Makino Inc.

7680 Innovation Way

Mason, OH 45040 US

513-573-7200

sales@makino.com

makino.com

IS THIS YOUR COMPANY?

Video Gallery

Makino EDM Tech Tip: Energizer Indexing on the Makino UX series Wire EDM

In this Makino EDM Tech Tip, see how quick and easy it is to index the upper and lower energizers (also called power feed ...

Makino EDM Tech Tip: Resin Tank Change on the Makino UX series Wire EDM

In this Makino EDM Tech Tip, Makino Application Engineer explains how to exchange the resin tank on a Makino UX series Wire ...

Makino EDM Tech Tip: Filter Change on the Makino UX series Wire EDM

In this week's Makino EDM tech tip we show how easy it is to purge and change the water dielectric filters on a Makino UX series ...

Guide Maintenance on the Makino UX series Wire EDM

In this quick Tech Tip, Makino Application Engineer explain how to clean and maintain the upper and lower guides on a UX Series ...

As Seen On Modern Machine Shop

Makino Inc. Supplies the Following Products

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Automatic Storage/Retrieval Systems

- Graphite Milling

- Horizontal, Five-Axis

- Horizontal, Up to Four-Axis

- Knee & Column Milling, Non-ATC

- Leasing & Financing

- Machine Monitoring

- Machining Cells & FMS

- Maintenance & Repair

- Material Removal Automation

- Nano & Micro Machining

- Pallet Changers/Shuttles & Programmable Transfer Devices

- Pallet Systems

- Ram Type (Die-Sinking) CNC EDM

- Retrofitting, Rebuilding, Remanufacturing Services

- Robots, Industrial

- Small Hole EDM

- Tool, Cutter & Drill Point

- Training

- Universal (ID/OD)

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

- Wire Type EDM

Trade Names Offered by Makino Inc.

- Wire Wizard

- PS series VMC

- MCC-VG HMC

- 1 Series HMC

- EDBV3-Series EDM Hole Drilling

- EDAF series sinker EDM

- Professional 5 control

- Belly Wizard

- V-Series VMC

- EDFH-Series EDM Hole Drilling

- D-Series VMC

- MCC & MCD Series HMC

- MAG Series HMC

- EDAF-FH-Series EDM Hold Drilling

- V-Series Graphic Machining Centers

- Track Pallet Magazine

- F series VMC

- UPV series wire edm

- EDAC-Series Sinker EDM

- ADVANTiGE Technology

- iQ300 VMC

- A Series HMC

- Super Geometric Intelligence (SGI)

- Online Training

- Super Spark

- Pro5 PC

- J Series HMC

- MMC-R

- GF Series VMC

- EDNC Series Ram EDM

- G-Series HMC

- U Series Wire EDM

- MCD-Series HMC

- MCF-Series HMC

- T-Series HMC

- MMC2

- N-Series HMC

- MCi Series HMC

- HQSF

- HEAT

Editorial, News, and Products

-

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

-

Refining Shopfloor Processes for Mission-Critical Parts

Pacon Mfg, Inc. has not rested on its laurels as the 2020 Top Shop Honoree for Shopfloor Practices and Performance. In the years since, it has refined its processes to continue excelling in a volatile market.

-

Sustainability Project Cuts Costs for Growing Manufacturer

A custom coolant and chip management system has helped Youngers and Sons lower its supply costs, improve its recycling margins and maintain a clean shop floor.

-

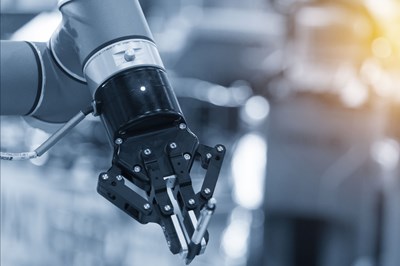

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

Integration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

-

Why Go Five-Axis: Machine Types and Benefits

Even as the benefits of five-axis machining stack up year by year, the barrier for entry crumbles.

-

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

-

Voice Activated Machine Interface Comes to Machine Tools

Voice-enabled virtual assistants are coming to machine tools. Now available on Makino wire EDMs, the ATHENA interface promises to help manufacturers better utilize their equipment, aid less skilled workers and operate more machines with fewer people.

-

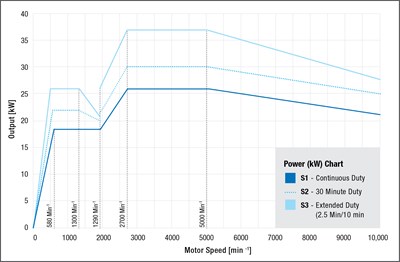

Back to the Charts for Productive Milling

Roughing operations can push a CNC spindle to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits.

