Processing The Process

The high speed horizontal machining centers in this manufacturing cell represent a very efficient process for machining cast iron transmission cases. How the crew runs and maintains this cell represents a very efficient process for making this cell ever more productive and cost effective.

Share

When this six-machine cell was installed in May 2000, at Eaton Corporation's truck transmission plant in Kings Mountain, North Carolina, its performance was impressive. The 40-hp HMCs were able to finish a family of cast iron transmission cases in about 25 percent less time than previously had been required. Production costs for each transmission case also dropped substantially on the new cell.

But what is more impressive is how the cell's performance has improved significantly since installation, thanks to a remarkable approach to continuous improvement followed by the operators and programmers who run this cell. They have found ways to reduce tooling costs, boost speeds and feeds, enhance flexibility, add a critical engraving step without sacrificing process time, and exploit the circular interpolation feature of the HMCs. In fact, the team is on the verge of completing some developments that may allow a drastic reduction in the number of different castings required to cover all of the part numbers produced in this cell—from six castings to two.

The operators and programmers have been systematically re-examining every choice of setup detail, cutting tool, machining parameter, tool path and so on. They have consulted with vendors; they have tweaked and experimented; they have tested and analyzed; they have set goals and time lines; they have been imaginative but disciplined. The results are measured and documented.

According to Lonnie Pettit, product line coordinator, who manages this and several other machining areas in the factory, these improvements have yielded an annualized savings of $340,000.Tooling costs per case have dropped from $8.71 to $6.49, he reports. "Virtually all of these improvements were achieved without the help of manufacturing engineers. The improvements were initiated on the shop floor by shopfloor personnel. That's pretty amazing," Mr. Pettit remarks.

Ron Skibo, who supervises ("coaches," as he puts it) the ten-person team assigned to the line, concurs. "The key has been letting the guys who work with this line take responsibility for its performance. We let them determine the areas where they think improvements can be found and encourage teamwork to go after those improvements."

This processing of the process proves the rule that high speed machining applications are a dynamic, lively affair, even in high-volume, automotive production plants where you might least expect it. Like the innovative aerospace shop or boldly aggressive mold builder, Eaton has been willing to take an unconventional approach by not insisting that a successful runoff of the cell be the last word on its capabilities.

A Big Improvement To Begin With

Before the cell was installed, transmission cases were machined on ten stand-alone conventional machines with each machine dedicated to one operation and requiring a special setup for each operation. At best, cases could be completed in about 70 minutes, although bottlenecks at any one of the machines frequently extended that time.

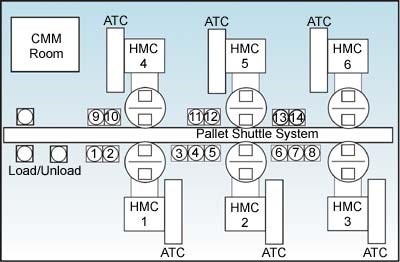

The new cell consists of six A88 HMCs from Makino (Mason, Ohio). These 40-hp machines have a top spindle speed of 12,000 rpm and a 1,968 ipm rapid traverse rate. Tools can be changed in 1.7 seconds, with a 4.8-second chip-to-chip time. The machines are lined up three by three on each side of a pallet shuttle system. Workpieces enter and leave the cell via a two-station load and unload facility.

The transmission cases pass through the cell in two fixturings. First, blank castings are manually loaded upright on "stand-up" fixtures mounted on 24- by 24-inch pallets. These castings come in six variations, including one for the innovative Fuller Lightning transmission (see Sidebar). On the stand-up fixture, the castings undergo a series of milling, drilling, tapping and reaming operations. Afterward, the pallet returns to the load and unload facility, where the cases are hoisted off the fixture and refixtured in a "lay-down" position on another pallet for the second pass through the cell. Fourteen pallets circulate through the cell, seven for each fixturing position. Operations for the lay-down fixturing include face milling the front and rear sides of the cases, boring several bearing journals, and some additional drilling and tapping of bolt holes. The boring operations include those for the main shaft bearing, the countershaft reverse idler and the auxiliary countershaft, plus bearing journals on the interior of the case that must be reached with extended boring bars.

