Machining Technology Spotted at Amerimold 2018

Amerimold presents a range of mold production equipment, strategies and best practices. Here is some of the mold machining technology displayed at this year’s event, ranging from automation to CAD/CAM.

Share

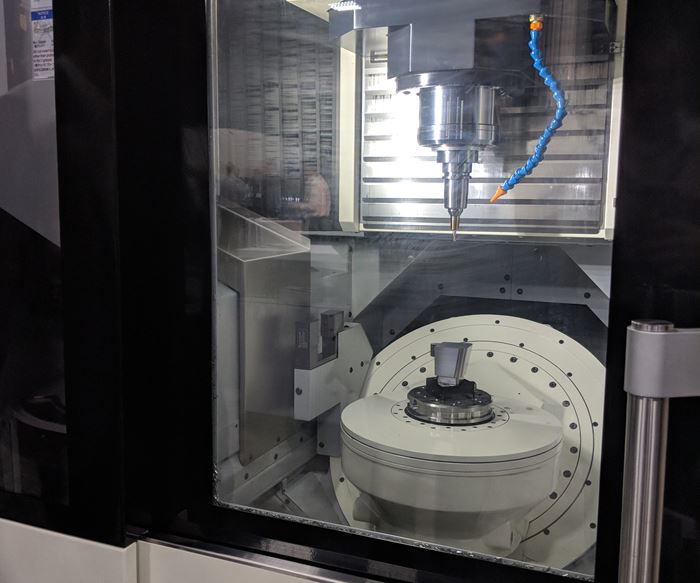

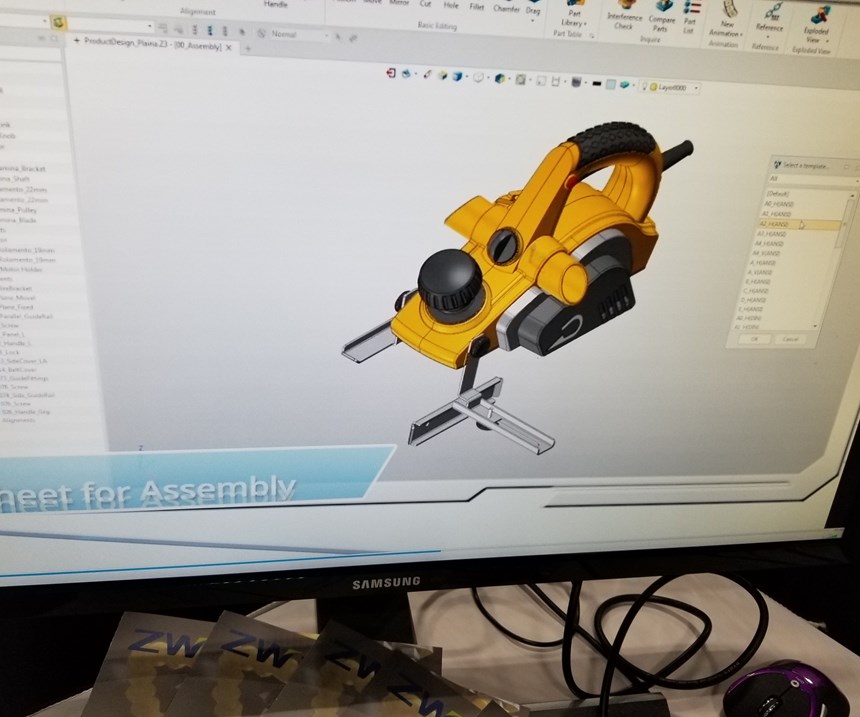

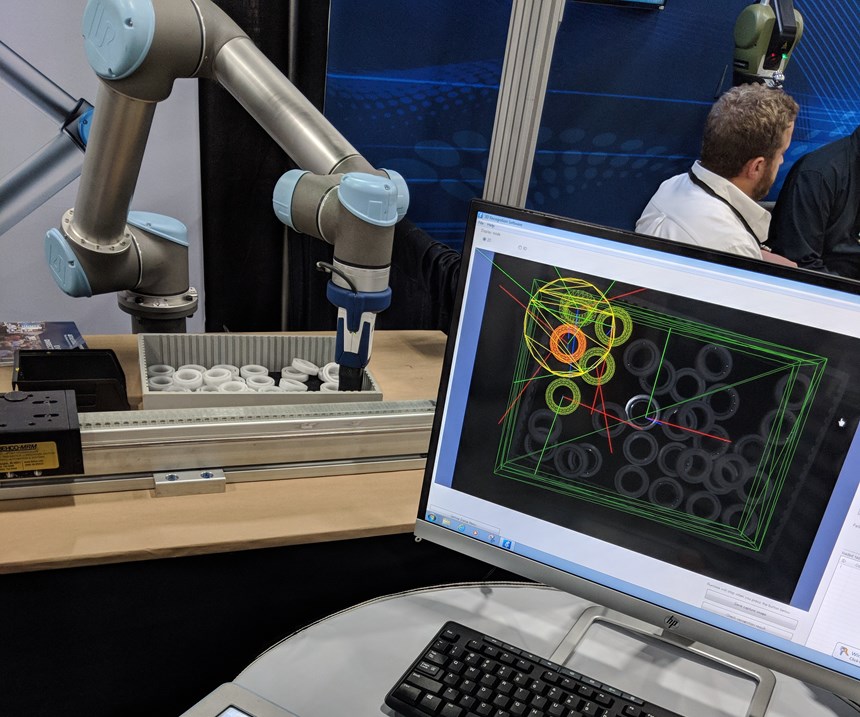

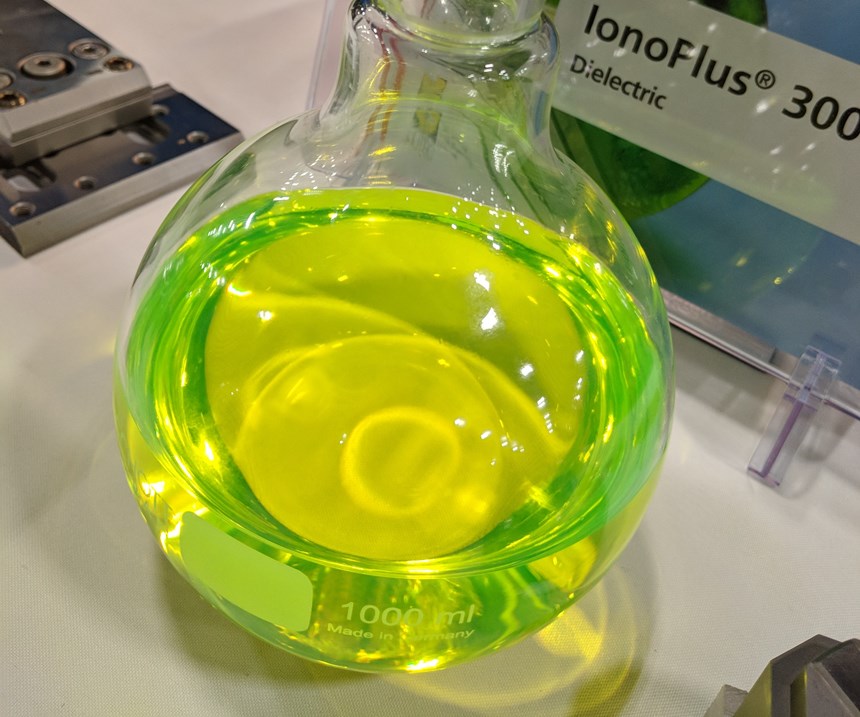

Amerimold 2018 featured a range of technology from nearly all aspects of the injection mold manufacturing process, with some exhibitors showcasing these capabilities with live demonstrations.

Mold machining products on display included CAD/CAM software for mold design and machine tool programming, five-axis machine tools designed to improve accuracy, tool presetters that can save save time by determining tool offsets offline, cutting tools to enable higher metal removal rates, collaborative robots to automate production tasks, workholding designed to provide machine tools with unobstructed access to workpieces, and EDM equipment that can deliver quality surface finishes. Scroll through the photos and captions above for highlights from the show.

Related Content

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.