-

Machining 101: What is Electrical Discharge Machining?

Electrical discharge machining, or EDM, is a non-contact form of machining that projects sparks from an electrode or wire to vaporize material of any hardness.

-

Makino and Additive Industries Sign Process Integration LOI

Makino and Additive Industries have signed a letter of intent to develop integrated process chains for industrialized metal additive manufacturing and postprocessing.

-

Voice Control of Machine Tools has Arrived

Voice interface technology has come of age and is now found on a wide variety of products such as phones, tablets, PCs, TV remotes and many other devices. Why not on machine tools as well?

-

Standardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

-

Hard Milling Replaces Hand Grinding in Finishing Die Components

A focus on repeatability, geometric capabilities and speed led this manufacturer of fine-blanking machines and components to embrace hard milling as its go-to finishing process, eliminating hand grinding.

-

New Business Plan Enables Shop to Increase Ventilator Part Production

KrisDee and Associates was able to increase production of a ventilator manifold from 90 parts per week to 780 parts per week thanks to changes the company started making months earlier.

-

What Capabilities Do You Need for Medical Machining?

Machining orthopedic implants, instruments and tooling places special demands on machining centers. Here’s what to look for to achieve the highest quality and most efficient machining processes.

-

How AM Is Advancing into Cutting Tools: Photos from EMO

The design freedom of additive manufacturing delivers increased performance to cutting tools. At the world’s leading exposition for machine tools, I saw various examples of this.

-

How to Double the Speed of Wire EDM

Makino’s new H.E.A.T. Extreme technology makes wire EDM 2 to 3 times faster without increasing wire consumption. With a thicker wire that delivers more energy, this development is a game changer in the economics of EDM.

-

5 Impressions of EMO 2019, from Automated to Autonomous Manufacturing

The robot show? Not quite that. But automation and the expectation of processes that can run unattended if needed are clearly core to manufacturing now.

-

Hitting the Zone with Five-Axis Machining

By investing in five-axis machining technology, Advance CNC Machining has done more than just add new capabilities to its roster. It has found a way to achieve something that most of us strive for: a way to work “in the zone.”

-

Attacking Unplanned Machine Tool Downtime with Predictive Maintenance

A new predictive maintenance application on Makino machining centers identifies issues before they turn into production problems. It also helps optimize machining processes and increase equipment utilization.

-

Makino's U6 H.E.A.T. Extreme Improves Machining Speed and Performance

Makino’s U6 H.E.A.T. Extreme wire EDM is designed to increase machining rates while maintaining traditional wire consumption.

-

Center of Excellence Is New Twist on Old Manufacturing Department Structure

The new Spirit AeroSystems facility for five-axis machining allows a small team to oversee a significant amount of machining capability. Is this the way of the future as machining systems become more automated?

-

Wire EDM Improves Operational Economy

Eastec 2019: Makino’s U6 H.E.A.T. (High Efficiency Advanced Technology) Extreme wire EDM features Athena voice command control capability and 0.016" diameter wire technology.

-

Three Expectations for Robotic Automation

Shops take some modern robot capabilities as given, but a recent trade show in Japan demonstrated ways those capabilities continue to improve.

-

AMB 2018 Highlights E-Mobility and Lightweight Construction

More than 91,000 attendees gathered at the AMB trade show in Germany to visit 1,553 exhibitors and talk about the impact of e-mobility, Industry 4.0 and other relevant topics.

-

How Voice Recognition Will Transform Machine Tool Technology

For now, new voice recognition technology is a way to more efficiently run a machine tool. Soon, it will provide access to a whole world of shop floor information.

-

Five-Axis CNC Machining with an Angled Rotary Table

The D200Z CNC five-axis VMC uses an angled rotary table designed to improve rigidity and clearance for high-speed machining.

-

“Athena, Transform Manufacturing”: Voice-Activated Machining Technology in Multiple Demos

Makino and iT SpeeX demonstrate a new digital assistant for machining. Athena brings voice control to CNC and voice-actuated access to information the machinist needs.

-

Five-Axis HMC Accommodates Complex Geometries, Decreases Setups

Makino’s five-axis A500Z features a fully-integrated “Z-type” fifth axis to accommodate complex part geometry challenges in fewer workholding setups and machining operations.