Based on a daily production schedule, the cell controller indicates which kind of casting to load. Then the controller routes the pallet to the first available machine after verifying that this machine is ready with all of the appropriate cutting tools. (Each machine is equipped with a 132-station automatic tool changer.) The Lightning transmission case, however, requires a special set of cutters, including several metric sizes, that is maintained on only one of the machines, so these cases are only routed to that machine. This machine is also tooled for any of the other five styles of cases, so it is never idle.

When a machine is free, it is assigned to the next waiting pallet. The controller calls up the main CNC program for that operation and loads the set of macro routines corresponding to the part number. From part number to part number, variations include the quantity and location of mounting holes for oil pump and non-oil pump transmissions, the location of the reverse idler bearings and different main bearing diameters. Size and location of oil fill holes also vary among the part numbers.

The macros for these machining operations are assembled in modules to make a complete CNC program for each transmission case. This modular approach to programming makes it easy to accommodate engineering changes or to incorporate modifications to the various operations. Only the macros have to be changed. The rest of the program remains undisturbed.

When the cell went online in August 2000, it could complete operations in 21 minutes for the first fixturing and in 25 minutes for the second, counting any waiting time in queue. According to Mr. Pettit, for each operator assigned to the cell, it produced 20 finished cases per shift. By comparison, the original line of machines produced only 10 finished cases for each operator.

Where HSM Fits In

Clearly, the tactical advantage of the Makino cell lies in minimal setup time and minimal non-cutting time. The chief strategic advantage lies in the flexibility to handle any mix of castings and to easily accommodate CNC program changes. However, in this context, HSM techniques translate directly into reduced processing time. In other words, when almost no time is wasted moving workpieces or changing tools, faster feeds and speeds and higher metal removal rates pay off right away.

"We needed horizontal machines that combined fast tool change times and high rapid rates with spindles delivering high torque and rigidity," says Mr. Pettit. "Chatter was also a concern because we wanted to take some heavy cuts on the face milling operations," he adds, "so we looked for HSK-100 style spindles." Other features that were important, he says, were high-pressure coolant through the spindle for fast hole drilling and minimal spindle runout for rigid tapping operations.

The face milling operations represent the best examples where high spindle speeds and high feed rates combine to attain an effect not achievable otherwise. For example, during the second fixturing, the faces of the cases are machined at 0.30-inch DOC and a feed of 60 ipm on the front faces and 70 ipm on the rear faces. The 8-inch diameter face mills run at a surface speed of 2,200 sfpm. The ceramic inserts have a 15-degree positive rake. No coolant is used.

"At these speeds, we get a nice orange chip that carries off the heat," says Barret Cannon, head programmer for the line. "It looks like sparks flying off the cutter, but we know that heat stays out of the workpiece and the cutting edges," Mr. Cannon adds. According to Don Mosley, the Makino sales engineer who led the Makino sales and installation team on this project, heat is a key aspect of productivity in this operation. "The heat generated by the cut moves ahead of the cutter but just enough to anneal the material immediately before the chip is formed. The result is a good surface finish and long tool life," he explains.

The same effect aids the milling operations on the first fixturing. These operations involve smaller face mills but higher speeds and feeds. Milling at 110 ipm and a depth of cut from 0.150 to 0.200 inch is typical.

Process Improvements

Ron Skibo notes that milling operations have gotten a lot of scrutiny in the months after the cell went online. "In several operations, we moved from larger to smaller diameter face mills and reduced the number of inserts. We also found that we could run at higher speeds and actually get better tool life," he explains.

"These improvements shaved enough time to let us add an engraving operation without holding up the line," Mr. Skibo adds. This engraving operation, developed from suggestions of the cell's team of operators and programmers, allows each machining center to mark every case it processes with an alphanumeric. Thereafter, this code identifies which machine processed that workpiece in that fixturing. Engraving this code takes about 30 extra seconds per part in each fixturing. According to Mr. Skibo, the code lets the shop track any quality issues to the source so that only one machine or cutter has to be checked. "The rest of the line stays running," Mr. Skibo says. "Without the markings, we'd have to check every machine to find and fix the problem."

