A Production Line Takes Shape

Although Pointe Precision built its reputation on low-volume, high-complexity aerospace and medical parts, its expansive high-volume production line may be its biggest success to date. Sound decision-making and attention to details at every step are the keys to this success.

Share

The facts about Pointe Precision’s new production line are remarkable. In less than three years, it grew from four machines to 32 identical HMCs. The line runs 24/7 and has an average machine availability of 95 percent or higher across the entire line. The machines produce a family of six part numbers in volumes ranging from 2,000 to 3,000 a week from a 400-series stainless steel, holding or exceeding positional accuracy of ±0.0001 inch.

This production line is a striking contrast to the shop’s “normal” business of serving customers in the aerospace, paper, fluid power, medical and other industries, all of whom turn to Pointe Precision for high-precision parts manufacturing of a low-volume/high-complexity nature. This work is performed on a variety of multitasking machines, cylindrical grinders, Swiss-type lathes, horizontal and vertical machining centers, and EDMs. From 1,700 to 1,800 jobs are active in this part of the shop. Prototype work is also in the mix.

“The opportunity to move in the direction of long-running, high-volume work was a natural step for us. Operating, managing and maintaining this line are very different to what we were used to, but we were basically building on our job shop skills of making clear, bold decisions and concentrating on details,” Joe Kinsella, president and CEO, says.

Some of the most critical decisions involved the choice of machine model for the line and how to staff this line for round-the-clock operation.

A New Start

In the mid-1990s, when a large manufacturing facility in Stevens Point, Wisconsin, was closed as part of a corporate consolidation program, a sizable number of experienced employees decided to remain in the community rather than relocate. One of those individuals was Mr. Kinsella, who had been part of the plant’s manufacturing management. Recognizing that the most important asset of a successful manufacturing company is a skilled workforce, Mr. Kinsella saw an opportunity to create a new company dedicated to precision machining and relying on the capabilities of this workforce.

The building vacated by the corporate move was available and well-suited for CNC machining operations. Mr. Kinsella formed Pointe Precision at this location as a precision machine shop, equipped with mostly used but well-maintained CNC equipment. Leveraging this top-notch shopfloor talent and adhering to a philosophy of one-stop shop manufacturing capability, the company grew rapidly in its first years of operation. Mr. Kinsella maintained this momentum by investing in the latest CNC technology and constantly renewing the skills of his workforce. “We never got behind in either what our machines could do or what our people could do,” he says.

After nine years of steady growth, the company had run out of space in its original location, prompting a move to a purpose-built facility in nearby Plover, Wisconsin. The new building was designed to create the right environment for its people and its equipment. It is fully climate-controlled, energy efficient and furnished with ample amenities for employees.

Then three years ago, one of the company’s customers approached Mr. Kinsella with a proposal to make Pointe Precision a supplier of a critical part for its recreational products. Demand for these products had outstripped the company’s ability to keep pace. Would Pointe Precision duplicate its machining process to handle the overflow as well as expand to keep up with additional growth? Mr. Kinsella was interested but cautious. High-volume production work would be a new dimension to the company’s strategy of diversifying its operations and customer services. At the same time, meeting the rapid ramp-up requirements in a new mode of operation would be a challenge. “The deciding factor in favor of this venture was our confidence in the can-do shop culture that exists at Pointe Precision,” Mr. Kinsella recalls.

But once that decision was made, other big decisions piled on quickly. Perhaps the most important was the choice of machine for this production line.

HMCs Needed Now

“This customer wanted us to duplicate its existing process—same machining operations, same part program, same cutting tools and fixturing. They wanted us to match the same brand and model of machine tool, as well,” says Sam Crueger, director of engineering services. This immediately posed two obstacles—machine availability and machine suitability. “Because some machine tool builders were still recovering from the production slowdown brought on by the Great Recession, matching the customer’s machines would be difficult on the timeline this customer set for us,” Mr. Crueger says. “In addition, we thought this opening might give us a chance to improve upon the production requirements by reducing cycle times and increasing machine efficiency.” At the time, Mr. Crueger also believed that close attention to details would provide this edge—and attention to details was an integral part of the company’s culture.

