Share

How far can hard milling go? Hard milling’s uses in moldmaking and other high-precision tooling work is well-documented. It skips time-consuming steps like EDM or hand polishing, saving time and money. However, a leading hard milling application is demonstrated by the die-production process at Feintool, where milling even seemingly slight details that once would have been hand-ground has proven vital for realizing repeatability in some of the most precise metalforming tooling. Feintool both manufactures and operates machines for the forming process known as fine blanking. For this company, hard milling has replaced essentially all hand-work operations, and the company is looking at replacing jig grinding as well.

A Fine Way to Make Parts

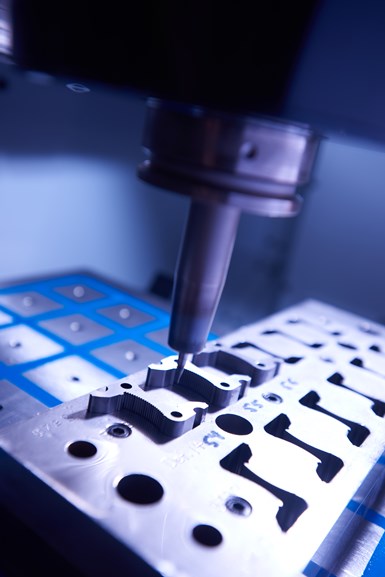

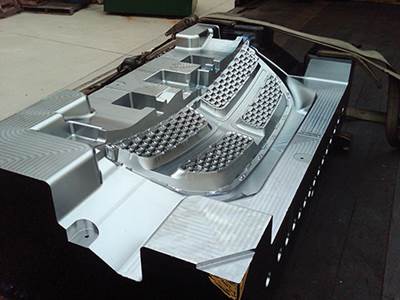

Fine blanking is a precision die-cutting and shaping process for mass producing complex parts. The process is tightly controlled to produce parts needing little or no finishing. All photos: Feintool

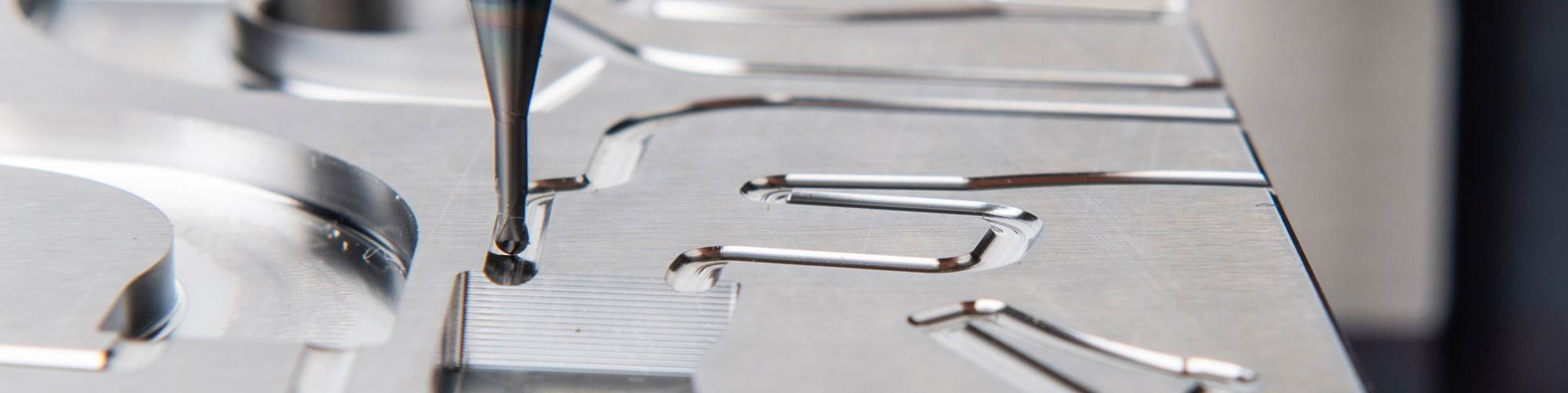

One of the rarer processes that manufacturers come across, fine blanking is a precision die-cutting and shaping process for making high volumes of parts, often with complex structures. Unlike standard blanking, fine-blanking dies have rigid cutting edges with 0.5% clearance between the edge and workpiece, 10 times more precise than that of standard blanking. According to Feintool Executive VP of Sales and Marketing Lars Reich, “The precision and rigidity of the process enables fine-blanking machines to produce thousands of parts per day with excellent flatness, 90-degree edges and excellent dimensional accuracy, with most parts needing no postprocessing.”