Another opportunity to improve the process lay in the boring of the rear main shaft bearing, a hole that varies in diameter depending on the part number. Originally, this hole was rough and finish bored with two boring bars sized for the operation. Several boring bars had to be maintained in each tool changer to accommodate the various diameters. Now, all of the holes are rough bored with a 3-inch side-milling cutter using circular interpolation. First, the bore is roughed to leave 0.040 inch of stock, and then it is bored to final size with a finish boring bar.

The results of this change are still being evaluated. Because circular interpolation can handle bores of any size, the need to have openings of a certain size in each style of casting goes away. That makes it possible to consolidate the number of castings required. "We're working to get it down to two," says Mr. Petit.

The Case For Fast Holemaking

Because each case requires drilling, reaming and tapping of numerous holes, the fast holemaking capabilities of the HMCs are noteworthy. Each case has 80 to 90 holes to be drilled and tapped.

The most common hole size is 5/16 inch. Most holes are 1.5 inch deep and are typically drilled at 45 ipm. Coolant delivered at 1,000 psi through the tool is the norm. "We're using fine-grain solid carbide coated drills currently," says Mr. Skibo, "but ceramic drills are under study."

Tapping is generally performed at 1,100 rpm, with an infeed equal to the full pitch of the thread. Taps are retracted at two times the pitch. The rigid tapping feature of the HMCs allows the machines to use standard ER-style collet holders for the taps rather than tension/compression holders. "The holders are less expensive, and we can use standard square-tanged taps, two factors that considerably cut tooling costs for our tapping operations," notes Mr. Cannon. He cites the rigidity of the spindles as a key quality of the HMCs for this application. "The rigidity of the spindles and their minimal runout really make this possible," he sums up.

Teamwork

It probably can't be stressed enough that the continued success of this cell relies on the team of operators and programmers assigned to it. Although the cell is highly automated, it has never failed to meet all production targets because it is so well maintained.

The cell generally requires a team of three per shift to handle load/unload duties and perform tool setting activities. To be assigned to this cell, a candidate must be trained in quality procedures; cell operation and function; safety requirements; and auxiliary operations such as preventive maintenance, troubleshooting, environmental compliance and so on. Duties rotate so that each member of the team keeps skills and know-how fully current.

A detailed preventive maintenance schedule is followed rigorously. There are daily, weekly and monthly maintenance items to be signed off on compliance records.

Likewise, quality checks are done on a regular basis. A coordinate measuring machine in a climate-controlled enclosure stands within yards of the cell but serves several other cells and machining lines in this part of the factory. Certain items such as critical bore locations are checked on every case. Otherwise, at least one case processed by each machine per shift is given a full inspection on the CMM.

According to Mr. Pettit, the team assigned to the cell meets once a week. They set performance goals for the cell and prioritize projects that will help them meet the goals. For example, at a recent meeting, the team decided to study drills with indexable carbide inserts as possible replacements for the solid carbide and carbide tipped drills now in use. A plan and a timetable have been developed, with tasks assigned to certain team members. Activities on this project and their results are posted at the cell.

Action items on this plan may include consulting with vendors, who are invited to visit the cell and talk directly to shopfloor personnel. Vendors then make proposals, which the team reviews. Those that the team judges to merit further testing are scheduled for trials. Cost/benefit criteria are carefully identified at this time.

A good example of how this process resulted in substantial improvements was the switch from 8-inch to 6-inch face milling cutters. This change significantly reduced carbide insert usage, which represented the single most costly tooling item. Savings will equal more than $26,000 per year.

Data on the cell's performance is also displayed on charts posted at the cell.

Mr. Pettit says that team activities are self-directed. "We supply the data, but we let Ron and his team take it from there."

Hallmarks

Eaton's machining cell bears all of the hallmarks associated with exemplary high speed machining applications. The capabilities of the machining centers are leveraged by process strategy (circular interpolation in boring operations is a prime example). Machining parameters are highly influenced by testing and experimentation. Vibration and chatter avoidance are key determiners of process choices. Machining center performance is judged against the cell's own record rather than on industry standards.

In terms of managing an integrated process for continually improving efficiency and cost effectiveness, this cell is a worthy benchmark of innovation. "Processing the process" makes it a standout.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=970;quality=90)