High Speed Leads to Lights-Out

This mold maker has become more competitive by establishing a high speed machining process that is predictable enough to confidently run lights-out.

Share

By developing a reliable process for unattended, high speed machining of mold cores and cavities, Quality Tooling has boosted its competitiveness to the point where it is starting to win work that previously was outsourced overseas. Although it took the Corydon, Kentucky tooling manufacturer a little while to gain the confidence to run lights-out, its systematic approach has resulted in a high speed machining process that performs effectively, regardless of whether an operator is in front of a machine. This is particularly important when you consider that intricate jobs might require as much as 30 to 60 hours of machining time.

The family-owned business is led by brothers Mike and Brian Alvey. Its lead CAM programmers are Mike’s son, Stephen, and long-time employee Jeramy Lamb. Brian admits that the company was a bit late to the game when it comes to high speed machining of tool steel mold blocks. This is partly because it pays for equipment up front and in full to remain debt-free, a policy initiated by his father, Jim, who started Quality Tooling in his garage in 1968. Over time, however, the company eventually assembled all the complementary elements needed for effective high speed machining, including the appropriate machines, cutting tools and software. Now, it can produce finished mold surfaces that require little or no hand polishing or spotting, which has greatly reduced manufacturing costs and delivery times. High speed machining of blocks has also decreased the need for sinker EDM operations (and related electrode machining). In addition, job quotes are more accurate because unexpected machining mistakes that might require block welding, reworking or possibly even scrapping have been greatly minimized.

Ultimately, Quality Tooling’s predictable high speed machining process paved the way to added capacity and lights-out production. The latter enables the company to run machines unattended through nights, weekends and holidays to wring the most production out of every day.

Building a High Speed Process

Quality Tooling is a 27-person company that originally designed and manufactured only plastic injection molds, but has since diversified its capabilities to produce rubber, die-cast and blow molds as well. It also performs a good deal of mold repair work, which represents approximately 20 percent of its business.

Establishing a lights-out mold machining process wasn’t the goal when Quality Tooling first considered high speed machining. Instead, it viewed high speed machining as a necessary step to improve efficiency by machining contoured mold surfaces to net shape with minimal bench work. This is accomplished by taking a number of light cuts with close stepovers to minimize the size of the material cusps left behind. Feed rates and spindle speeds must be higher than conventional machining operations so the cutting tool can achieve an effective, consistent chip load. Higher feed rates make it possible to complete a greater number of passes across the workpiece to reduce cycle times.

Although Quality Tooling’s existing CNC machines were well-suited for traditional mold machining work, they weren’t geared toward high speed machining. Therefore, the company’s first step was identifying a machine that could deliver higher spindle speeds and feed rates along with the requisite accuracy for complex 3D mold surfaces. After performing its own research and considering opinions from others in the industry, it chose a 30-hp, 20,000-rpm V55 from Makino in 2000. This VMC with an HSK-63a spindle interface has a FANUC 16i-m CNC running Makino’s Super Geometric Intelligence (SGI) servo-control software. SGI uses part program block look-ahead and fast processing capability to take advantage of the machine’s quick acceleration and deceleration rates and fine-position-resolution feedback. It anticipates the servo lag or following error for upcoming toolpath motions and moves the machine to those points prior to receiving the actual feedback from the servo drive. This compensates for servo error to help achieve accurate, smooth tool paths.

