Custom Solution Enables Quick Production Of Knee Component

This maker of implantable medical components can now machine the entire outside surface of a knee component in one setup.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreAll manufacturers strive for precision, but that word may take on heightened meaning for those involved in producing medical implants. Even the slightest machining error or deviation from the design can have severe consequences, especially because manufacturing errors may not become evident until the device fails in vivo.

One company that can speak intimately about the challenges of producing just-in-time (JIT) components for the implantable medical device market is McMurray, Pennsylvania-based FPD. This integrated manufacturing and engineering company provides forgings, machined components and assemblies to the aerospace and medical industries.

Recently, FPD found that it needed additional capacity to manufacture a difficult part—the femoral component of an artificial knee system.

“Before bidding the job, we knew we didn’t have the capacity or the machinery to produce this complex part efficiently,” Mr. Bugay says. “We had to devise a way to produce the part more quickly and more accurately than our competitors.”

To offer the flexibility to accommodate different patients, the implant is available in a posterior-stabilized model or a more anatomically correct configuration that retains the cruciate ligament. In addition, instrument standardization and ease of identification keeps the end-user in mind and promotes functional efficiency.

This femoral component has 96 percent femoral/tibial congruency, a deep patella groove and a flared anterior flange to improve patella tracking. Although these characteristics are beneficial in that they promote flexibility, they also create several manufacturing challenges for FPD.

“The customer told us that the surface finish and geometries were so critical that one cannot even touch the final part with his/her bare hands after the final polish,” explains David Tenison, general manager and senior vice president of FPD.

FPD considered grinding process to meet the requirements of the job. However, the company determined that machining would be the way to go. Even though grinding is often suitable for parts with simple surfaces, the process can lead to incorrect geometries, Mr. Bugay says. Over time, grinding wheels wear down, thus altering the geometry of the part.

“Typically, ground parts have many rough blend areas that need to be worked by hand to meet the required tolerances and geometries” he adds. “While this is fine for certain parts, it wouldn’t work well for a medical component that is produced on-demand, such as this one.”

FPD says its dedication to precision is evident in its finishing and assembly disciplines, including hand belting and polishing; multi-media surface texturing; high-energy media finishing and polishing and laser marking. The company leverages a custom design and manufacturing system, which is based on a central database containing 3D solid models of parts and all associated tools. Advanced forging simulation software is used to validate the forging and machining process as well as vital information such as press loads, material flow, temperature profiles and die loads. In addition, CNC programs are optimized to reduce cycle times with toolpath simulation programs.

The company purchased its first Makino machine in 2004 and has acquired several others since then. It currently operates three a81M and five a61 machines.

“We first approached Makino because we felt that it could provide us with fast, reliable and accurate machines,” Mr.Tenison says.

Designed for high-torque, high speed applications, FPD’s a81Ms are employed to run titanium parts for the company’s medical and aerospace customers. The a61s are used in precise production work because of their ability to quickly machine parts with close tolerances and fine finishes.

The part is made of cobalt chromium-molybdenum alloy, which is often used in surgical implants because of its high strength and polish. It employs difficult geometries, especially in the deep patella groove, which has to be precisely machined to reduce contact stresses against the tibial insert.

“The patella groove is difficult to machine because it has steep, constantly changing angles and smooth lines,” explains Thomas Bugay, FPD’s production superintendent.

“Compounding this difficulty is the smooth, sweeping geometry of the profile tolerances and the fact that the final assembly is actually completed by the surgeon during the implantation procedure,” he adds.

Inaccurate tolerances could increase the wear rate of the implant, causing additional medical problems for the patient.

“We have a very capable engineering and design process,” commented Tenison. “However, since the femoral component presented such complex challenges, we decided to engage Makino’s Turnkey Engineering Services to determine the most efficient design and manufacturing process.”

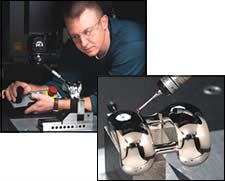

“The goal of the project was to deliver a complete process that accurately and in a timely way machined the entire outside surface of the knee component in just one operation,” says Mike Boyd, Makino application engineer who was in charge of the FPD turnkey. To achieve surface finishes of 16 Ra and cycle times of less than 40 minutes per part, the solution had to include the proper machine, options, tooling, fixturing, coolant and CNC program.

“Tool life was a concern, and after many tests, a Hanita Vision series carbide end mill that yielded the best tool life was chosen,” Mr. Boyd says. “FPD also uses a shrink-fit holder to improve runout and clamping power. Because getting production up and running quickly was a concern, we chose a fixture and CAD/CAM software that the company was already using.”

A Parlec tombstone, which enables the company to mount eight parts at once, provides quick-change tooling plates to accommodate the six different part sizes. Using the a61, FPD can machine the component to ±0.0005 inch profile and ± 0.0025 inch datum tolerances on one machine.

The a61 was configured with several options to ensure proper machining of the knee component’s sweeping geometries, including Makino’s Super Geometric Intelligence. According to the manufacturer, this option allows precise axis motion using small block point-to-point movements while maintaining fast feed rates and high quality. In addition, the dynamic fixture offset option was selected to eliminate the need to re-post CNC programs for any minor fixture adjustments. This calculates the difference between the theoretical location of the part and the actual location.

After machining, the part is hand-polished to a mirror-like surface finish of 4 Ra or better. The resultant surface finish is so fine that the user can handle the part only with gloves, as contact with bare hands could scratch it.

Using this new process, the company can meet the needs of the medical device manufacturer and deliver finished components on time, every time.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)