Share

One of Athena Manufacturing’s first experiences with automation was this Makino MMC2 24. It has 24 pallets, which supply three Makino a61nx four-axis HMCs with parts.

Automation systems are a major investment. Not only is the equipment expensive, it may require integration and downtime to set up. Shops need to take extra steps to safeguard these investments and ensure they’re not only running as much as possible, but they’re also running efficiently and safely.

Athena Manufacturing is a manufacturer in Austin, Texas, that does machining, fabricating and integrated assembly for the semiconductor and defense industries, as well as other general contract manufacturing. Its equipment includes 15 milling machines (a range of three-, four-, and five-axis VMCs and HMCs), six lathes, and a range of welding and inspection capabilities. It has also implemented several forms of automation, including robots for welding, sanding/surface finishing and machine tending, as well as two pallet systems. As it has invested in more automation, it has invested in technologies, processes and its people to keep these systems running to their full potential.

The shop added a second machine with a pallet changer, this time a Grob G550 five-axis machining center with 10 pallets. At the same time, it added a standalone G550, which it uses to prove out production processes before moving them to the pallet system to minimize disruptions to the automation system.

More Machines

One of Athena’s first forays into automation was a pallet system — a Makino MMC2 24 with 24 pallets that serves three Makino a61nx four-axis HMCs. When the shop added its second pallet system, a Grob G550 five-axis machining center with 10 pallets, it also added an identical standalone G550 to increase uptime on the pallet system. “What we learned from the Makino was during the first part run off, the operator still needs to get into the machine and make adjustments and measurements,” explains Bill Johnson, president of Athena Manufacturing. Operators use the standalone machine to dial in the parameters for new parts, allowing the machine with the pallet system to run continuously. Then, when the process is set for the new part, it’s easy to move it to the pallet system because the machines are identical.

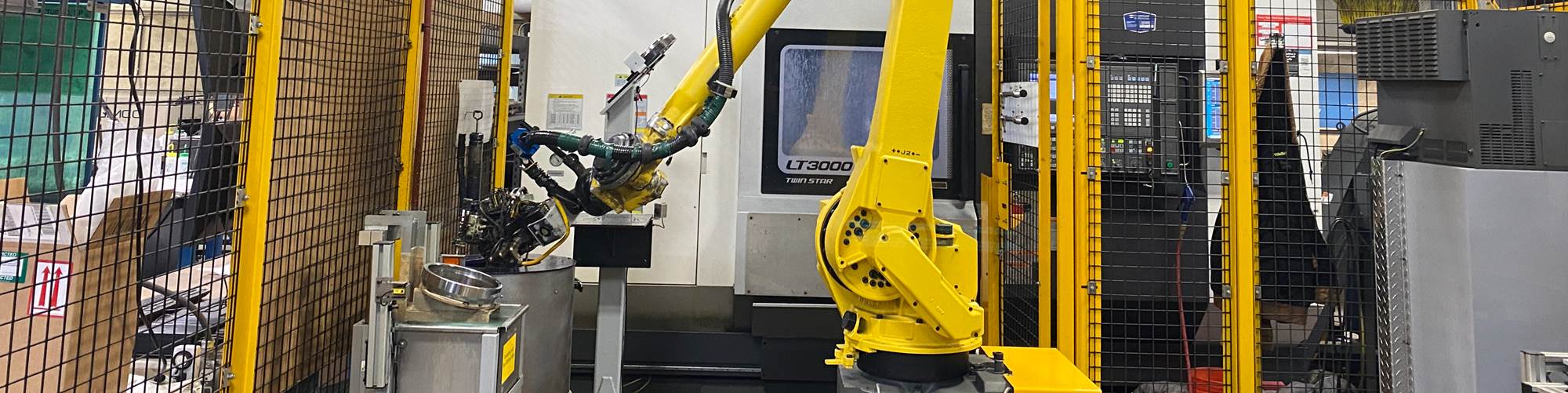

This cell includes a FANUC arm that tends an Okuma LT3000 2T2MY twin-spindle lathe plus inspection and oil dip stations. It produces a single high-volume part number, so Athena Manufacturing wants to keep it running as much as possible.