-

Will Voice Recognition Enable a Transformational HMI for Machine Tools? (See Video)

A new digital assistant for machining brings voice control to various CNC types and voice-actuated access to machine-tool-related information. Given its promise to free shopfloor personnel to work more effectively, one machine tool builder sees it as a potentially game-changing development.

-

Makino's UP6 Wire EDM – Designed for Ultra Precision Machining

Makino will introduce the new UP6 Heat Wire EDM machine at IMTS that is designed for Ultra Precision machining.

-

VMC Enhances High-Speed Five-Axis Machining for Die/Mold Tooling and Medical Parts

The Makino D200Z five-axis vertical machining center combines the quickness of machine movements and accuracies with the latest software developments for high-precision, high-speed motion control.

-

VMC Aggressively Attacks Five-Side and Full Five-Axis Machining

Makino announces its latest full five-axis machine solution, the DA300 vertical machining center, providing the ideal blend of speed, precision and flexibility for complex part applications.

-

Five-Axis VMC Delivers Maximum Precision and High-Quality Finishes

Makino introduces the next-generation vertical machining center for true five-axis continuous processing, the V90S.

-

Wire EDM Improves Positional Accuracy

IMTS 2018: Makino’s UP6 Heat Wire EDM is designed for precision stamping and fine blanking applications.

-

Machining Technology Spotted at Amerimold 2018

Amerimold presents a range of mold production equipment, strategies and best practices. Here is some of the mold machining technology displayed at this year’s event, ranging from automation to CAD/CAM.

-

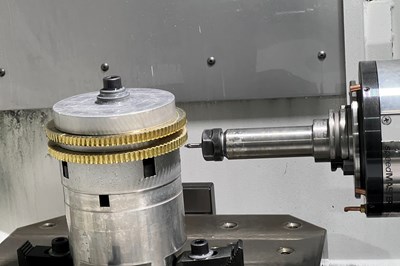

Updated HMCs Support Unattended Operation

IMTS 2018: Makino’s latest a51nx and a61nx HMCs feature increased spindle torque and improved tool monitoring.

-

Makino Enhances the a51nx and a61nx HMC Platforms

Building on the performance and reliability of its top-performing horizontal machine platforms, Makino offers the high-capability a51nx and a61nx horizontal machining centers.

-

June 2018 Product Spotlight: EDM

This month’s Modern Equipment Review Spotlight focuses on electrical discharge machines (EDMs) tailored to a variety of industries.

-

Using Data to Do Better in Manufacturing

Although the Smart Manufacturing Experience 2018 event in Boston may not have provided a simple, clear definition of “smart manufacturing,” it did provide a broad experience of what smart manufacturing can be like.

-

Four Questions a Shop Considering HMCs Should Ask

Compared to vertical machining centers, horizontal machining centers offer the potential for improved spindle uptime, cycle times and throughput. Although they come with a higher price tag, their higher productivity can be significant to shops of all sizes, as Valley Tool has experienced.

-

EDMs’ Rise-and-Fall Work Tanks Improve Access, Visibility

Makino’s Edge2 and Edge3 EDMs are built to provide accurate and reliable performance for standard die/mold components and contract manufacturing.

-

Applications Enable Remote Monitoring, Control of EDMs

With the release of HyperConnect, Makino offers a suite of Industrial Internet of Things (IIoT) applications for EDMs designed to enhance user experience and efficiency as well as reduce machine downtime.

-

Updated Five-Axis HMC Efficiently Machines Aluminum

Makino’s updated MAG3-EX five-axis horizontal machining center is designed for processing aluminum aerospace parts.

-

Measuring Components Help Job Shop Triple Capacity

Magnolia Tooling's older, less-accurate machines required time-consuming manual setup procedures. Purchasing new machines from Makino and accessories from Blum-Novotest streamlined setup and optimized production.

-

Growing with the Times (and Customer Demands)

Faced with the choice to innovate and invest or be left behind, Turbine Technologies chose to invest in EDM machines from Makino.

-

EDM Machine Probing Possibilities

Probing options for electrical discharge machining equipment range from simple to sophisticated. Here are options for wire, sinker and hole-drilling EDM.

-

Massive Machining Center Features Fast Rapids

Makino’s a120nx is designed to machine oversized structural components for industrial equipment, diesel engines and semiconductor manufacturing.

-

VMC Outfitted for Various Automation Options

Makino offers the L2 vertical machining center designed for high-volume, small-part manufacturing.

