Hard Milling Reduces Lead Time, Manual Labor

Investing in a hard milling machine from Makino has enabled this fineblanking manufacturer to reduce lead time by 55 percent, reduce manual labor and improve part quality.

Share

Hard milling has become increasing popular in recent years as machines with higher speed capabilities, coatings that prolong tool life, CAM tool paths that avoid abrupt changes in direction and other technologies have advanced and become more accessible. Taking light passes at high feed rates and spindle speeds can produce complex parts in hardened material faster than EDM and other processes traditionally used to perform such work.

However, speed isn’t the only advantage of hard milling, as one manufacturer discovered upon installing a machine designed for this technique, the V33i from Makino (Mason, Ohio). "We purchased a hard milling machine with the intent to reduce lead times," says Beat Andres, toolroom manager at Feintool Cincinnati. "What we got was near jig-grinding accuracy, labor-free surface finishing, unattended machining capabilities and improved punch quality."

Founded in Switzerland in 1959, Feintool began as a manufacturer of machinery for fineblanking, a manufacturing process used to quickly produce large numbers of accurate, stamped parts. Today, the company has four divisions and technology centers in Switzerland, the United States and Japan. In addition to producing and selling fineblanking machinery, these technology centers operate as full in-house production facilities serving the automotive and electronics industries.

One of these technology centers is housed at the Cincinnati, Ohio facility where Mr. Andres works. Feintool Cincinnati was founded in 1978 with the objective of developing new application areas for fineblanking in the U.S. market, where the technology was still largely unknown. At the time, the facility consisted of a 45,000-square-foot production area housing five fineblanking presses and 19 employees. Since then, the production area has tripled in size to 135,000 square feet. It now houses 200 employees and more than 20 presses, some of which are rated as high as 10,000 kN. "We optimize designs specifically for the fineblanking process, machine the punches and fineblank the final parts on presses built by our company," Mr. Andres notes.

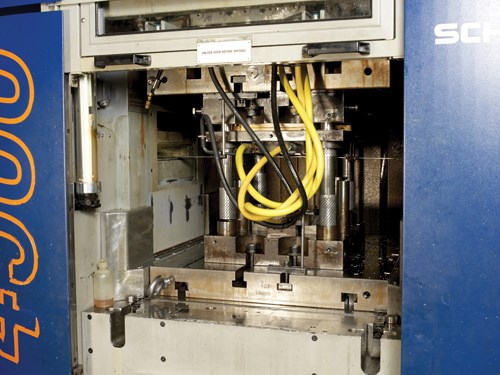

A fineblanking press operates by compressing a sheet of material, such as copper, steel, brass or aluminum, under a hardened tool punch. Unlike typical stamping processes, a less-forceful counter pressure is applied to hold the part against the advancing punch. This is said to provide a flatter, smoother surface. Additionally, parts almost always come out of the machine ready for use, the company says.

One of the prime advantages of the fineblanking process is that it produces no fractures when shearing. Other benefits include excellent

dimensional control, accuracy and repeatability throughout the production run. Compared to other stamping process, fineblanking is said to be a more economical solution for producing high-precision stamped parts in large quantities.

Fineblanking applications at Feintool often involve critical components of safety equipment for automotive, marine and other applications. As such, these parts must be produced to exacting tolerances to reduce the chance of failure—tolerances that typical stamping processes are incapable of achieving. Compounding this challenge is the fact that these parts are often constructed of hardened material.

That’s why the punches used in the fineblanking machines must be more accurate than the parts themselves, Mr. Adres says. This is easier said than done. Due to the hundreds of tons of pressure and millions of repetitions involved in the fineblanking process, punches, like the parts they produce, must be constructed of hardened materials—often to 60 HRc or harder. While the hardened material provides durable, long-lasting punches, it can be difficult to machine accurately and efficiently. The process traditionally has involved hours of handwork, jig-grinding, sinker EDM or outsourcing to specialty milling houses.

