HMCs Help Bow Manufacturer Improve Technology, Productivity

By incorporating a Makino a51nx horizontal machining center into its production process, Mathews Inc. was able to increase its efficiency and keep bow production in-house.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

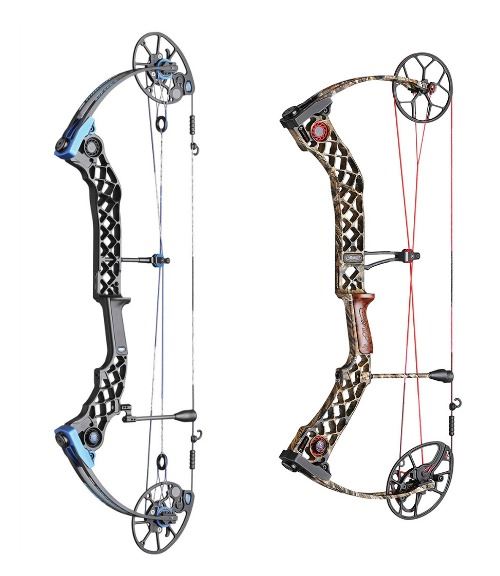

Bow enthusiasts are always on the lookout for equipment that has speed, a smooth draw-cycle, tack-driving accuracy and a dead-silent shot all wrapped in a lightweight package. At least, those are some of the features Mathews Inc. aims for as it strives to continually improve its archery products. In one instance, however, the manufacturer just didn’t have the capacity on its existing horizontal machining centers to accommodate a bow redesign. By integrating Makino HMCs into its operations, Mathews was able to increase its production efficiency for that application and others.

Located in Sparta, Wisconsin, Mathews manufactures and sells a diverse line of archery equipment, components and accessories at independent retailers around the world. As the company’s owner and sole designer, Matt McPherson strives to make his bows better while also making them simpler to use. He and his team are continually working to introduce new designs, technology and products.

Because of this ongoing innovation, Mr. McPherson radically redesigned the company’s main bow from a single configuration to a split-limb configuration. As a result, the way in which the limbs are attached to the bow had to change. Previously, Mathews used a cup system made of aluminum. The new bow design required transitioning from a simple cup produced on a lathe to a more complicated cup system. Production needed to ramp up on this new limb cut, but Mathews didn’t want to outsource the job. The company first tried using its existing HMCs, but the machines just didn’t have the capacity necessary for the job.

On a recommendation, Mathews decided to evaluate machines from Makino (Mason, Ohio), specifically the a51nx HMC, by going into another machine shop to check out the machines in action. The company invited its local Makino representative, Lynn Bachman, who made a solid case for the Makino machine through test data.

“Frankly,” says Scott Jenkins, machine shop manager, equipment and design at Mathews, “we had a good relationship with the other machine tool company and had never really thought about changing machines before. But reliability issues coupled with the recommendation and company reputation piqued our interest, so we decided to evaluate Makino further.”

Still testing the waters, Mathews purchased three more of its existing machines and one Makino a51nx to meet its production demands. The local Single Source Technologies (SST) dealer for Makino delivered the machine, and several Mathews operators participated in the in-house training that SST Applications Engineer Mike Johnson conducted.

“For us, it was an easy adjustment to the a51nx,” says Mike Schlagenhaufer, machine shop production manager at Mathews. “We were already familiar with FANUC-based controls, and the touchscreen interface was very intuitive and user-friendly. Right off the bat, we were very happy with the machine performance. We were hoping to see 85 percent efficiency and were quickly at 87 percent efficiency. Our productivity increased anywhere from 17 to 40 percent on some of our parts. Plus, our other machines were still having issues. This level of performance changed the way we looked at our technology investments.”