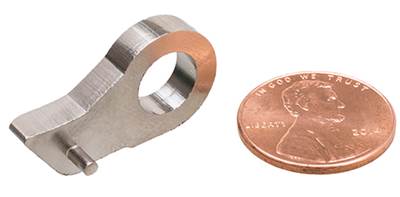

This part was made through fine blanking using the die pictured above. The process produces complex parts in a matter of seconds.

During a fine-blanking cycle, a decoiler feeder unit slides the coil material into position, and a triple-force hydraulic press clamps it into place. Once clamped, the “punch” pushes the blank into the die, which both shapes and shears the metal, stamping a finished part in a matter of seconds. The finished part is then removed, and the machine continues through its next cycle. The process is so controlled that the company’s contract production facility in Cincinnati, Ohio, where it produces parts for customers at rates of tens of thousands per day, has none of the repeated hammer-blow sounds characteristic of stamping, even though the forces are similarly high. This Cincinnati site is also where its diemaking operation using hard milling is located.

Because fine blanking is such a niche operation, Feintool both manufactures the dies and operates the machines on behalf of its customers. The automotive industry has been a major source of work for the company, as modern vehicles require numerous small components with exacting specifications in their engines, transmissions and other systems. “The SUV boom was a major source of growth,” Mr. Reich says. “The second- and third-row seating systems require many fine-blanked parts.”

The dies used in fine blanking are modular, with the individual components assembled after hard milling. This enables Feintool to replace or refinish individual components rather than the entire die as it sees use over time.

Why seats? The gear systems in modern seat-recline adjustment mechanisms have components with enough fine teeth to accommodate around 200 possible seating positions. Machining a part with such fine details and exacting specs at the volume needed for automotive would be cost prohibitive, and stamping would rule out such fine detail, but fine blanking offers a way to mass produce these precise parts at relatively low cost. “Fine blanking really excels when complex, three-dimensional parts need to be produced at high volumes,” Mr. Reich says. Referring to a part like the seat-adjustment component, he says, “We produced a 6-millimeter part at a rate of 50 per minute at a cost of $0.80 each, with $0.40 of that in the material.”

Hard milling set skilled toolmakers free from perhaps their most difficult and time-consuming chore.

The fine-blanking machines can consistently produce enormous volumes of precision parts to some extent because the die is engineered to be modular. Precisely machined steel components that range in hardness from 62 to 64 HRC fit together in the die to provide the shaping and cutting forces. As components wear over time, the company can replace them with new or refinished pieces to ensure the precision of the fine-blanked parts. The ongoing refurbishing of components is part of the nature of fine blanking, and it speaks to why a repeatable method of making tooling — more repeatable than hand finishing — is so valuable.

Repeatability, Geometry, Speed

“We opted to move to CNC hard milling for three reasons,” says Beat Andres, operations manager for tooling at Feintool. “Repeatability, geometry and speed. Speed is the least important of these benefits.” Repeatability was the major draw, as changing out die components means trying to make an exact match to the original. If one of a dozen components is off by a few microns, it will ruin the part.

Moving to hard milling essentially eliminated all hand work for Feintool’s die components. This drastically improved the repeatability of the process when it came to reworking or replacing die components.

Before investing in hard milling, die components were finished by hand grinding, most notably for hand chamfering the leading edge. In addition to being slow, hand work for this vital detail introduced an opportunity for human inconsistency to affect the die. “The chamfering could take all day, which could take a physical toll,” Mr. Andres says. “It was a pain. After two straight hours, you had trouble seeing.” Hard milling not only mitigated that error, it set skilled toolmakers free from perhaps their most difficult and time-consuming chore.

“We have found that more effective milling upstream has power to deliver downstream results.”

The second most important benefit was the range of geometries that were only possible through CNC modeling and cutting. “To fine-blank complex pieces, we needed to be able to make dies in geometries that required three-axis milling,” says Jens-Uwe Karl, VP of engineering. “Our customers’ advancing needs simply made methods like EDM unfeasible.”

The edges of the die components are designed to precisely shear the metal blanks, providing a burr-free finish. The chamfering of the cutting edge profile into the die was once done by hand, but Feintool has moved to hard milling.