-

What a Machining Center Really Costs: Total Lifecycle ROI

A white paper explains why it’s important to look at the entire lifecycle of a machine to determine its true costs and benefits.

-

What It Takes to Connect

Development of the IIoT brings with it new requirements to control, monitor and analyze these massive amounts of data, and convert them into actionable business intelligence in real time.

-

Automation Increases Production, Employee Retention

Employee fatigue at SEW Eurodrive was limiting productivity when production demands increased. Automation from Makino helped to increase machine utilization as well as worker satisfaction.

-

Five-Axis VMC Processes Complex Parts in Aluminum, Die-Cast, Titanium

Makino’s DA300 full five-axis vertical machining center is said to provide the speed, precision and flexibility necessary for complex part applications.

-

Integrated Waterjet Expands Laser Cutting Potential

Designed for small, intricate features like turbine blade cooling holes, technology that fuses water and light virtually eliminates the traditional drawbacks of laser cutting without compromising the benefits.

-

Machine Control Emphasizes Conformity to Operator Workflow

Makino introduces the Professional 6 (Pro6) control designed to move operators fluidly through machine setup and protect them with enhanced safety.

-

June 2016 Product Spotlight Slideshow: EDM

This month’s Modern Equipment Review Spotlight focuses on electric discharge machines, or EDMs.

-

Shop Favors Different Flavor of Five-Axis Technology

Campbell Engineering benefits from a new twist on the tombstone workholding concept, which enables one of its HMCs to perform 3+2 machining to reduce scrap while supporting the higher-volume needs of its medical customers.

-

Ingenuity Meets Automation. Lunch Meets Learn.

Sponsored Content – IMTS 2016 Technology eNewsletter

-

Meet the Humans Behind Makino Adaptive Automation

Sponsored Content - IMTS 2016 Technology eNewsletter

-

Standardized Parameters Make Unattended Machining Reliable

Standardized parameters for specific material and cutting tool combinations help this hard milling specialist manage a highly varied workload with minimal labor.

-

VMC Helps Shop Find Tight-Tolerance Niche

YDC Precision Machine's VMCs needed more capacity and capability, so it invested in a Makino PS95 vertical machining center that cut cycle times in half.

-

VMC Makes Big R&D Strides on Micro Applications

Waters Corp. needed to develop extremely tight-tolerance prototypes quickly, so the company upgraded to a Makino iQ300 VMC to produce complex, low-volume part concepts for R&D.

-

Wire EDM Provides Higher Rigidity, Thermal Stability

Makino will spotlight its U3 wire EDM, which merges all machine components into a single base structure for improved mechanical rigidity and thermal stability.

-

Micromachining Center Promotes Component Temperature Control

Makino’s iQ300 precision micromachining center offers improved component temperature control and 0.005-micron scale feedback for sub-micron accuracy.

-

Automated Five-Axis Cell Streamlines Production

Abipa Canada made its move into automation leveraging a fixture plate distribution system and an HMC, minimizing setup time and lowering part production costs.

-

March 2015 Product Spotlight Slideshow: Machining Centers

Click through this slideshow for HMCs, VMCs, multitasking centers and more.

-

Five-Axis Machining Center for Efficient Job Shop Production

Makino’s T1 five-axis horizontal machining center is designed for industrial component manufacturing and aerospace job shop applications where machining both soft and hard metals is required.

-

Getting in Touch with Optimal EDM Results

Makino’s Hyper i control for wire EDM uses touchscreen navigation in its user interface, which helps a basic user to match the productivity and capability of an experienced operator.

-

Automated Fixture Plate Distribution System Reduces Setup Times

Makino’s MMC-R automation system for robotic plate distribution is said to promote efficiency in high-mix, low-volume production.

-

Five-Axis HMC Equipped with Work-Pallet Magazine

Makino’s a51nx-5XU five-axis horizontal machining center incorporates a fifth-axis table and work pallet magazine, and is intended to serve as an alternative to single-pallet-load vertical machining centers for machining of small parts.

-

The Decision Not to Automate Fully

Robotic automation for this machining line was feasible, but the company chose to run it 24/7 with a staff hired just for this job.

-

HMCs Help Bow Manufacturer Improve Technology, Productivity

By incorporating a Makino a51nx horizontal machining center into its production process, Mathews Inc. was able to increase its efficiency and keep bow production in-house.

-

A Production Line Takes Shape

Although Pointe Precision built its reputation on low-volume, high-complexity aerospace and medical parts, its expansive high-volume production line may be its biggest success to date. Sound decision-making and attention to details at every step are the keys to this success.

