AMB 2018 Highlights E-Mobility and Lightweight Construction

More than 91,000 attendees gathered at the AMB trade show in Germany to visit 1,553 exhibitors and talk about the impact of e-mobility, Industry 4.0 and other relevant topics.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Going from IMTS 2018 in Chicago, Illinois, to Germany’s metalworking show AMB in Stuttgart a week later, I’ve seen a lot of similar technologies, machine tools and tooling from global companies. While most of the cutting tools, machine tools, workholding solutions, CAD/CAM and additive manufacturing technologies are globally applicable and sought after by machine shops, I noticed some differences in the way companies set exhibition highlights and presented themselves.

Makino’s booth in Chicago, for instance, was dominated by Athena, a revolutionary new technology that enables operators to interact with machine tools using simple voice commands, which was also on display at AMT’s Emerging Technology Center (ETC) booth, where I tested Athena attached to a DMG MORI machine; and it worked even with what many people say is my distinctive “German-Aussie” accent.

In Germany, there was nothing similar to see on any booth. Makino Europe’s President and CEO Anders Ingemarsson explained that it was difficult to implement Athena in Europe with so many different languages.

Nevertheless, AMB featured many trending topics such as digitalization, Industrial Internet of Things (IIoT), connectivity, artificial intelligence, virtual reality and e-mobility. While many companies are engaged in engine production, there is no great fear to lose much of this business in the short term.

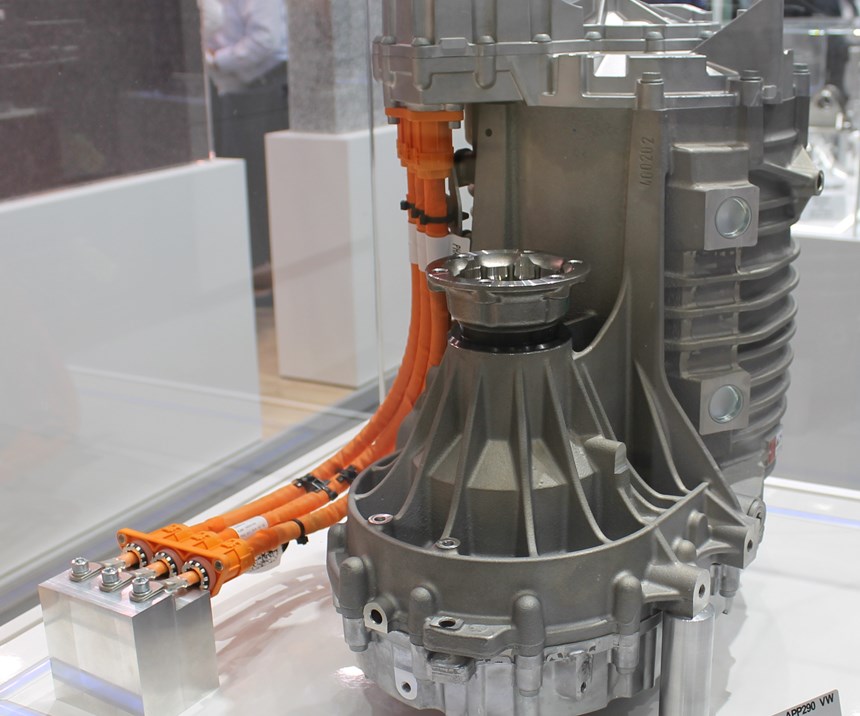

A study carried out by ZF Friedrichshafen AG envisions 90 percent of vehicles worldwide still being equipped with a combustion engine in the year 2030. However, the overall share of hybrid vehicles in this future study is almost 40 percent. Thus, it can be expected that hybrid technology will smooth the transition to purely electric mobility. Consequently, the automotive industry is preparing for alternative drive concepts and a future with an increasing amount of electric motors with different design and machining requirements and cars with a need for even lighter material concepts.

