Flexible Manufacturing System Shortens Lead Times

A Makino MMC cell and a81 machines provide a flexible production environment that helped Roush Industries take on a wider variety of work with shortened lead times.

Share

Roush Industries is not your typical shop. With its low-volume batch runs, spot buys and custom machining, the company demands a highly flexible production system that can keep up with an ever-changing workflow. By investing in horizontal machining centers and an automated material handling system from Makino (Mason, Ohio), Roush was able to shorten lead times and take on a wider array of part orders without disrupting production.

From its facility in Livonia, Michigan, Roush processes external orders for the automotive, oil and gas, recreational and aerospace industries worldwide. Aside from production, the company is involved with engineering as well as research and development. Because of this, a variety of work comes through Operation Manager Mel Koslowski’s door.

When he joined the company in 2009, Mr. Koslowski came from a shop in which a job would be set up and thousands of pieces would be run for days. This is not the atmosphere at Roush. Instead, part volumes change on a daily basis and the production environment needs to adapt quickly. For example, a machine might be gundrilling 316 stainless steel in one instance, then switch to boring a compacted graphite iron Ford Racing NASCAR engine block within a matter of minutes.

“We don’t have long-term production contracts like many production facilities,” Mr. Koslowski says. “The orders we receive can vary in volume from one part to a few hundred, and may arrive as a single run or repeat jobs.”

To provide the flexibility necessary to maintain Roush’s workflow, the company began using four Makino a81 horizontals, three of which are tied within a 20-pallet Makino Machining Complex (MMC) automated material handling system. The cell’s MAS-A5 control enables the company to use more than one machine on a part that requires multiple operations. The output from the cell is a finished part, eliminating work in process.

According to Program Manager Troy Carney, much of the cell’s flexibility can be attributed to a sizable pallet stock and the large-capacity tool magazines found in each machine. The company recently upgraded its last 99-tool capacity magazine to 137 tools, which has enabled it to keep the cell running unattended longer while taking on a wider array of part orders. Once the tools are loaded, pallets are set up and the job is programmed. The customer can come back at a later date for more parts, and Mr. Carney says it’s simply a matter of calling up the program and loading the pallets. Depending on the part complexity, material availability and machine workload, Roush can turn orders around in as little as a day, he says.

Adjacent to the MMC cell is the company’s fourth a81. This stand-alone machine operates in conjunction with the cell, adding more flexibility to the workflow in situations where order could disrupt optimal product flow within the cell. Most often, this occurs when extended machining processes are required to complete a part or when processes require unique setups not readily available within the current pallet fixtures. Operating within this configuration, Roush is able to increase machine availability within the cell for orders best managed through automation.

“We didn’t fully realize how significant the productivity impact of having the fourth machine working in conjunction with the automated cell would be,” Mr. Koslowski says. “While ultimately we’d love to have it inside the cell, it’s been a great asset that allows us to achieve the absolute highest level of efficiency from the cell.”

In response to rapid business growth in 2012, Roush invested in a second stand-alone a81 to further increase production capacity and provide excess capacity while the automated cell is fully utilized. It also handles jobs not suited for automation. While the high-torque output, 10,000-rpm spindle speed, and 1,969 ipm traverse and cutting feed rates reduce cycle times, Mr. Koslowski says that the significant benefit of the a81s is low chip-to-chip time for tool changes.

“It’s an incredible difference that has huge benefits when you’re running jobs that require a lot of tools, which is something that we do day in and day out,” he says. “But all of the speed in the world is irrelevant if you’re not holding tolerances. We know we can use every bit of these machines’ abilities and still easily hold half-thousandth tolerances.”

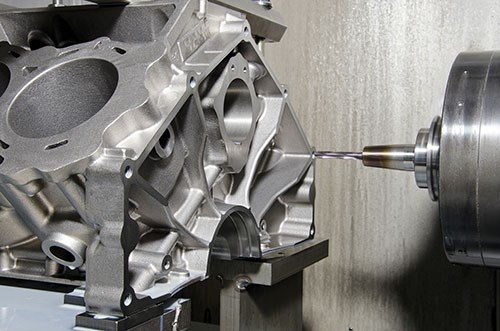

Holding tolerance has helped Roush win bids, particularly for producing auto racing components such as the new Ford Racing engine block. When the current FR9 Ford Racing block design was brought to Roush for quoting, the customer had already experienced issues with a previous supplier. With extremely close positioning tolerance and tight bore-diameter tolerances, it was immediately clear that such critical specifications would set the new standard for accuracy of engine blocks at Roush.

Working together, Roush, Makino and Single Source Technologies (SST) developed a complete processing solution, including tools, fixtures and machine parameters that would enable reliable and repeatable processing on the a81 machines. The company was up and running, cranking out blocks for Ford Racing in a short amount of time.

Another automotive project that Roush uses the cell to produce is high-performance aluminum cylinder heads. According to Mr. Koslowski, this application was made possible only through automation.

“In a purely stand-alone environment, these cylinder heads would not be a profitable order to take on due to their extremely small quantities, short lead-times and stringent accuracies. The flexibility of the MMC completely changes this situation, allowing us to pull up orders quickly with very minimal disruption to our overall product flow,” he says.

To ensure success in the future, Roush is investing in advanced machine technologies. In fact, the company recently decided to turn some office space into shop floor to make room for additional Makino machines. Mr. Koslowski and Mr. Carney are currently evaluating a number of different workflow arrangements to bring on additional automated capabilities, including integrating the company’s current stand-alone machines into the cell and purchasing a sixth a81.

Additionally, the company is considering investments in five-axis machining capabilities. During a recent open-house event, Mr. Koslowski witnessed demonstrations of a Makino D500 five-axis vertical machining center and PS95 VMC. He immediately recognized the impact that it could have working together with the a81 cell. “Ideally, I’d love to integrate five-axis capabilities into the cell while complementing the cell with stand-alone machines. Both of these machines fit the bill,” he says.

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More