How Voice Recognition Will Transform Machine Tool Technology

Sponsored ContentFor now, new voice recognition technology is a way to more efficiently run a machine tool. Soon, it will provide access to a whole world of shop floor information.

Share

OK, you probably haven’t been sitting around thinking that you need to be able to talk to your machine tools. But in time you will, and that time is coming a lot sooner than you may suspect.

Voice recognition software was one of the star attractions at this year’s IMTS (International Manufacturing Technology Show). Early adopter and leading machine tool builder Makino already has voice control technology working on several machining center models.

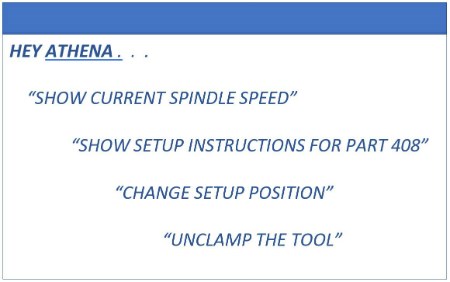

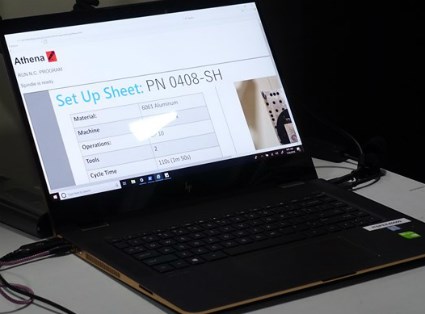

For now, it is a hands-free way to execute a number of control and information display functions—one operator to one machine—with commands like, “run part-program 208 . . . stop coolant . . . change tool to T-15,” and so on. It can provide instant access to CNC information that otherwise requires wading through the CNC interface to find things such as machine settings or maintenance history. It can also serve up critical job documentation such as setup sheets.

See what Makino’s voice activation interface can do now, and in the future.

These functions will not only assist less-experienced operators still learning their way around a specific brand of control, but can bring greater efficiency to even the most skilled machinists, by freeing up their time to focus on more complex tasks.

The next step will be having the same interface work for all your machines, regardless of brand or control. And ultimately, the voice-activated human-machine interface (HMI) will provide access to your entire shop floor network, with connectivity to machine monitoring and predictive maintenance applications, process control documentation, ERP systems and more.

Too good to be true? All the components of this technology already exist, and now it’s a matter of integrating them with more production equipment and software applications that control the shop.

Meet Athena

Makino is leading the way in advancing voice-recognition HMI technology in machine tools, but it’s not doing that on its own. The company is working with the company iT SpeeX, developer of Athena, which they call “the first universal, voice-operated assistant technology specifically designed for manufacturing work.” If the name Athena reminds you a bit of Alexa, it’s strictly intentional. But it’s capable of doing much more than play music, turn the lights on, and give you the weather forecast.

Even in the early stages of development, Makino believes a voice-recognition HMI can deliver significant benefits. Makino CEO Don Lane says it fits his company’s culture of customer enablement. “We believe it can help every customer operate even better,” he says.

Will you only find Athena on Makino machine tools? No, and that’s the way they want it. The goal is that Athena will become the industry standard voice-activated HMI for a wide range of production equipment, and Makino recognizes that the more builders that adopt it, the better it will be for everyone to achieve higher levels of interoperability and data integration across the shop floor. Makino does intend, however, to integrate the technology further and faster with its machines than anyone else.

At its most basic level, Athena is simply a human-machine interface that uses voice commands rather than an array of buttons to initiate machine functions. The system consists of a headset with shop-noise-cancelling features and software running on a shop-hardened notebook PC. The operator uses the headset’s microphone to give commands and ask questions—virtually any command that might be reasonable to issue to the CNC and virtually any question relevant to the machine or job. For any command driving a machine motion, the system checks its understanding of the human operator by restating the command as a question and listening for “Athena, yes.”

No doubt, an experienced operator can interact with a CNC efficiently. But that proficiency might not easily translate to another control. Instead, operators who are adept at conversing with Athena could be deployed as needed to any CNC machine, without concern for the control model. Overall equipment effectiveness (OEE) will then increase because the users of that equipment will be more effective. The benefit will be even more pronounced for less experienced operators.

The Bigger Picture

Today: one Athena headset to one machine tool. This is the model by which the technology is being beta field tested and refined. The next step is wireless connectivity suitable and compatible for the entire shop floor, allowing one operator to engage with many machines. Ultimately, several headsets will be used for a variety of roles within the shop, with various employees possessing different levels of access to command or query machines depending on their different roles.

Initially the voice-activated HMI will provide instant access to machine control functions and key documentation. Down the road it will access a wide variety of shop floor information.

A particular advantage of an industry standard HMI like Athena is that, once multiple machine builders adopt it, it will simplify interacting with different makes and models of machine tools and controls. For example, a voice command of “adjust feed rate to 520 ipm” will sound exactly the same to other brands that support the standard as it does to a Makino machining center. It’s a reasonable question as to how many other vendors will integrate Athena with their equipment. But iT SpeeX is off to a good start with four different machine tool builders displaying it at the recent IMTS.

The initial payback of a voice-activated HMI in a single operator-to-machine scenario is enabling quicker and more accurate execution of non-productive tasks, particularly during setup, and aiding in routine but necessary maintenance functions. But the big payoff will be when that interface gives anyone in the manufacturing enterprise immediate access to the information they need to do their jobs.

Voice Control Technology Is Here

Makino’s application of Athena is Industry 4.0 in action. It takes concepts of digital connectivity and combines it with real, practical opportunities for efficiency. Digital shop floor connectivity is already a gold standard for successful manufacturers. Athena aims to pair that with the success and growing interest in voice technology that we’ve already seen in our daily lives with things like Siri and Alexa.

Admittedly, this may be difficult for some people to see right now, but there are plenty of examples all around us we now take for granted. Makino’s product marketing manager, Dave Ward, compares it to a camera phone: “Ten years ago who would have thought we needed cameras integrated into our phones? Today, the best camera to have is the camera that you have with you.”

The same can be said for voice-control technology with smartphones. What originally seemed like a gimmicky commodity is now a simple means of finding answers, buying products and connecting devices.

In the same way, the possibilities of Athena will continue to advance as data and information continue to become more readily available and easier to integrate across the shop floor. Just like with smartphones, greater value for Athena will be found as new uses are developed for it, perhaps through users realizing possibilities its inventors have not seen. For example, what might come when enterprise resource planning (ERP) data become readily and intuitively available through Athena alongside all the machine and job information?

Maybe that seems like a far way off. But consider voice-control technology is already transforming the way we learn and connect devices. Now is the time to see it in action on the shop floor.

Go here for more information on Athena and other digital capabilities from Makino.