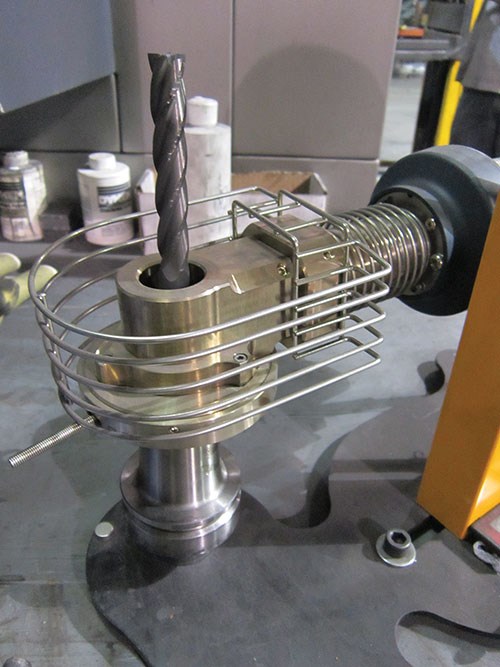

Another piece of the high speed machining puzzle was the adoption of balanced shrink-fit toolholders from OSG. Shrink-fit toolholders offer minimal runout, so there’s effectively no off-center rotation of the cutting tool that would cause a higher chip load on one flute and shorter tool life. The shrink-fit tool/toolholder interface is also extremely rigid, enabling cutters to reach deep into pockets and other difficult-to-access areas. This reduces the number of sinker EDM operations that would otherwise be needed to create those surfaces. Quality Tooling has two Heat Robo inductive shrink-fit heaters from MST Corporation. Heating time for these units is less than 2 minutes, and cooling time is approximately 1 minute.

Using shrink-fit toolholders to maximize tool life is important because the company doesn’t skimp on cutters. It primarily uses end mills from OSG and Garr that have proven effective at high speed machining blocks as hard as 60 HRc. The ball end mills used for finishing operations, for example, have extremely accurate radii to ensure even metal removal rates and smooth mold surfaces. Similarly, the company uses Crystallume diamond-coated cutters for machining abrasive graphite electrodes because they combine hardness with a low coefficient of friction, for excellent electrode surface finishes and long tool life.

With this equipment in place, Quality Tooling began programming high speed machining jobs using its existing CAM package. Although this CAM package worked well for the company’s standard CNC machines, it simply didn’t enable the high speed machine to realize its full potential. The “speed” was not quite there yet, even though the machine was fully capable of it. Cutters approaching corners would slow down too much, and the resulting tool paths were not smooth. In addition, Stephen says cutters sometimes “fell into” gaps rather than smoothly maintaining the tool path and traversing them. This could cause material gouging and tool breakage. At best, welding and re-machining could save the block. At worst, the block was scrapped and all the previous machining time and cost was lost.

In 2004, Quality Tooling began looking for CAM software that was better-suited for high speed machining with its V55. It chose CimatronE, which Brian says was more costly than other CAM packages but offered the features needed to realize the advantages of high speed machining. He also appreciated that Cimatron was not shy about programming test cuts based on actual jobs that Quality Tooling had run in the past, whereas other software companies presented only their own program demonstrations.

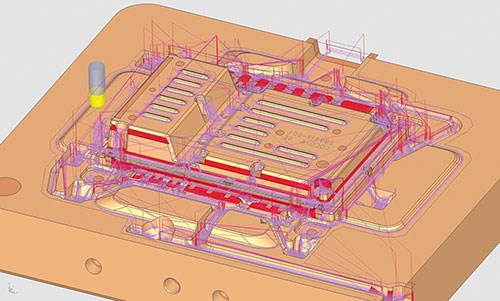

Stephen says the look-ahead algorithms in CimatronE are extremely helpful and have greatly reduced the chance of gouging. Specifically, he appreciates CimatronE’s Knowledge of Stock Remaining technology, whereby the software precisely calculates the stock remaining after each tool path and uses this information to optimize subsequent cutter moves. He says better management of remaining stock is important to prevent cutter crashes and minimize air cutting.

High, consistent feed rates are now possible because the software rounds all tool paths to eliminate sudden changes in direction and minimize jerking movements, Stephen notes. That said, the software automatically adapts the tool path to ensure that rounding does not result in unmachined areas or large scallops, even when cutting sharp corners. Where necessary, it also automatically applies trochoidal machining. Zero-overlap trochoidal machining and tangential approach/retract options help prevent witness marks and scratches on mold surfaces. The software also minimizes scallop size for complex 3D surfaces by varying machining based on vertical or horizontal incline and/or maintaining a fixed 3D distance between passes.

Without the toolpath “stumbling” that was common to the previous software, the higher-priced cutters hold up longer and deliver better finishes. Plus, Quality Tooling can rough more areas of its blocks and rely less on sinker EDM. Today, a typical block might require one or two sinker EDM operations, compared with 15 to 20 previously. The company realizes further time and cost savings by reducing the number of electrodes it needs to machine.

Quoting is more accurate, too, because unexpected gouging has been virtually eliminated. In addition, NC code calculation time is much faster. Stephen says the software can be set up to use all of his computer’s eight cores. Another big time-saver is the ability to process a job while he programs another. Plus, programs automatically update whenever changes are made.