"For decades, handwork and jig grinding were the best options available for obtaining our required accuracies, but hard milling technologies have come a long way since then," Mr. Andres notes. "We began evaluating hard milling machines in 2006 to find one that would meet our needs for repeatability, accuracy and speed."

During this evaluation period, the company worked jointly with Feintool Japan, which had purchased a Makino V22 that performed beyond the Cincinnati operation’s required specs. "Combined with an impressive Makino hard milling presentation we attended at IMTS 2006, that made our decision much easier," Mr. Andres says.

The initial machine of choice was the V33 VMC. However, the answer to the company’s machining needs became clear upon the release of the new V33i in 2008. Today, the V33i is the facility’s busiest machine, operating nearly 24 hours a day. The ability to hard-mill a number of punches that were previously produced via jig grinding has saved time, money and manual labor, says Phil Porter, NC programmer and V33i operator.

Likewise, hard milling has also reduced machining time on punches previously produced via slower EDM technologies. For example, tooth punches that once required two-day lead times can now be produced in just two or three hours, while a clutch plate that was previously machined on a wire EDM can now be completed 50 percent faster on the mill, Mr. Porter says.

However, the old production methods haven’t been phased out entirely, Mr. Porter notes. For example, some jobs still demand jig grinding for finishing. However, even in that case, the V33i provides significant cycle time reductions compared to a full jig grinding process. For example, a punch used to produce a transmission component for an off-road vehicle manufacturer once required 40 minutes to produce on a jig grinder. By completing the roughing and semi-finishing to within 0.05 mm of the finished punch on the V33i, the company has reduced total machining time to less than 10 hours while maintaining the required 0.0025-mm tolerance.

The situation is similar for the shop’s EDM machines. "We’ve done all that we can to avoid the use of ram EDM, but don’t get me wrong. ram EDM can accomplish very tight tolerances and geometric features," Mr. Porter explains. "However, in the time it takes to produce graphite tooling and burn the application, we could already have final parts stamped and out the door by using the mill." As an example, he cites a seating adjustment punch that took a week with ram EDM, including the production of graphite tooling. Now, that part can be hard-milled in one hour.

Mr. Porter cites near-jig-grinding positioning accuracy and spindle rigidity as key features of the VMC. Its positioning accuracy makes tool selection flexible, enabling the company to use end mills as small as 0.3 mm for cutting precise features. This also contributes to Feintool’s ability to produce virtually any needed surface finish with little to no hand finishing, increasing manual labor efficiency by more than 40 percent.

The machine’s sustainable rigidity throughout a wide range of spindle rpms prolongs tool life, Mr. Porter says. Combined with a 25-tool-capacity ATC and chip-removal features, high rigidity provides the confidence to run unattended. Moreover, it enables the company to employ the range of spindle speeds necessary to use very small cutters for hard milling tight-geometry radii common to its punch tooling. As a result, punch quality and life have improved compared to previous processes.

One recently machined punch provides an example of the efficiency gains derived from these advantages. This part required 160 teeth to be machined along the exterior radius, each featuring a 45-degree by 0.02-inch chamfer. Previous machining with an EDM required a full day of hand finishing using a diamond file to achieve the proper chamfer accuracies. Today, the V33i is employed to cut each tooth identically and within specification, completing the punch in 2.5 hours.

As Mr. Porter had no previous experience with hard milling, properly applying the technique would appear to be a daunting task. However, thanks to Makino’s tech transfer program, Mr. Porter quickly became the resident expert. After working closely with Makino application engineer Ken Werbich for one-on-one training, he was able to operate the machine by himself within days of installation. Within a matter of weeks, he found himself running some of the facility’s most difficult jobs. "In just a matter of months, I’ve gone from having never operated a mill to training a second shift," he says.

Mr. Andres says the facility continues to advance its hard milling capabilities. In addition to transferring more punches to the new VMC, the company plans to purchase a second machine as well as an automation solution for lights-out production.

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)