HMC Provides Quality Needed for Medical Manufacturing

Big River Engineering and Manufacturing purchased a high-precision Makino a51 HMC to meet FDA regulations and gain customers in the medical device manufacturing industry.

Share

As a medical parts manufacturer, Big River Engineering and Manufacturing needs to meet the U.S. Food and Drug Administration’s (FDA) current good manufacturing practices. To ensure that its products consistently meet applicable requirements and specifications, the company purchased a high-performance horizontal machining center (HMC) from Makino. The new machine enabled the company to replace three vertical machining centers (VMCs), while simultaneously improving finished-part quality and consistency.

Big River has been part of the Memphis, Tenn. community and regional medical-device manufacturing market since 2007, when it was acquired by industry veterans Tom Roehm and Hue Fraser. In 2009, the company moved its operations downtown into a 9,000-square-foot warehouse.

While the company was steadily growing, maintaining this momentum required a better, more efficient manufacturing approach, Mr. Roehm says. In particular, finished parts showed a lot of variation in more complex designs. This would prove to be a challenge as several of its customers began to develop orthopedic products. The company knew it needed to improve both its capability and capacity to earn that business.

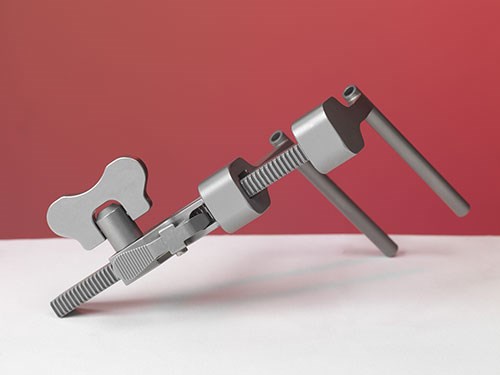

“Producing quality parts isn’t good enough in today’s market. You have to do so while following regulatory standards in a way that remains cost competitive,” Mr. Roehm says. To overcome these pressures, Big River needed a high-performance machining center capable of producing tight tolerances of ±0.003 mm on a routine basis, with a level of confidence that enables unattended operation. It purchased a Makino a51 HMC and added MMC2 automated material handling to double its previous production capacity.

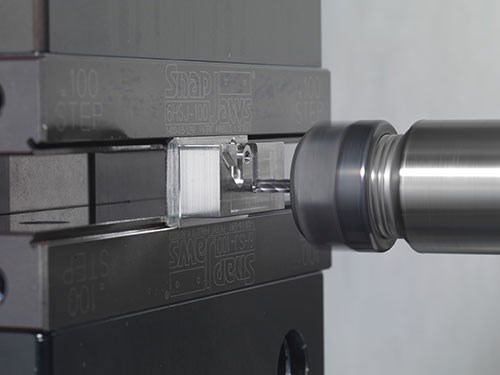

Big River’s a51 cell currently manages 77 different part varieties in materials such as aluminum, titanium, stainless steel and plastics. The switch from VMCs to the HMC provided substantial reductions of in-cycle noncutting times through faster tool changes and rapid rates. Additionally, the 14,000-rpm spindle helped reduce average cycle times by 15 to 20 percent.

“In rpm-related machining using smaller tools, or when machining materials such as aluminum, we’ve seen as much as 40- to 50-percent reduction in cycle times,” says John Monty, operations manager at Big River. “If you combine that with our automated efficiencies, we are achieving a 55- to 70-percent increase in throughput on high-rpm applications.”

Another critical component of the a51 is the through-spindle coolant technology. This feature, combined with the machine’s inherent structural and spindle rigidity, increased tool life by 15 to 20 percent. According to Mr. Monty, these numbers have since increased by an additional 15 percent, following a switch to a premium-grade coolant.

“Through-spindle coolant had a dramatic impact on tooling choices as well as surface finishes,” Mr. Monty says. Fine finishes are a necessity when machining medical parts. All of Big River’s jobs require a 32 microinch surface finish or better. In terms of accuracy tolerances, its customers commonly require ±0.1 mm, but the company likes to take on projects with feature tolerances of ±0.01 to 0.03 mm. Its previous equipment could not produce these tolerances, but the a51 opened opportunities that require a greater degree of precision, he says.

According to Big River, parts pulled from the a51 cell typically feature better fitting in final-part assembly and require less hand finishing. In fact, the FDA capability studies conducted on the a51 cell reflect these statistics, increasing the company’s standings.

Big River says that a significant part of this quality upswing is a result of its newfound tooling flexibility. With improved rigidity and access to higher spindle speeds, the company is able to use smaller-diameter tooling, and it can accommodate additional operations such as deep-hole drilling.

“Our approach to tooling and secondary processes has greatly expanded,” Mr. Monty says. For example, the company has run jobs using a 0.020-inch-diameter ballnose end mill as a finishing tool, and it has drilled holes as small as 0.012 inch in diameter on the a51. Many jobs previously done as multi-piece constructions are now machined complete. Using the a51, the company can achieve more part detail, while removing secondary operations such as plunge EDMing. This increases efficiency and decreases the number of times operators touch the part, which in turn reduces errors.

The automated cell typically runs six different jobs per day, coordinated by the MAS-A6 control system to keep operators informed on the progress. The single-machine/multi-pallet arrangement provides a degree of unattended operation, especially in the evenings and overnight, to increase spindle utilization. To maximize its efforts, the company typically does short runs during the day and long, unattended runs overnight. The MMC2’s pallet delivery helps drive setup time to near zero. Jobs can be set up and fed into the queue without incurring machine downtime. This greatly reduces overall lead times. “Our biggest challenge is keeping the machine fed,” Mr. Monty says. “We do a lot on the front end to make sure the materials are ready to go into the machine.” On a single pallet running 16 hours, Big River experiences utilization rates of nearly 100 percent, he says.

The company is eager to run a true 24/7 operation and is confident about running overnight, due to the accuracy of the new equipment, the spindle probe used to fine-tune positions of the part as it rapidly changes jobs, and an automatic tool-length measurement system that ensures availability of proper-quality tooling.

“Admittedly, the first night of unattended operation was difficult to swallow—not because the machine wasn’t capable, but rather because the process of releasing control was easier said than done,” Mr. Roehm says. “Today, it’s a nonissue. The cell and machine technologies ensure that there are no broken tools, providing for hours of additional productivity.” In the last 11 months, the company has achieved 100 percent on-time delivery of parts with zero rejected, he says.

Big River sees no signs of slowing in the foreseeable future. In fact, management has plans to expand its cell with four Makino a51nx HMCs and additional pallet capacity. Extending the MMC2 to cover the length of the shop will also help grow capacity.

The goal is to increase the company’s productivity and customer base through technology, Mr. Roehm says. “We want to buy the best equipment and train the best people in order to execute our philosophy of producing excellent products in a timely fashion.”

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More