High Demands on Precision

Electric vehicles have a different noise behavior compared with fuel-driven vehicles. Omission of the combustion engine makes the vehicle extremely quiet, so that the tire rolling and the quiet humming of the electric motor are almost the only sounds heard. This increases demands on the noise vibration harshness behavior of the vehicle. Among other things, components in the drive must work together even more quietly and be machined even more precisely to achieve this.

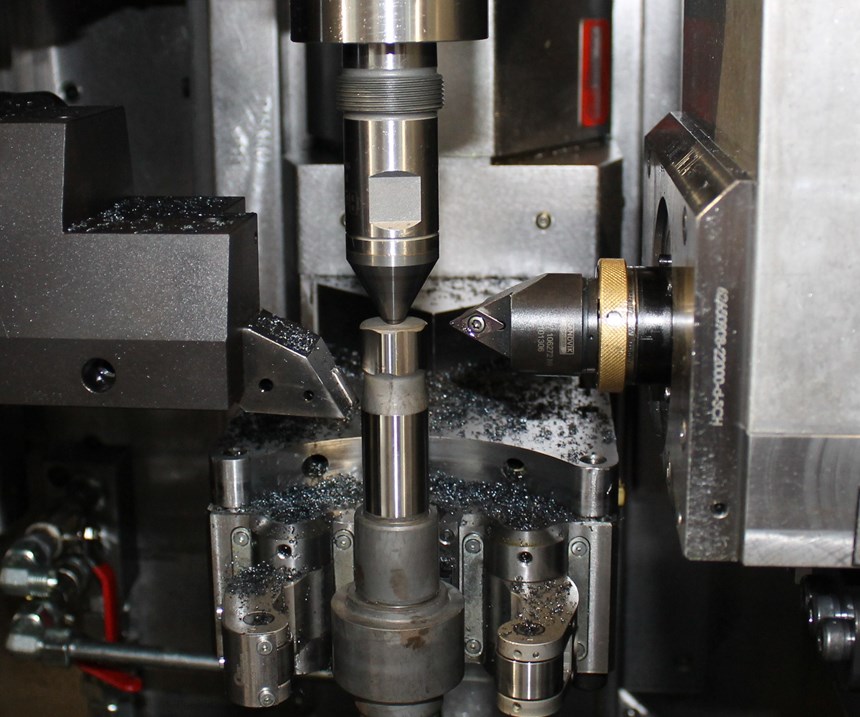

Präwema Antriebstechnik (DVS Technology Group) has developed the Vario-Cross-Honing technology for this scenario, which was showcased at AMB. This technology permits surfaces to be optimized to an Rz value of less than 1 µm thanks to an additional oscillating movement during gear honing, the company explained. Moreover, the Pittler Skive line, a high-performance power-skiving gearing center, enables complete machining of planetary and ring gears for gearboxes including hard- and soft skiving, turning, milling, drilling, deburring and measuring in a single clamping (see slideshow above).

