Automated Five-Axis Cell Streamlines Production

Abipa Canada made its move into automation leveraging a fixture plate distribution system and an HMC, minimizing setup time and lowering part production costs.

Share

Frequently ranking as one of the pricier suppliers during the bidding process was an eye-opening experience for aerospace supplier Abipa Canada Inc.—one that led the company to purchase an automated five-axis machining cell from Makino. The cell helped the company streamline its operation to lower manufacturing costs and produce parts quicker without adding labor.

While the successful integration of automation has helped Abipa (Laval, Quebec, Canada) become a leading Tier 2 supplier of small- to mid-sized aircraft engine and structural components for OEMs like Bombardier Aerospace and Pratt and Whitney Canada, the path to its success was paved with several difficult learning experiences.

Following the recession of 2009, Abipa was recognized for its quality and agility in performance, but it often came in with higher bids. After taking a closer look at its manufacturing process, the company realized that the single biggest differentiating factor in its cost equation was a low machine run time ratio caused by multiple setups, says Rui Cabral, general manager. The shop floor was composed of stand-alone machining centers with an operator stationed at each machine. Approximately one-third of all available production hours were being consumed by setup and maintenance processes. At 5,760 production hours each year, this meant that Abipa was achieving only about 3,840 hours of available machining time.

To bid more competitively, Abipa began looking for a five-axis machining solution that could produce parts at a ratio of at least two to one, compared with its previous process, without adding labor. Additionally, the technology needed to be modular in order to aggressively expand and pursue further cost reductions in the future.

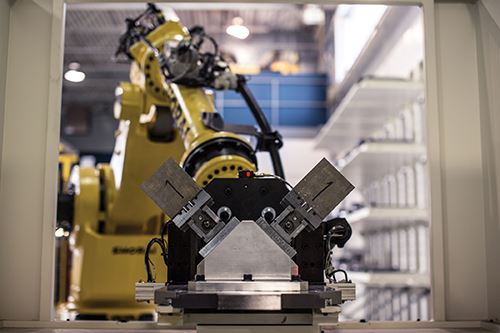

Abipa made its move into automation with the purchase of the MMC-R robotic fixture plate distribution system, equipped with 20 fixture plates, and an a61 nx-5E five-axis horizontal machining center from Makino (Mason, Ohio). Before installing the cell, Mr. Cabral says the company needed to justify the cost of automation and demonstrate that it would actually save jobs by improving the company’s competitiveness. It was important to maintain current employment and enable workers to become better trained and more tech savvy—potentially advancing their careers from operators to programmers or inspectors, he says.

Based on test results from Makino, Abipa calculated that the setup and maintenance hours for a stand-alone a61 nx-5E were roughly equivalent to that of its current technologies; however, the machine’s cutting performance was capable of increasing productivity by 80 percent—the equivalent of 5,949 production hours on its current equipment, says Eric Deconninck, director of production. The production figures grew exponentially when factoring in the impact of the MMC-R system, he says. By eliminating setup hours and increasing spindle utilization to 95 percent, the productivity gains of the machining center were extended, reaching what would have been the equivalent of 9,850 machining hours on the existing systems.

The five-axis machining cell could also provide Abipa with several new manufacturing capabilities such as lights-out production scheduling and a large machine work envelope for bigger parts.

Working closely with Makino and its regional dealership Single Source Technologies–Canada, Abipa’s manufacturing team began to develop an implementation plan including not only the installation of the equipment, but also design and fabrication of the modular fixturing, toolholders, cutters, probing routines, presetter integration and the development of CNC programs for three parts that would represent the various parts targeted for the machine.

The MMC-R cell with a61 nx-5E was assembled at Makino’s headquarters to prove out performance expectations on the three parts. It was installed at Abipa during September 2013, and within weeks, the company was loading orders and producing parts in a fraction of its previous processing times.

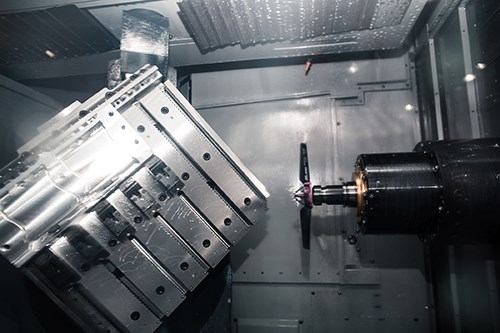

The cell’s performance not only met, but exceeded expectations on several occasions. Depending on the part design and material, productivity has increased anywhere from 85 to 525 percent, says Mr. Deconninck. Production ratios actually rose three to one, and the more material that needs to be removed, the more productive the company is, he says. For example, the cycle time for one of its smaller parts dropped from 58 minutes to 26 minutes. Meanwhile, the cycle time for one of its larger, more complex parts was reduced from 300 minutes to just 48 minutes.

Less than a year after the cell’s installation, it had already exceeded production requirements—and the company hadn’t even fully optimized its process to take advantage of the HMC’s full capabilities, Mr. Deconninck says. Current performance enhancements are scratching only the surface of the a61 nx-5E’s full potential. Today, Abipa is working to perform testing on each part program in order to optimize cutting processes based on the machine’s capabilities. Equipped with a 107-horsepower, 24,000-rpm spindle, the company expects the five-axis machine to see significant performance gains that go beyond initial expectations.

“Of the parts currently undergoing tap testing, we’ve been able to double and even triple feed rates to achieve high material removal rates,” says Nicolas Girard, Abipa director of methods and technologies. “In one application, average material removal rates increased four times. The biggest contribution to this growth was during the roughing process, where feed rates increased as much as 20 times.”

Other process optimization activities in development at Abipa include setup alterations to support reductions in out-of-cut time. The company is evaluating how it can better use the larger work zone in a way that is unique for small to midsize components.

With the previous equipment, it was difficult to produce hole features with tight tolerances for circular interpolation. These features required the company to use a honing machine or boring head, which led to additional setups, teardowns and transfers between equipment. With the five-axis machine, the company can now machine-bore features complete using 180-degree indexing. Diameters are held within ±0.0006 inch with matching alignment within ±0.0002 inch.

While Abipa currently has 85 parts programmed into the MMC-R cell, it expects to grow that number to 500 different parts in the future.

“By choosing to go with the optional 218-tool capacity magazine for the a61 nx-5E, we’ve gained a higher degree of production flexibility,” Mr. Girard says. “This expanded capacity not only allows for a wider selection of onboard tooling, but also affords space for redundancy to keep the cell running unattended longer. We’re also actively developing a standardized approach to tooling and fixturing for quicker, easier setup routines.”

With the MMC-R’s modular expansion capabilities, Abipa intends to add more machines and pallets to the system. The company also expects to add a second a61 nx-5E machine to the cell to handle harder workpiece materials such as steel and titanium. A third and fourth machine are also in the plans to complete the flexible cell as part of a three-phase expansion.

Related Content

DN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read MoreShop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

Read MoreJTEKT Launches New Series of HMCs

The new FH5000 series machines include a 500-mm table capable of handling 1,000-kg loads.

Read MoreGrob Robot Cell Enables Long Periods of Unmanned Operation

The GRC-R12 robot cell features a pneumatic single- or double-gripper system, as well as a drawer feed system with six drawers.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)