Speed, though less important than expanding the company’s ability to manufacture more complex parts with greater repeatability, was still a major draw. Before switching to CNC milling, the company used EDM to manufacture hard die components. EDMed surfaces needed to be hand-ground during post-processing. Hard milling eliminated both EDM and this hand finishing, with additional time savings won by reducing the need to stop production because of inconsistencies in the die.

Doing It the Hard Way

The first CNC machine Feintool bought for hard milling was at its Japanese facility. “Our facility in Japan was physically close to Makino, which enabled that team to work with Makino to develop a process,” Mr. Karl says. “Once they had developed the process, we were able to replicate it in the U.S.”

Feintool chose to use the Makino V33i for its suite of hard milling machines because its rigidity and thermal consistency provided a high degree of repeatability.

Feintool now uses a suite of Makino V33i three-axis milling machines for hard milling. “The V33i has a 30,000-rpm spindle with core cooling, plus core-cooled guides,” Mr. Andreas says. “The cooling systems eliminate thermal expansion, helping to guarantee high repeatability.” The company opted to invest in three-axis machines rather than five-axis ones, as the fixed beds provide more rigidity. The high accuracy and repeatability of the machine tool combined with dimensional stability enables the tool room to run parts unattended overnight and through weekends with confidence.

On Makino’s recommendation, Feintool uses a flood cooling method with a dielectric cutting fluid in place of water-based coolant. This has doubled the lifespan of its carbide ballnose cutters. To eliminate runout, it uses Haimer shrink-fit tooling. “We do everything possible to ensure the repeatability of the process,” Mr. Andreas says. “The rigidity offered by shrink-fit tooling is part of that.”

Using magnetic workholding enables the toolmaker to set up multiple components in each machine. To maximize machining time, the machines run overnight, assisted by automatic tool changers and in-process measurement systems.

The hard milling process also uses magnetic workholding, which not only speeds and simplifies setup, but also maximizes hard milling capacity by allowing room for more die components on the machine table. To ensure repeatability with this system, Feintool invested in highly accurate probing capabilities that enable the machines to quickly locate parts on the plate with accuracy.

Machining cycles are long, particularly with the tiny 3-millimeter ballnose end mills routinely used to machine precise features. Therefore, non-contact tool probing is also vital to applying hard milling effectively. In the event of tool breakage, the machine automatically returns to its position from a previously saved state before switching out tools. Once it returns the tooling to that position, it makes passes over again to ensure it cuts the parts to spec. This safeguard is essential for unattended machining.

Feintool has put a great deal of effort into sourcing cutting tools for hard milling. Cutting tools are sourced from different suppliers after extensive research to ensure the toolmakers are using exactly the right tools for each application.

The choice of cutting tools is the one element of Feintool’s process the company is reluctant to discuss. Much of its process development effort has focused on finding, evaluating and optimizing parameters for cutting tools that perform well in its application. “Picking cutting tools, like everything else in this process, is all about experience” Mr. Andreas says. “No one cutting tool company has everything, which is why researching which supplier has the right cutting tool for each given need we have is so crucial.”

While hard milling has replaced all hand-finishing processes, the company is still not done. “The next step is jig grinding,” Mr. Reich says. He is confident they will do away with this operation. “We have found that more effective milling upstream has power to deliver downstream results, and we are still learning how far those results can go.”

Related Content

Mazak VMC Provides Versatile Machining of Complex Parts

The VC-Ez 20X vertical machining center features a 25-hp 12,000-rpm CAT-40 spindle with a 30-tool-magazine automatic tool changer.

Read MoreThree-Axis Bridge Mill Opens New Doors for Construction OEM

Different industries often require different machining priorities, a truism recently demonstrated by Barbco, an OEM of heavy-duty boring equipment that opened up new design possibilities by pivoting toward rigid, less complex machining centers.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreMitsui Seiki's Compact VMC Offers High-Precision Milling

The VL30 series is designed to machines high-precision mold inserts for medical, packaging, industrial and aerospace applications.

Read MoreRead Next

Keys to Success in Unattended Hard Milling

MMS first visited this shop a decade ago to investigate the requirements for an effective hard milling process. We recently returned to explore the system in place for ensuring that process is reliable and predictable enough to run unattended, often for days at a time.

Read MoreFineblanking Picks Up Speed

A fineblanking press from Feintool Technologies promises to bring the benefits of fineblanking to a wider range of small components.

Read MoreThe Hard Milling Imperative

Hard milling allows mold components to be machined in the hardened state, thus skipping several expensive and time-consuming processes such as electrical discharge machining and hand polishing.

Read More

.jpg;maxWidth=970;quality=90)