-

Adopting a 24/7 Mindset

This shop considered a number of factors before establishing an effective process to run an HMC cell around the clock for applications in aerospace, oilfield and other industries.

-

Improvement Is Not Optional

No matter how busy this shop gets, it continues to pull teams of employees out of production so they can focus on solving problems to make incremental process changes. The advances add up. Today, this is a very different shop than it once was.

-

Flexible Manufacturing System Shortens Lead Times

A Makino MMC cell and a81 machines provide a flexible production environment that helped Roush Industries take on a wider variety of work with shortened lead times.

-

Addressing the Skills Gap

According to Roush Industries Operations Manager Mel Koslowski, one way to address the skills gap is to expose kids to programs in high school that will pique their interest in manufacturing careers.

-

The Costs and Benefits of Horizontal Machining

The shift from vertical to horizontal machining was even more expensive than this shop anticipated. It was also more valuable. Most of the shop’s machining centers are HMCs now—here’s why.

-

HMC Expands Work Zone

Makino's a81nx horizontal machining center increases the size of the work zone from other NX series machines to accommodate large parts requiring diverse tool types and sizes.

-

5-Axis VMC Provides Speed, Precision for Complex Mold Machining

Makino will showcase its D300 five-axis vertical machining center, designed specifically for complex, 3D contouring in die and mold applications.

-

March 2014 Product Spotlight: Machining Centers

This slideshow features the machining centers we cover in the Modern Equipment Review Spotlight section in our March issue.

-

Five-Axis HMC for Efficient Large Workpiece Production

Makino’s T1 five-axis horizontal machining center enables high-efficiency machining for a range of large workpiece applications such as those required by the industrial, energy and aerospace industries.

-

Wire EDMs Provide Versatility

Makino offers its U3 and U6 general-purpose wire EDMs designed for ease of operation and versatility.

-

HMC Provides Quality Needed for Medical Manufacturing

Big River Engineering and Manufacturing purchased a high-precision Makino a51 HMC to meet FDA regulations and gain customers in the medical device manufacturing industry.

-

Five-Axis Machining Center Sustains Accuracy

Makino’s D800Z five-axis vertical machining center is designed for high-performance job-shop, precision parts machining, die and mold, and aerospace applications.

-

Events Highlight New EDMs, Micromachining Technology

Back-to-back events drew hundreds to Makino’s Auburn Hills, Michigan tech center last week for technical presentations, machine demos, networking and more.

-

Five-Axis HMC Designed for Small Aerospace Parts

Makino’s a61nx-5E five-axis horizontal machining center is well-suited for the production of complex aluminum aerospace parts, including small components with 3D contours.

-

Tool Management Drives Process Standardization

From incoming order to final delivery, this aerospace component manufacturer strives to eliminate process variables. Airtight control of cutting tool inventory is critical to that effort.

-

“Right-Sized” Machine for Structural Aerospace Parts

This five-axis machine offers a compact footprint and atypical automated pallet changing system for small, yet challenging aerospace structural components.

-

High Speed Leads to Lights-Out

This mold maker has become more competitive by establishing a high speed machining process that is predictable enough to confidently run lights-out.

-

Event Highlights Automotive Production Solutions

Makino recently highlighted various examples of its latest automotive production technology and detailed strategies for responding to the pressure faced by manufacturers in that industry.

-

Event Highlights Solutions for Aero Structural Parts

The thin walls and deep pockets common to structural aerospace parts make machining challenging. A recent event at Makino’s U.S. headquarters highlighted solutions for effectively machining such tricky aluminum and titanium components.

-

Video: Five-Axis Machine’s Atypical Pallet Changing System

Makino’s a61nx-5E five-axis machine features an atypical pallet changing system that brings effective ergonomics to five-axis machining.

-

Precision Micromachining Center Features Temperature Control

Makino’s iQ300 precision micromachining center uses 0.005 micron scale feedback for increased sub-micron accuracy.

-

Shop-Wide Automation Approach Enables 24/7 Machining

Using a flexible manufacturing system (FMS) and a 24/7 hour machining approach has enabled Micro-Mechanics to make production changes on the fly and virtually eliminate downtime

-

Fast-Hole Drill EDM for Aerospace Blade and Vane Machining

The EDBV3 fast-hole drill EDM from Makino is designed for discharge machining of cooling air holes and shaped diffuser holes in aerospace blade and vane segments.

-

What JIMTOF Had to Show Us

We present here some of the interesting and visually appealing snapshots from JIMTOF 2012.