Can You Tell Me How to Get to Automated Production?

Athena also has an automated machining cell which includes an Okuma LT3000 2T2MY twin-spindle lathe, inspection station and oil dip station tended by a FANUC M-710iC/20L robotic arm Johnson refers to as “Big Bird.” This cell was integrated by Gosiger to run lights out, producing a single part number for the defense industry.

At the end of each machining cycle, the robot removes the op. 1 and finished parts from the lathe, and loads an inspected blank and inspected op. 1 part into the machine. As the machine runs, the arm inspects the op. 1 and finished parts it just removed from the lathe at an inspection station, dips the finished part into oil, moves it to an air blast station to remove the excess oil and places it onto a pallet of finished parts. Then the robot grabs a blank workpiece from another pallet and inspects it. By the time the machining cycle is finished, Big Bird is waiting with an inspected blank and op. 1 part. The robotic arm is even programmed to grab the piece of cardboard that separates layers of parts on the unfinished pallet, transferring the cardboard to a fixture that holds it until the arm moves it to the pallet of finished parts, starting a new layer.

This cell is producing a high-volume part, so Athena wants to keep it running as much as possible. “We invested a million dollars in this machine so it has to run all the time,” notes CFO John Newman. Ideally, it’s only down for a total of 45 minutes each day for an operator to restock it with blanks. But the cell wasn’t running as much as expected. “I used to just get the excuse that it alarmed out,” he says. “Well, why did it alarm out?”

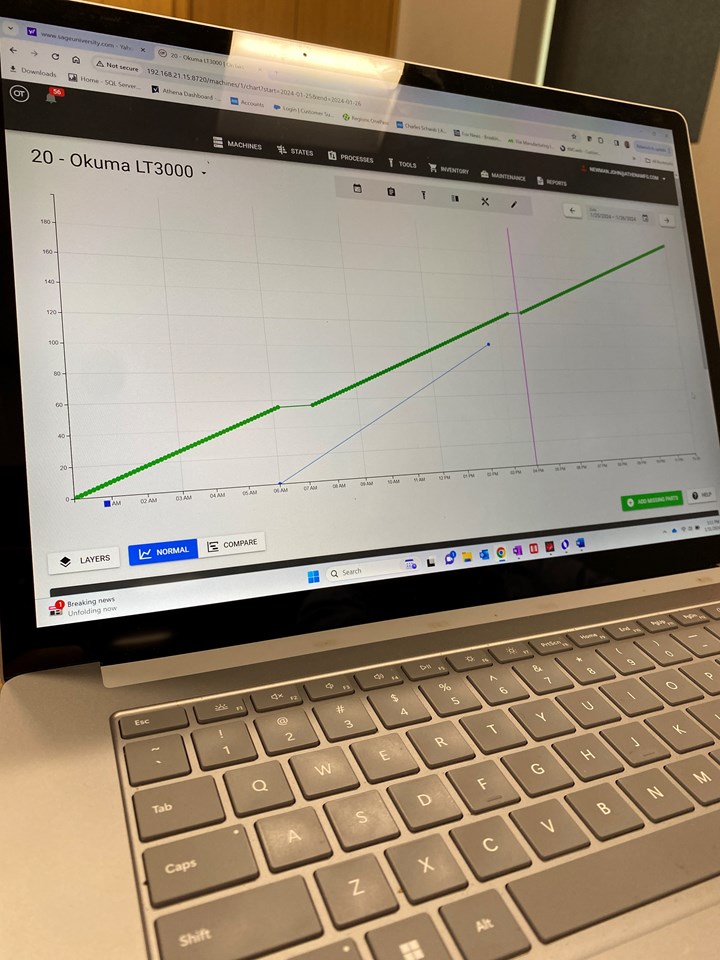

OnTakt machine monitoring software from Wolfram Manufacturing has helped the team identify why the cell goes down, and create checklists operators can use to ensure the blanks, tools and machines are set up properly so the cell can run unattended. “It's really helped us, having the data to resolve issues to keep the machine running,” he explains. “It gives you the evidence to hold your team accountable.”

