Precision Metrology Supplier Relies on HMC Accuracy

Global metrology supplier Quality Vision International produces critical measurement equipment components in-house to control quality and accuracy. HMCs from Makino enabled the company to not only achieve the precision required for components of one multi-sensor system, but also significantly reduce cycle times.

Share

Manufacturers of precision-engineered, high-end products require sophisticated metrology equipment for effective quality control. In order to deliver the requisite precision, that metrology equipment often must be manufactured to standards that are even more stringent than those of the parts it measures. “We’re fighting the same battle as our customers—always improving accuracy and manufacturing methods so we can deliver superior products,” says Stephen Flynn, president of measurement and inspection equipment supplier Optical Gaging Products (OGP), a division of Quality Vision International (QVI).

QVI contracts some work out to manufacturing partners, but the company produces the most critical components at its in-house machine shop to control quality and accuracy. A few years ago, however, the tight tolerances and high production requirements of components for one multi-sensor measuring system exceeded the capabilities of the shop’s manufacturing equipment. Two HMCs from Makino (Mason, Ohio) not only provided the precision needed to produce these parts, but also significantly reduced cycle times.

Founded in 1945 in Rochester, New York, QVI is a worldwide supplier of metrology equipment marketed under various brands, including OGP, VIEW Micro-Metrology, Quality Vision Services, RAM Optical Instrumentation and Certified Comparator Products. Through these brands, the company offers a diverse product range covering a wide spectrum of industries. Starting with a selection of 50 standard models, the company can also engineer customized measurement solutions for specific customer applications.

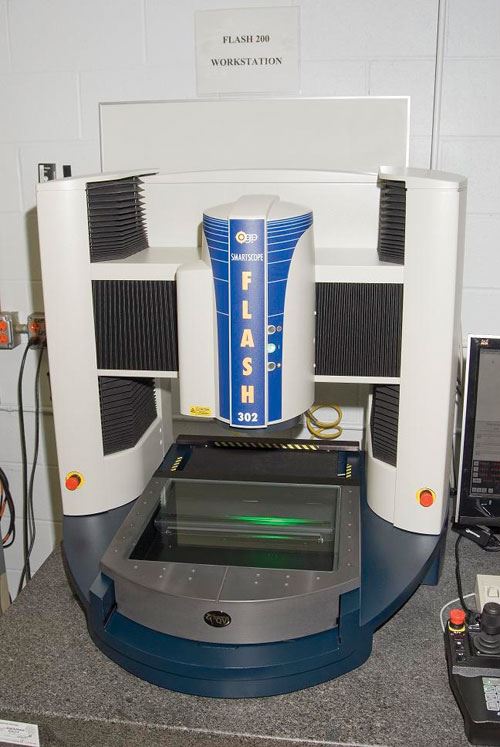

For its part, OGP focuses on multi-sensor systems, which often include lasers, touch probes, microprobes and other sensor types that work in conjunction with video measurement technology. In addition to providing extremely detailed measurements, such systems can inspect more part dimensions in a single setup than their more dedicated counterparts, the company says. “The sensors work throughout the system’s usable volume, so overall accuracy depends on the base-model construction,” explains David Wolf, QVI shopfloor manager. “That’s why we manufacture base-model components here in Rochester.”

A few years ago, two critical components for one particular multi-sensor system, the base plate and X-axis yoke, proved difficult to machine to specification. With a 300- by 300- by 250-mm measuring volume, the SmartScope Flash 302 is the largest benchtop machine in OGP’s inventory. Aluminum comprises 90 percent of its weight. “A key to manufacturing the 302 was a high strength-to-weight ratio,” Mr. Wolf explains.

The shop soon found that meeting the tight tolerances required for the base plate and X-axis yoke was much more difficult in aluminum than the hardened, ground tool steel with which it was more accustomed to working. High production goals and the size of these parts, which necessitated a larger machine, further compounded the problem. “Most machine tools require a sacrifice in accuracy for a larger work envelope, which we couldn’t afford,” Mr. Wolf says. “Also, while profitable machining for us once meant utilizing machine tools long after they were paid for, the 302 required capabilities that could be found only in modern, high-performance machining centers.”

