances to get exactly what he wants.

Getting in Shape

The first step of machining a gear is lathe cutting the gear blank to the model’s established geometry. This is also the phase of production in which a boss or other shape is cut into the back of the part for fixturing at later stages. Then, the team focuses on the general shape of the gear. They often first utilize Rotary Advanced five-axis toolpathing, which excels with cylindrical or radially symmetrical shapes, to cut these gears, some of which are the size of a dime.

“In the bottom of these gear teeth, they have a very small radius,” Stephens explains. “There isn’t any room for error. We have to be 100% sure of our process because everything has to be repeatable. By making quality gears, we’re ensuring that their smooth interaction with each other is reducing noise and chatter that might occur.”

Stephens’ software comes equipped with full verification and simulation programs. He can run these diagnostic checks the first time he programs a part and then trust his machines to never crash or ruin a part for every iteration after.

Dynamic Work Offsets and Tool Center Point Control technology are often the workhorses of the chosen toolpaths, cutting away the majority of the material at high speeds. When a machine runs a Dynamic toolpath, its feeds, speeds and angles are adjusted as soon as the stock-aware toolpath notices any warping, air cuts, or unoptimized chip size. It not only keeps machining safe, but it also prolongs tool life by keeping the entire flute length engaged with the material.

“We’ve noticed markedly longer tool life, and we have smoother toolpaths now. I feel so confident that I leave the machine running every night unwatched,” Stephens says.

His software comes equipped with full verification and simulation programs, so he can run these diagnostic checks the first time he programs a part and then trust his machines to never crash or ruin a part for every iteration after. Not only is he saving money in material and tooling, but Stephens says he is also saving time by running machines lights-out.

By bringing gear production in-house, TTI has turned a four- to ten-week lead time into a one- to two-week lead time. “Using multiaxis machining and our personalized machine post with machine simulation has completely changed our mindset,” Stephens says, “Now, we don’t approach troublesome parts as, ‘No way.’ Now it’s, ‘No problem.’”

Related Content

WFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreIndustry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreRead Next

What Parts Make Sense for Multitasking?

One of the striking things about Mazak’s new knowledge center on multitasking is how few of the part examples included within it are round.

Read MoreThe Five Levels of Multitasking

When it comes to multitasking equipment, one size by no means fits all. Mazak helps shops sort it out in their Multitasking Knowledge Center here on MMS Online.

Read MoreMultitasking's "Big" Advantage

As demonstrated at this Cincinnati-area shop, machines that both mill and turn shine brightest when workpieces are massive.

Read More

.jpg;maxWidth=400;quality=70)