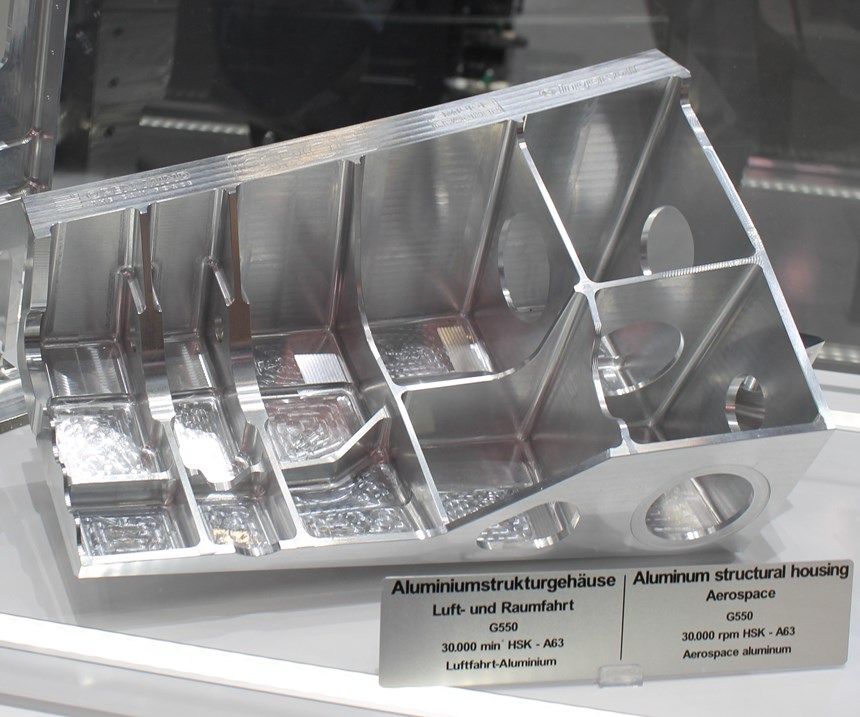

The automotive industry is also increasingly using new materials such as Al-Li either to make components lighter or protect them against increasing strain. Moreover, there are opportunities in new parts such as charging and battery components.

According to Markus Kannwischer, head of technology and member of the Board of Management at Paul Horn, high-precision plug connections, new gearbox components, electric motors and elements in the area of cooling, for example, are required. Although electromobility almost inevitably requires lightweight construction, Mr. Kannwischer does not believe in a further increase in the use of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP). For this purpose, thermoformed steels have caught up considerably, he says. “In general, lightweight construction leads to a large number of new materials that can only be machined economically with adapted tools. Examples for these adapted tools are the use of nano-carbides for machining high-temperature alloys or newly developed coatings and machining processes,” he says.

Machine tools and tools themselves benefit from such lightweight concepts. For example, reaming tools with long cantilevers are sometimes already designed with CFRP shafts.

Other methods for reducing the weight of tools include the use of components made of lightweight materials such as titanium, aluminum and CFRP, weld designs and additive manufacturing. "The reasons for the use of lightweight tools are machining requirements relating to speed, maximum tool change weight, spindle flexibility and improved axis and spindle dynamics. For external reamers in floating chucks, the motivation is the improved workpiece quality,” says Andreas Enzenbach, vice president of marketing and product management at Mapal Dr. Kress.

To prepare for an e-mobility future, machine tool manufacturer Grob purchased DMG Meccanica earlier this year, a leading manufacturer of machines and systems for the production of stators for electric engines, alternators and generators. By its own account, Grob has already worked on several electric mobility projects and increased its research and development work on future technologies through the acquisition of DMG Meccanica. Grob says that it now has all the main processes and methods for producing electric drives for the automotive industry and its suppliers under one roof and can also supply them worldwide tor series production.

The Chiron Group is also unperturbed. Dr. Markus Flik, chairman of the Executive Board of the Chiron Group said, "In the area of electric mobility special components for new modules and units such as scroll compressors, electromechanical brake servos or electric axle drives are required. There is also increasing demand for turbochargers and, thus, for compressor wheels made of titanium. Since titanium wears much quicker than aluminum, sister tools must be used here in order to ensure a productive production process. For this purpose, we offer solutions through corresponding machine series and automation systems."

Related Content

Arch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreEliminating Automotive Defects Per Million With Automated Visual Inspection

This automotive manufacturer virtually eliminated PPM defect complaints after implementing an automated visual inspection system at its facility.

Read MoreFaster Programming and Training Helps Automotive Shop Thrive

Features that save on training, programming and cycle times have enabled Speedway Motors to rapidly grow and mature its manufacturing arm.

Read MoreSchwanog Custom Form Tools Reduce Cycle Times

IMTS 2024: Schwanog’s insertable form tool system supports the manufacture of precision parts for industries such as medical, automotive, aerospace and others.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=150)