QVI began its search for a solution by evaluating HMCs from several manufacturers based on the specific design and engineering requirements of the 302’s yoke, which moves in one axis and carries the sensors that move on it in a perpendicular axis (the third axis moves across the base). Two of the yoke’s most critical features, a pair of identical bores located on opposite ends of the part, require bore accuracies of ±5 microns and location tolerances of ±2.5 microns. In assembly, the yoke must hold better than 1 arcsecond per inch of travel.

The company settled on Makino’s a61. Whereas most HMCs use a vertical spindle on a horizontal plane, this model features a slant-column structure for a stronger Y axis that resists Z-direction cutting forces, Mr. Wolf explains. “Y-axis straightness travel of less than 10 arcseconds was required, and Makino was the only builder that immediately responded that this wouldn’t be a problem,” he recalls. “In fact, when we measured the a61, we found it exceeded all the listed tolerances—including Y-axis straightness, which we measured at 4 arcseconds.”

Additionally, the machine’s 14,000-rpm spindle enables the use of high speed tools and advanced toolholders that can achieve surface finishes of 0.8 RMS and roundness tolerances of 2 to 3 microns. The level of accuracy the machine provides has also prompted the shop to apply it to other jobs, particularly those involving prismatic components with tolerance requirements that necessitate single-setup production to eliminate stack-up error. Although QVI initially planned to purchase a $50,000 trunnion fixture to accomplish this task, the a61’s rotary table provides sufficient positioning accuracy to machine these parts without extra equipment, Mr. Wolf says.

As for the requirement to produce parts fast enough to meet demand, the a61’s rapid acceleration/deceleration rates and 0.9-second tool changes have helped reduced cycle times for the yoke by 50 percent, Mr. Wolf says. Another contributor to faster cycles is a multi-sided fixturing vise that enables machining of multiple sides of the part in a single setup. He adds that the machine’s robust construction keeps downtime to a minimum. “We had come to expect way-cover replacements every two to three years, which often entailed long periods of machine downtime, but the a61’s way covers show no signs of degradation after two years of heavy use.”

Way covers aren’t the only components of the machine that have held up over time. After a year of service, the company performed calibration tests to qualify and verify the a61’s accuracy. Results showed an average straightness accuracy error for all axes of less than 3 microns. Eric Gesner, QVI’s chief metrologist, attributes that performance to the machine’s design elements, specifically citing its rigid construction and features such as glass scales.

Using Etalon LaserTracer volumetric accuracy test equipment, Mr. Gesner was able to further tweak the machine to realize submicron positioning accuracies. The Etalon software outputs a volumetric error map that is downloaded to the machine’s Fanuc CNC, which features a 3D error compensation option. Verification of the straightness errors after volumetric compensation showed a threefold improvement with an average of less than 1 micron of error in all axes.

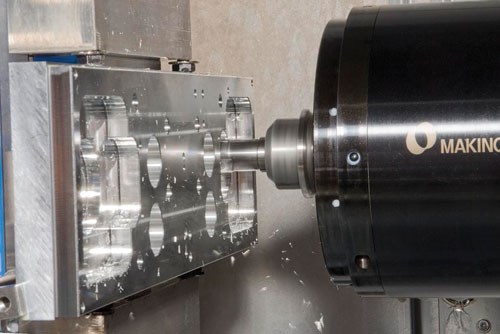

However, a different Makino HMC, the a81, also contributed significantly to speeding production, especially for the 302’s base plate. The shop’s previous machines took too long to remove the large amount of metal needed to produce this component, causing backlogs. Since installing the a81, roughing times have been reduced by almost 70 percent while still achieving the 5-micron tolerances required for the part. Mr. Wolf says the a81’s two-pallet system, which enables fixturing additional base plates, helps to further reduce out-of-cut time and increase throughput.

Improved roughing accuracy resulted in a faster final finishing process for the base plate, the slowest operation of all because of the straightness and perpendicularity of the 302’s structural supports. This has enabled the company to realize a much quicker return on its investment in the a81, Mr. Wolf says.

“Being a leader in measurement equipment requires producing parts with accuracies beyond customers’ required specs,” he concludes. “With the results we’re seeing out of our a61 and a81, we’re more excited than ever to push the envelope of measurement standards.”

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)