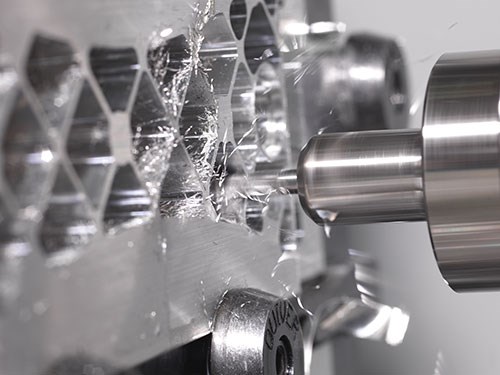

The a51nx decreased cycle time right out of the gate, with one part reducing from 42 to 32 minutes. The machine has a 14,000-rpm spindle, but most of the time saved is in in-cycle, out-of-cut operations. Mathews was running the limb-cup part using window fixturing to get behind the part, which required frequent B-axis rotations. However, the a51nx machine simultaneously conducts its tool changes and the B-axis rotations, which provides faster in-cycle, non-cut times, especially as Mathews creates 224 of these limb-cup parts per day.

“On some of our parts, we are using 15 tools and up to 20 tool changes,” Mr. Jenkins says. “When we are making 16 parts per hour, this adds up. Having the combined movements of the tool changes and B-axis rotations is a big time savings.”

Additionally, the machine is built to be solid and reliable, enabling operators to increase speed while reducing tool breakage. This translates to less vibration in the cut, better-quality surface finishes and tolerances on bearing holes of ±0.0002 inch. The reporting features of the Pro5 control also help operators track this saving and make adjustments to further improve the productivity of the machine. Operators now have the ability to see where cycle-time improvements can be made to reduce feed time on a part. In fact, the saving was already obvious on some parts, says Rich Jerome, prototype technician, fixture design at Mathews.

The company gradually began transferring other jobs to the a51nx, such as a rise part that requires a lot of drilling. Improvements in rapid speeds, which comprised 50 percent of the movement, reduced machining time by 36 percent, from 2 minutes and 32 seconds to 1 minute and 38 seconds per part, in the full run. Makino has eliminated time on wasted motions that can be used for other processes, Mr. Jerome says.

Enjoying the increased capacity and productivity, Mathews purchased another a51nx in the spring of 2014 and began moving other jobs to this machine. One example is a quiver accessory that was transferred from a vertical machining center to the a51nx when the vertical machine couldn’t keep up with demand.

While it’s a no-contest situation to make comparisons of parts transferred from a VMC to and HMC, Mr. Jerome says, at the end of the day, it’s all about productivity and meeting demand. By bringing these parts over to the a51nx, Mathews increased throughput by 180 percent. More parts could fit on a fixture, producing eight parts instead of two, and tooling and cutting operations were pushed to the manufacturer limit without any issues. Cycle time improved by 41 percent, going from 7 minutes and 23 seconds to 4 minutes and 20 seconds per part while meeting production requirements.

“We are most happy with the reliability of the machine and the extra capacity it brings,” Mr. Jerome says. “Frankly, we recognize now that back in the beginning, when we bought three competitive machines and one Makino, we should have instead bought three Makinos. Of the 46 machines on our shop floor, the two a51nx machines are the ones we don’t have to worry about.”

Investing in high-performance manufacturing technology has not only enabled Mathews to innovate, it has also given the company a foundation for quality. That means having full control over everything in the manufacturing process, which starts in the machine shop. Everything is made in-house except the castings and camouflage film applied to the product. Tools are designed based on solid models, fixtures are created and runoff is done on the machines before releasing a part into production. A prototype group designs the fixtures and custom carbide tooling. Then, the parts are run 24 hours a day, five days a week. They are finished and assembled in-house, before Mathews warehouses and distributes its products.

“Everything starts in the machine shop,” Mr. Jenkins says. “It is the heart of the company. It is there that our innovations in technology are achieved, and this is due in part to quality vendors like Makino. They build equipment that is efficient enough to give us the capacity to handle record growth and to give us the freedom to pursue new and innovative designs.”

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)