The builder in the best position to deliver the machines that Pointe Precision needed was Makino (Mason, Ohio). Makino’s distributor in the region, a branch of Single Source Technologies or SST (Auburn Hills, Michigan) is located in Waukesha, Wisconsin. “They had machines in stock and ready for delivery. Because these would be our first acquisitions from this builder, our comfort level was an issue,” Mr. Crueger admits. This soon changed when Carl Lisiak, the sales engineer from SST who began working with the team at Pointe Precision, made his recommendations.

The clear choice for this application, Mr. Lisiak proposed, was the a51nx, an HMC with a 400-mm pallet changer. Test part runoffs demonstrated that this machine—as delivered from the factory—offered a significant cycle time advantage. Time savings were attributed to high acceleration and deceleration of the spindle, high rapid speeds on the axis drives, faster tool-change times (the next-up tool is brought to the change arm as soon as the prior tool is in the spindle), and a worktable indexer that optimized indexing time and “settled in” more quickly.

Features contributing to the accuracy of the machine include a two-tiered linear guide structure that enhances overall rigidity and minimizes

vibration. “The bed is a one-piece casting. The stepped configuration of the guides shortens the force loop formed by the Z and X axes, resulting in an inherently tighter, more rigid structure,” Mr. Lisiak explains.

Another important consideration was the compact design of this machine, particularly in the area of chip control. Chips fall freely to a wide center trough and are augured to the rear, where a conveyor lifts and discharges them to the side. This arrangement enables the machines to be placed closer to walls and lined up side-by-side for substantial space savings.

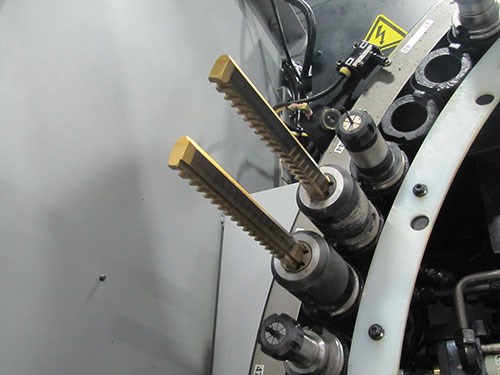

Another significant benefit of the a51nx was the ability of this machine to integrate a two-step push broaching operation, thus eliminating a secondary operation in another setup. The concept proposed by Pointe Precision was to load a broaching tool in the machine spindle and use a downward Z-axis motion to form a rectangular opening (roughly 1.0 by 0.5 inch) in the workpiece. The roughing and finishing broaching tools could be accommodated in the ATC. Makino engineers at the company’s headquarters in Japan were consulted to be sure the machine had adequate thrust and stability to perform this operation successfully. Their tests and calculations proved that this operation was well within the machine’s capability and safety margins.

The selection of this machine appealed to Mr. Kinsella as a business owner. This model did not require modifications or special engineering for this application. Although suitable for high production, this model could be repurposed easily for close-tolerance jobs in medical or aerospace. “This versatility gives us options if this long-running job winds down or if the customer changes direction. We aren’t locked in if we have to shift gears,” Mr. Kinsella explains.

More Machines, More People

The first four HMCs for the production line were delivered in December 2011, just four weeks after the order was placed. For the next 2 1/2 years, new machines were installed every few months in groups of four to eight at a time. When a 25,000-square-foot expansion to the Plover facility was completed in the summer of 2014, several of the machines were relocated to free up space for growth in the job shop side of the business. The 32nd a51nx was put on the floor that fall.

“These installations and moves went smoothly because the Pointe Precision crew and the Makino/SST crew paid attention to details and closely coordinated their responsibilities,” says Brad Cisewski, manufacturing supervisor. For example, the shop had electrical wire drops and air lines in place prior to the arrival of each machine. Cutting tools, fixtures and tombstones were staged and ready for installation. Likewise, on the builder’s side, machine delivery was coordinated with that of auxiliary equipment such as an air filtration unit, high-pressure coolant system and onboard probing systems. “Carl [Lisiak] personally oversaw the setup of each new machine to be sure nothing was overlooked. We never missed a beat,” Mr. Cisewski says.

