VMC Makes Big R&D Strides on Micro Applications

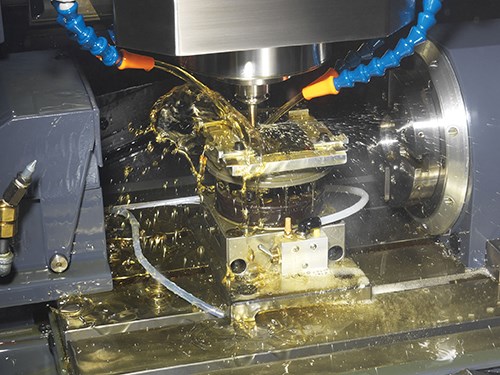

Waters Corp. needed to develop extremely tight-tolerance prototypes quickly, so the company upgraded to a Makino iQ300 VMC to produce complex, low-volume part concepts for R&D.

Share

Addressing product development time while retaining extremely precise tolerances became necessary for Waters Corp. as the company sought to gain a competitive edge in its field. One of the keys to achieving this goal was to rapidly produce prototypes of equipment that was specifically designed to separate compounds at the micro level in-house. By investing in a precision machining platform from Makino, the company indeed was able to speed up product development while achieving tight tolerances on micromachining applications.

At its headquarters in Milford, Massachusetts, Waters develops high-performance liquid chromatography (HPLC) equipment, which is used by research and quality control laboratories to separate and identify components in a mixture by measuring the concentration of synthetic and natural chemicals. HPLC relies on high-pressure pumps to pass a liquid solvent along with the sample mixture through a column filled with minute particles (1.7 microns) of highly refined coated silica that separates the mixture into its individual components. High-pressure tubing and fittings are used to interconnect the pump, injector, column and detector components.

As a trend towards small-particle chromatography emerged, the company began to develop instruments with a smaller internal volume and higher pressure. Recently, Waters’ R&D group challenged the machine shop to pursue microfluidics and improve low-flow liquid chromatography (LC). This would require micromachining tiny columns, tubes and fittings to critical tolerances for channel width, depth and surface finish.

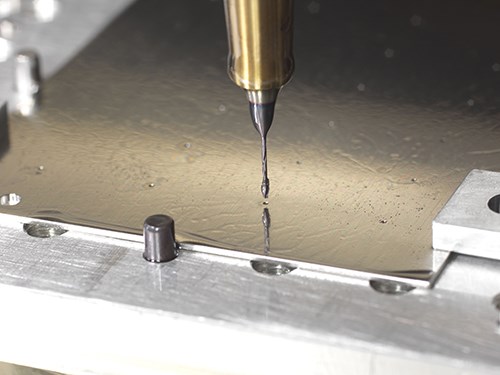

With its previous LC equipment models, Waters was challenged by the fragility of the silica tubing, so it sought to produce the microchannels in a fully contained metal device. This would require the surface finish of the capillaries to be very smooth. The goal was to achieve at least a 5-microinch-Ra surface finish.

The company first tried getting these microparts from outside vendors, but this proved to be very time-consuming. In fact, one of the products took more than two years to develop due to outsourcing, says Bob Jencks, consulting principal engineer. Waters also tried producing the parts on its own, but it struggled with equipment that did not provide the required tolerances and eventually returned it to the manufacturer.

The company then began to research machining equipment with exacting tolerances, high-speed spindles, and exceptional repeatability and tool life. It also wanted a machine that could handle larger features, such as counterbores and ports. It did not want to produce these larger features on a separate machine because of the critical accuracy required of those other features in relation to the microchannels, which do not tolerate any variability. Ultimately, Waters decided that the capabilities of the iQ300 vertical machining center from Makino (Mason, Ohio) fit the bill. The machine is capable of producing the submicron positioning tolerances and surface finishes Waters needed for these parts.

To help make this decision, Waters employees turned to John Bradford, micromachining R&D team leader at Makino, whom they met during IMTS. After discussing possible solutions, members of the Waters team traveled to Makino’s Auburn Hills, Michigan, technology center to see the equipment in action. They sent part drawings to Mr. Bradford ahead of the visit and took along the parts that they had been trying to machine. Mr. Bradford and his team had programmed the iQ300 VMC and selected tools for this specific application before the Waters team arrived and were able to successfully produce finished parts. After three more trips to the Tech Center with additional parts, the Waters team decided to purchase the iQ300.

“We saw that the iQ300 could do the job. In a matter of days, they caught us up on a project we had been behind on for a year,” Mr. Jencks says. “We saw this machine as the complete package. It could do the high-precision micromachining as well as our standard part machining. It was high-end equipment that we could grow with. We rationalized the investment with its ability to get our product out the door faster.”

With the iQ300, Waters has been able to meet all critical tolerances in channel width, depth and surface finish on its fully contained metal parts, just as was done in Auburn Hills with its test parts. In fact, the company has used the machine to enhance performance on several components, producing a variety of features, including channels 0.0060-inch wide and 0.0070-inch deep, says Charles Murphy, senior mechanical engineer at Waters. Positioning adjustments can be made to 0.00001 inch, helping maintain 0.00005-inch true position in critical hole features relative to the microfluidic channels. And while the company requires a 5-microinch-Ra surface finish in its metal parts, it was able to achieve a 1- to 2-microinch-Ra surface finish using the iQ300.

“This level of accuracy and precision is maintained, whether a part runs for four to five minutes or four to five hours,” Mr. Murphy says. “And we can use tool diameters as small as 0.0030 inch without any issues in breakage or tool life. This capability has opened a whole new avenue of product architecture. For us, the size of the fluidic bores influences the behavior of the instrument dramatically. To be able to operate in the hyperfluidic realm—a place where we hadn’t been able to operate previously—has really opened doors for us.”

In addition to having the capability to micromachine, Waters can now create prototypes in shorter time frames than it envisioned, maintaining control over the most critical aspects of product development.

Having this “business within the business” to support R&D has been valuable, Mr. Jencks says. For example, if an engineer changes designs in the middle of making a part, the company can pause the machine, update the model and machine the new feature. Iterations that used to take five to six months to outsource can now be accomplished in two to four weeks in-house, and prototype feedback can be given within days instead of weeks. This means R&D is being completed much more quickly and the company’s next big product idea has the potential to become a reality more quickly, he says.

“Since the iQ300 has come onboard, we’ve been able to develop products we had no capability of developing in the past,” Mr. Jencks says. “The magnitude is greater than anything we’ve ever had in the shop. We have already been able to develop a dozen new product lines that will eventually go to market. For us, it’s not just about cutting faster; it’s the end result. The iQ300 has allowed us to physically demonstrate our confidence to our management that the product concepts we are developing are actually worthy of future development. This machine has made all the difference.”

As Waters moves forward with its research and development, it still sees a lot of opportunity for growth. “There is still so much room to expand using this machine,” says Matthew Howland, machining operations manager. “We have operated it now for almost a year, and we are still learning. There are capabilities we have not even tried yet, and we are looking forward to optimizing our processes even further.”

Related Content

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)