Sustainability Project Cuts Costs for Growing Manufacturer

A custom coolant and chip management system has helped Youngers and Sons lower its supply costs, improve its recycling margins and maintain a clean shop floor.

Share

The full PRAB system within Youngers and Sons’ newest facility consists of three main machines: a Vertical Axis Crusher (the dark gray machine in the back), a Diagonal Shaft Chip Wringer (the lighter gray machine in front of the Crusher) and a PRAB Guardian Coolant Recycling System (the blue machine and its attached coolant bins). Images courtesy of Youngers and Sons.

Sustainable manufacturing is profitable manufacturing. Youngers and Sons, a Wichita, Kansas-based manufacturing company serving the oil and gas, agriculture, and heavy equipment industries, has found this to be true as it has expanded. In particular, its efforts toward reducing coolant waste and improving the value of its recycled chips through a custom PRAB coolant management system have borne fruit. The system has helped Youngers and Sons succeed on both objectives, while also eliminating tedious manual coolant management tasks and creating a safer work environment.

Refreshing the Environment

Youngers and Sons is a second-generation family-owned company. Originally founded by Gerald Youngers in 1973, his son Neil Youngers now runs the company, which performs turning, milling, broaching and grinding. In 2020, Neil Youngers solidified a mission for growing the company, with dual emphases in improving employee satisfaction and becoming a leader in sustainable manufacturing. Soon after, the company bought a 51,000-square-foot facility, doubling its available floor space.

Taking lessons the company learned over half a century, it invested in new equipment, including horizontal four-axis mills paired to a 72-pallet exchange system, horizontal lathes with bar feeders, robots and more. With the expanded capacity and capability came an increasing urgency to address its coolant and chip handling. At the time, the facility was unable to recapture any of its coolant, and its usual methods for processing chips left fluid that reduced their value at its recycling partner.

After comparing notes with one of its OEM customers, Youngers and Sons contacted PRAB, a manufacturer of coolant reclamation and chip processing systems, contracting the OEM for a custom system for its new plant.

The PRAB system is the most dramatic and successful project yet in Youngers and Sons’ sustainability journey, but it is not the last. In addition to coolant and chips, the company aims to recycle the water that gets mixed into its coolant and is looking into paper and pallet recycling.

Custom Coolant Management

This system simplifies recycling of 1000-4000 series steel and allows the shop to reclaim its water-soluble coolant after jobs. A crusher reduces the shop’s steel scrap material to flowable chips, reducing the scrap’s volume by up to 90%, with a steel belt conveyor then bringing these chips to a centrifuge that spins fluid from the chips. From there, the chips move through a screw conveyor into storage bins, while the fluid drains into a settling tank. To complete the cycle, an air pump sends the reclaimed coolant into a coolant management system, also from PRAB.

This management system, the PRAB Guardian Coolant Recycling System, uses a wide variety of equipment to clean coolant, with Youngers and Sons’ VP of Manufacturing and COO Chad Hoheisel saying it essentially extends coolant life cycles perpetually. It also automates most coolant management tasks, using a series of pumps to read concentration in different machines, activating itself to mix coolant at the correct concentration and send it to the proper machines.

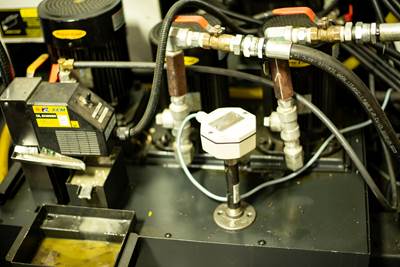

This area was one that needed some optimization from PRAB after the initial installation, as a flow meter sensor in the original electrical pump would get clogged by residue from the coolant concentrate, shutting down the system. Once PRAB learned of this issue, it redesigned the system and retrofitted Youngers and Sons’ system with a diaphragm pump, which continues to work a year and a half after installation.

Room for More

This combination of equipment — the crusher, the centrifuge and the coolant recycling system — has proved effective in meeting Youngers and Sons’ needs. Hoheisel says that the facility has gone from being unable to reclaim any of its coolant to reclaiming about 99.3% of its coolant. Despite the need to still manually feed the crusher every morning from tilt bins, the new system makes the process of recycling these chips much smoother. The facility’s bins no longer show oily waste and the scrap is much higher quality. Youngers and Sons has been able to work with a new recycling company, one that provides better information about the material and any troubles with recycling, giving Youngers and Sons better visibility into how much revenue it can expect from scrap month to month.

Youngers and Sons has been removing both material and time waste from as many operations as possible. It has attached several Makino four-axis machines to a 72-pallet exchange system to increase uptime.

The company’s other production facility is also benefiting from the coolant reclamation and scrap management push. While the new facility was waiting for the completion of its custom system, Hoheisel purchased an interim PRAB system that included the crusher, but not the centrifuge. Now, this system lives in the older facility, where it breaks down the chips and reclaims 65-70% of the coolant — less than with the full system, but much more than the company was previously able to reclaim.

With one system at each production facility, Youngers and Sons has reduced its haul-away costs for metal scrap and fluid by 18%. It has also improved the value of its metal scrap by 12% and reduced new coolant purchases by 38%. Hoheisel says that even considering all the infrastructure and installation work to get the custom PRAB system online, it will pay for itself within 30 to 36 months. Equally important, the machine’s current workload isn’t even close to its maximum capacity. Hoheisel says the system can accommodate about double its current workload — and that’s with the company’s business size doubling in the past three years. Should the business grow further, the coolant reclamation and chip management system is poised to maintain Youngers and Sons’ to create a more sustainable shop, both environmentally and financially.

Related Content

Henkel Redefines Industrial Machining and Grinding with Sustainable Metalworking Innovation

With innovative formulation and bio-resistant properties, Henkel’s new semi-synthetic lubricant emerges as a pioneering solution in the machining industry.

Read MoreSTLE Hosts Co-Branded Tribology, Lubrication Events

The 2023 STLE Tribology Frontiers Conference and Tribology & Lubrication for E-Mobility Conference will provide attendees with two opportunities to share and learn the latest tribology and lubrication engineering science.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreRead Next

Coolant Recycling System Improves Tool Life, Reduces Costs

This Canadian aerospace manufacturer cut coolant costs by 75 percent by installing a PRAB Guardian coolant recycling system, eliminating terrible smells in the process.

Read MoreSustainability at IMTS and Beyond

As sustainability becomes more critical for domestic manufacturing, European and Asian companies are bringing this politicized topic to the American market.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read More

.jpg;maxWidth=300;quality=90)