-

Five-Axis HMCs for Aluminum Machining of Structural Aerospace Parts

A-series five-axis HMCs from Makino are designed for high-speed, high-efficiency aluminum machining.

-

Creative Demos Showcase Capabilities of Both Micro-Scale Machine Tools and Machines for Massive Parts

Makino’s Booth S-8700 is full of various machine tools performing live cutting demonstrations in applications including a medium-to-high-volume automated production system for automotive parts, a robot-tended small machining center for orthopedic part production, and a machining center with grinding capability performing aircraft blade and vane machining.

-

Fully Committed to Zero Stock Machining

Milling critical mold surfaces to final size (or even a “tenth” undersize) literally leaves no margin for error. This takes absolute confidence in every aspect of the machining process, as well as absolute confidence that the results are worthwhile.

-

Sinker EDM Technology Speeds Deep-Rib Roughing

Makino’s SuperSpark IV sinker EDM technology is designed to reduce roughing times in deep-rib applications.

-

Building on the Right Foundations

One of the largest vertical turning and milling centers in the country will be installed in this Cincinnati-area job shop. Although installing the foundation for this huge machine was a massive undertaking, the company is building on other “foundations” as well.

-

Cell’s Benefits Derive From Sum of Its Parts

This shop’s experience with implementing a cell consisting of four robot-fed HMCS demonstrates that success depends on more than automation alone.

-

A Big-Picture View of Micromachining

Matrix Tooling makes injection molds for components that have features you cannot see.

-

What Makes for an Effective, Production-Oriented VMC?

Extended VMC cycle times due to modest spindle performance and slow non-cutting functions can increase costs for high-volume applications. However, new VMC offerings can minimize cycle times while maximizing competitiveness for production work.

-

Precision Micromachining Center for High Speed Machining

Makino says its iQ300 precision micromachining center incorporates the latest advances in machine and spindle design, thermal control and precision.

-

How Effective is MQL for Drilling Titanium/Aluminum Stacks?

Titanium expert Mark Larson describes how coolant properties affect the cut. MQL might work, but water-based coolant is typically best in titanium.

-

Real-Time Data Management Software Maximizes Productivity

Makino’s Machine Productivity Maximizer (MPmax) is a process monitoring and data management software that connects multiple machines on a single network to a centralized computer, enabling manufacturers to retrieve, store and analyze high volumes of machine data in real-time.

-

Five-Axis HMC Machines Titanium

Makino’s T2 five-axis HMC with Advantige technology is designed for mid-sized titanium aerospace part production.

-

Make Maximum Use of the Magazine

This shop streamlined its selection of cutting tools to machine a number of parts on a pallet system. Cutting down on cutters delivered other benefits as well.

-

EDM, Metrology System Pairing Opens New Doors

Seeking a solution for producing and measuring smaller, more intricate parts, this shop combined a ram EDM unit and optical 3D metrology system. Each provided significant benefits on its own, but the pairing of the two technologies enabled the company to achieve new levels of precision and productivity.

-

Disaster in Japan: A Spirit of Generosity Will Prevail

Despite last week’s horrendous disaster, Japan will carry on.

-

Tool-Related Considerations for More Efficient Machining of Titanium

The expert in our Titanium Machining Zone offers advice related to coolants and coatings.

-

How Do You Equip a Startup Micromachining Shop?

A response to a reader’s question includes a checklist for launching a small shop focused on micromachining.

-

Machining Complex Parts on a Five-Axis VMC

Makino’s F5-5XR VMC combines high-performance hard milling with multi-axis capability for increased accuracy, speed, flexibility and productivity.

-

Precision Metrology Supplier Relies on HMC Accuracy

Global metrology supplier Quality Vision International produces critical measurement equipment components in-house to control quality and accuracy. HMCs from Makino enabled the company to not only achieve the precision required for components of one multi-sensor system, but also significantly reduce cycle times.

-

Controlling Burr Formation within Small Intersecting Holes

A reader struggles with burrs between intersecting holes 1 mm and less in diameter. MMS Online’s micromachining expert offers advice.

-

Hard Milling Reduces Lead Time, Manual Labor

Investing in a hard milling machine from Makino has enabled this fineblanking manufacturer to reduce lead time by 55 percent, reduce manual labor and improve part quality.

-

Taking on Titanium

The challenge for the aerospace machine shop is to produce titanium parts productively and profitably. The challenge for the machine tool builder is to help such shops meet this challenge.