Adding Capacity, Running Lights-Out

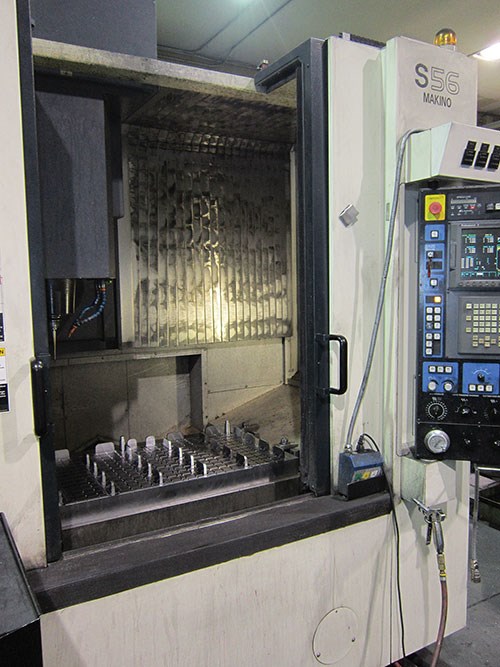

Brian says Quality Tooling’s predictable and efficient high speed machining process enabled the company to win more work by providing faster deliveries at lower costs than many competitors. This spurred the company to increase capacity by adding another seat of CimatronE and two more Makino high speed machines: an S56 in January 2006 and an F5 in April 2012. The F5 is fitted with a Donaldson Torit dust evacuation system and is used for graphite electrode machining as well as finish-machining of mold blocks (see the sidebar below for more information about that machine).

Quality Tooling also quickly realized that lights-out manufacturing would be the next logical step in becoming more productive. This also would enable the company to charge customers at a different rate because there are no employee costs associated with that work.

EDM and milling jobs with short cycle times typically run during one of the two day shifts in which operators are present. Longer-running jobs are set up to run overnight, during weekends or over holiday breaks. Meetings are held every Thursday or Friday to schedule the work that will run unattended over the upcoming weekend. If no long-cycle-time jobs are in the queue, multiple smaller jobs are set up. In those cases, the goal is to make the most use of each machine’s available table real estate while leveraging the benefits of alternate workholding methods.

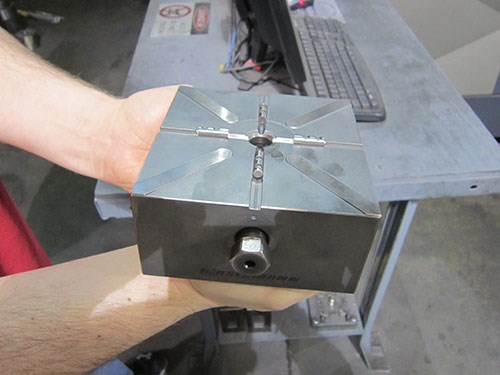

For example, the company uses electropermanent magnetic workholding chucks from Tecnomagnete on its machining centers and sinker EDMs for quicker setups and fixturing flexibility (it currently has six of them). Previously, it machined ledges on the bottom of blocks so conventional clamps could secure the workpieces. It took as long as 30 minutes to set up and indicate a block using this workholding method. With the magnets, this takes only 5 minutes. For milling and sinker EDM work, the company can set up a long-running job on one side of the magnet and leave the other half available for short-run work during attended shifts. That way, operators can pause an uncompleted, long-running job in the morning and set up and complete short-run work during the day.

Similarly, Quality Tooling uses Hirschmann quick-change pallet fixturing systems to speed setups and change-overs on sinker EDMs and machining centers that mill electrodes. Pallets install in receivers in known table locations, making for fast installation and repeatable positioning. Prior to machining electrodes, the company simply saw-cuts graphite blanks and uses a specially designed industrial adhesive to glue the blanks to aluminum plates that mate to the Hirschmann pallets.

Although Quality Tooling has built a high degree of reliability and predictability into its lights-out approach, no process is flawless. Cutters can unexpectedly break, as can EDM wire, which could lead to extended lengths of unproductive idle time. Rather than paying someone to perform these checks in person during off hours, Quality Tooling has installed infrared LED cameras that can pan and zoom to view a machine’s control screen or workzone. Stephen developed a means to assign an IP address to the video feed in order to access the cameras via home computer or smartphone. That makes it easy to remotely check the status of long-running, unattended jobs. If a problem is identified, someone can come to the shop to make the fix and get equipment running again.

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More