However, the larger issue of staffing the growing production line proved as pressing as the details of machine installation. “Very early, we decided not to invest in automation, although a pallet delivery system with robots would have been feasible,” Mr. Kinsella says. “We preferred the strategy of developing a workforce of specially trained hires who were not likely to have prior factory or production experience. We could grow this staff as we added new machines, all the while preserving the versatility of the machines by avoiding customized, dedicated systems.”

Fortunately, attracting candidates with a good work ethic and an eagerness to learn proved not to be a problem in central Wisconsin. Pointe Precision hired a full-time trainer and developed a crash course in machine operation. Upon completion of this course, trainees are assigned to work teams operating the production cells, although additional training is ongoing. Work teams consist of 12 members who take 12 hour shifts, four days a week. This arrangement ensures that two teams have all 32 machines covered throughout the day, seven days a week.

Highly standardized procedures and identical workstations enable the team members to be assigned wherever needed in the cells. Each member tends three or four machines as assigned. Communication boards at each machine are available for posting notices, special instructions and performance data.

Each machine is also equipped to accommodate this staffing strategy. For example, a color-coded light stick on the top of each machine provides an easy-follow visual control system. When the green light is on, the spindle is running. Yellow is a tool life warning, indicating that a tool identified on the control panel is soon due for replacement. Red indicates that the spindle is not running and immediate attention is required. A blue light comes on when a pallet is ready to be unloaded of finished parts and replenished with parts roughed on one of four lathes in the cells.

Mounting fixtures on the tombstones are designed to prevent incorrect loading. A broken tool sensor automatically checks for missing or damaged tools that might be obscured by the coolant shower during cutting. A touch probe verifies workpiece location and automatically provides compensation values to adjust for slight workpiece misalignments.

Round-the-Clock Operation

“You start with very reliable machines,” is the answer Mr. Cisewski gives to a question about keeping the production cells running around the clock. “Next, you cover all the details and never let up,” he explains.

The reliability of the a51nx machines became apparent when the first four machines were put into operation. The design and construction of the linear guides, for example, resists wear and requires little maintenance. The ring-style ATC is simple and has fewer moving parts than chain-style toolchangers. Grease packs on the way systems avoid problems with way lube oil contaminating the coolant supply. Only one spindle has been replaced among the 32 machines currently in place, Mr. Cisewski reports.

A schedule of daily and weekly preventive maintenance items is followed strictly. This is facilitated by having all maintenance points accessible from either side or the rear of the machines for “walk-around” servicing. Operator checklists also help ensure good maintenance and housekeeping habits, such as clearing chips that might accumulate under the pallet table.

Effective tool life monitoring enables the operators to keep a minimum of spare tools at the machines and very few duplicate tools in the tool magazine on the machine. Sufficient warning that a tool’s expected life is expiring provides time to retrieve replacements from a central storage location. This reduces tool inventory requirements.

An important aid for supervisors on the production line is the machining results page available at the CNC interface. This page presents a summary of part-by-part cycle times and includes a bar chart that analyzes time spent on rapid moves, spindle on/off, feed holds and overrides, and alarms issued. “This page helps us identify causes of production shortfalls and make sure all the machines are running the same,” Mr. Cisewski says.

One for the Job Shop

Although the number of HMCs in the production line has topped out at 32, at least one more a51nx has been added to the shop’s roster. However, this machine has been installed as a general-purpose machine in the job shop area. “The same qualities and features that make it the right choice for the production cells make it suitable as a workhorse for general machining,” Mr. Kinsella says. “Its versatility, reliability and high precision make it a resource for the demanding aerospace and medical work that drives our contract manufacturing operations,” he says.

Related Content

Horizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreDN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More