-

VMC for Die/Mold and Medical Markets

Makino’s F series VMCs are designed to provide stiffness and rigidity for chatter-free cutting; agility for high-speed/hard-milling; and accuracy for tight tolerance blends and matches typical of complex, 3D contoured geometry associated with die/mold and medical production.

-

Automated Fixture Plate Distribution System.

Makino’s MMC-R automation system is designed for robotic fixture plate distribution in HMCs and VMCs.

-

VMC For Complex Geometries

Designed to machine complex geometries, Makino’s F3 VMC is designed for rigidity and micron-range positioning accuracies and repeatability.

-

Dial Down or Dial Up?

Vibration analysis may be the machining center’s missing piece. If you haven’t performed this analysis on your high speed machine, you probably don’t know what the machine can do.

-

When to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

-

A Significant Cell

Manual loading of heavy housings was this manufacturer’s prime bottleneck. It had limited experience with automated cells, but decided to install a big one. A look at the manufacturer’s $13 million cell reveals an intriguing layout and blend of technologies.

-

The Hidden Cost Of EDM Wire Consumption

Excessive wire consumption on a wire electrical discharge machine is costly. Technology that allows slower unspooling speeds without compromising results appears to be the answer.

-

Shifting Gears To Integral Drive Adds Productivity

Machines with geared-head spindles are typically employed for machining titanium and other tough materials that require high torque. However, replacing such models with integral-drive HMCs from Makino has enabled this contract manufacturer to significantly improve productivity on time-sensitive aerospace jobs.

-

What’s Ahead For The North American Auto Industry

Here are highlights from a presentation by an auto-industry observer at Makino’s recent technology expo.

-

Does Small-Hole Drilling Demand a Fast Spindle?

A reader with a 10,000-rpm drill press can drill a 0.019-inch hole in stainless, as long as all the contributors to runout are controlled.

-

How Do You Get The Cutting Parameters Right For Small End Mills?

A reader recently asked about speed, feed rate and depth of cut when using small tools in steel.

-

Using Small End Mills In Steel Without Breaking

A reader wants to mill with small tools on a straightforward VMC used for full-sized work. MMS Online’s micromachining expert offers advice.

-

Five-Axis Aluminum Machining Centers

Makino’s next generation of MAG series five-axis machinery, the A7, provides increased accuracy and reduced cycle times for large complex aluminum monolithic parts for aerospace structural applications. The A7 is designed with extended X-, Y- and Z-axis travels of 276" × 99" × 40" (7,000 mm × 2,500 mm × 1,000 mm) to accommodate parts as large as 276" × 79" × 28" (7,000 mm × 2,000 mm × 700 mm) that weigh as much as 11,024 lbs (5,000 kg).

-

Coolant And Center-Drilling Considerations For Machining Small Holes

Through-spindle coolant is good if you can get it, but the spot drilling might not be necessary. Try a pilot hole instead?

-

HMC Efficiently Machines Titanium

Makino’s T4 five-axis HMC combines lean manufacturing methods with increased metal removal rates for aerospace applications. It is specifically designed for the production of large titanium and titanium alloy aerospace parts including edge frames, pylons and bulkheads.

-

How Do You Machine a 30:1 Hole in Stainless Without the Drill Wandering?

An expert in micromachining says one answer is to check various aspects of the drilling process. Another answer is not to use a drill at all.

-

Too Small To Touch

Hummingbird takes on machining work that is too small for most shops to handle. In fact, Hummingbird tries not to handle it either. To accurately machine the tiniest parts, this shop relies on processes that are as hands-off as possible.

-

Threading A Horizontal Wire EDM

A wire EDM machine designed for micromachining uses negative air pressure to thread the fine wire.

-

Keeping Things In Focus

Machine-mounted video cameras are part of a system that help a shop owner get more work done while spending less time in the shop. He can monitor and control what’s happening on his machines remotely. He’s also developed strategies for reacting to events such as unexpected tool wear or sudden tool breakage without returning to the shop to fix the problem.

-

Video: Helical Interpolation Vs. Drilling

A machining center able to maintain precise control at high feed rates makes it practical to machine holes through helical milling as an alternative to drilling.

-

Hard Milling By The Numbers

Here are some speeds, feed rates and depths of cut for a productive hard milling process.

-

Where Is Your Wiggle Room?

"Lights out" doesn’t require an intense commitment. This job shop achieves flexible unattended machining when it needs it using palletized HMCs.