Machine monitoring software from OnTakt, seen here, helps ensure the cell is running efficiently, and even helps Newman see opportunities to automate other parts on the pallet systems. TMAC software from Caron Engineering helps serve as a safety measure when running lights out.

Data from OnTakt has also helped the company increase production of another of its parts. This is a defense part that runs on a five-axis machine in batches of three. After looking through the OnTakt data, Newman saw an opportunity to build fixtures for this part and run it lights-out on the Grob machine with the pallet changer.

Additionally, Athena uses TMAC software from Caron Engineering for real-time tool wear monitoring and breakage detection. TMAC uses high-precision sensors to measure true spindle motor power and interfaces with the control to automatically adjust for tool wear. Newman says this type of monitoring is necessary in automated environments to not only keep machines as productive as possible, but prevent damage to the machine, especially when running lights out. Athena is using TMAC on seven machines in total, including the two Grob five-axis machines.

Prospering With People

Even with automation, shops still need employees to keep the machines running. Like most shops, Athena has never let an employee go because of automation. “It has allowed the company to be more productive and more prosperous. The robot does the stuff that a lot of people don't want to do for 10 hours a day,” Johnson explains. “And it frees up the human to be creative and think and improve.”

Employees agree that automation makes their jobs better. “I thought it would be difficult to get welders to work with robots and cobots,” says Kyle Naylor, fabrication manager at Athena Manufacturing. “If you truly enjoy welding, which a lot of our welders do, the robots make such perfect, beautiful welds every single time over and over again, and they do get excited about it.” Welding robots haven’t replaced welders, but they have changed their jobs to include tasks such as programming the robots.

But like many shops, Athena is facing a shortage of skilled manufacturing workers. According to Newman, it’s particularly acute in Austin, Texas, where the manufacturing industry isn’t as prevalent as it is in other regions of the U.S., such as the Midwest. “It's a hidden profession, and there’s not much education in that area,” he says.

Athena has taken some steps to help mitigate these challenges. Newman works with the local workforce board, as well as high schools and colleges in the area. The company sponsors a welding program at a nearby high school. Athena has made job offers to all 17 graduates and hired 15 new employees. It partners with Austin Community College (ACC) on an apprenticeship program, which has resulted in 12 students completing the hands-on portion of the program at Athena. The company also has representation on the advisory board for the manufacturing engineering program at Texas State University in San Marcos, and sponsors a senior design project for those students. “We've got ninth grade to four year degree exposure, with some sweat equity,” Johnson notes. As difficult as recruiting is, Newman acknowledges that manufacturers have more resources for training than ever before, thanks to YouTube and online curricula from sources such as ToolingU, which it plans to use as part of its own apprenticeship program launching this year, based on a model from JD Machine in Ogden, Utah.

Naylor is one of the success stories from these recruiting efforts. He started working at Athena doing detail hardware assembly on the weekends while studying welding at ACC during the week. He eventually worked his way up through the ranks to welder, certified welding inspector, welding department supervisor and now fabrication manager. “I learned a lot from starting in assembly and going all the way up to where I'm at now,” he says. “And I still feel like I'm learning because there's new products we develop every day.”

Johnson believes this combination of talent and technology is necessary for shops to succeed. “I think you’ve got to have one eye on getting talent and you’ve got to have one eye on the technical advancement of the industry at the same time,” he says. “And if you don't, if you just look at one or the other, there are missing parts to that equation.”

Related Content

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreEasy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreRead Next

The Culture Change of Large-Part Machining Automation

For Major Tool & Machine in its 75th anniversary year, confronting the skills gap involves a systemized approach focused on automation, and developing and retaining talent.

Read MoreMade in the USA - Season 1 Episode 4: Making the Case for Manufacturing

The majority of Americans want to "bring manufacturing back" to the U.S. The problem? Many of these same people do not want their children to work in manufacturing because of outdated beliefs about what a machine shop looks like.

Read MoreMade in the USA - Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

Read More

.jpg;maxWidth=300;quality=90)