-

Custom Solution Enables Quick Production Of Knee Component

This maker of implantable medical components can now machine the entire outside surface of a knee component in one setup.

-

Where New Machines And Methods Overshadow The Old

Eclipse Mold makes a good case for high-end machining centers as the basis for effectively machining to zero.

-

The Hard Milling Imperative

Hard milling allows mold components to be machined in the hardened state, thus skipping several expensive and time-consuming processes such as electrical discharge machining and hand polishing.

-

Measuring Tool Length For Micron Accuracy

Measuring the length of the cutting tool in the spindle is critical.

-

Multitasking Ram EDM

Multitasking capability is coming to EDM. This ram EDM unit can switch from ram to wire EDM to produce holes as small as 0.03 mm in diameter.

-

Unplug-And-Play Hydraulic Workholding

An OEM and contract shop have found value in an unconventional, untethered hydraulic workholding method that uses mechanical energy transfer to charge a fixture's sealed hydraulic circuit. Free and easy HMC pallet movement is the result.

-

Who's Afraid To Cut To Zero?

Most U.S. mold shops still leave extra stock on the cores and cavities of the molds they machine. This practice is unnecessary and wasteful, say proponents of advanced machining technology.

-

Getting To Submicron Accuracy

Machie tools designed for submicron accuracy and subminiature workpieces are following design strategies that depart from conventional practice. The Hyper2J from Makino is described as a case in point.

-

Wire EDM Goes Horizontal

Wire EDM (electrical discharge machining) has been configured with the wire in a vertical orientation for decades, so the appearance of a wire machine that orients the wire horizontally is truly a novel development.

-

Cutting The Learning Curve

A grinding shop in western Pennsylvania uses self-teaching CNCs to boost productivity.

-

Six Advantages Of Horizontal High Speed Machining

Large monolithic aircraft parts may be machined more productively one at a time instead of three at once.

-

HMC s Yield Big Gains For Mold Base Shop

This shop was pleasantly surprised to discover that, besides making chips faster, its new horizontal machining centers also enabled them to eliminate a time-consuming, secondary operation.

-

A Boring System For Non-Round Holes

Machining an out-of-round bore is easy if you're not particular about the location or magnitude of the roundness error. But accurately machining a hole that has a precisely defined non-round profile is a capability that would seem to be well beyond what a standard boring bar can accomplish.

-

New Fixture Multiplies Productivity Of Horizontal Machining Center

The setup for batch processing of each stem version and time expended in load/unload for the second operation created a production bottleneck that became more critical as market demand for the part took off.

-

On The Path To Automation

Implementing an integrated tooling system proved to be this mold shop's first step toward automated operation of its electrical discharge machines and graphite mills. Today, the shop's robotic cells can run around the clock in an unattended mode.

-

Better HSM For Big Parts

'High speed machining' is accepted and commonplace in many shops. HSM is so widely used, in fact, that its acceptance is beginning to affect the design of machine tools.

-

The Efficiency Effect

Using machining centers that might otherwise mill electrodes, this Minnesota mold shop does its cutting directly in steel. The streamlined process has exceeded expectations and yielded a striking increase in sales.

-

Processing The Process

The high speed horizontal machining centers in this manufacturing cell represent a very efficient process for machining cast iron transmission cases. How the crew runs and maintains this cell represents a very efficient process for making this cell ever more productive and cost effective.

-

In Latest Version Of

Look-ahead is a common CNC capability today. The term describes the control's ability to read ahead some number of blocks in the program, to anticipate sudden changes in speed or direction and react accordingly. Different CNCs look ahead different numbers of blocks. But are more blocks better?

-

The Case For Additive Technology In EDM

Producing fine finishes on EDMed surfaces has long been a goal, especially for mold and die shops that operate ram-type electrical discharge machines. Lately, there has been renewed interest in using additives in the dielectric oil to achieve ultra fine finishes with graphite electrodes without excessive burn times.

-

The Practically Dedicated Flexible Cell

Machining centers make sense for this high volume process, even though the machines have continuously produced just one part for years.

-

Interpolating Curves

The ability to import complex curves into CNCs promises to let shops finally get beyond old limitations imposed by contouring with linear interpolation. Faster and smoother cutting will be the result.

-

It's Within Your Grasp -- It Will Extend Your Reach

Though high speed machining means different things to different people, all of the diverse applications of this process involve performing operations fast enough to break into a new realm of possibilities.

-

Cycle Time Is In The Cut Now

High volume machining centers have become so efficient outside the cut that the widest margin for productivity gain is within it.