Cutting The Learning Curve

A grinding shop in western Pennsylvania uses self-teaching CNCs to boost productivity.

Share

During the past 20 years, the ground rules of the metalworking game have undergone significant changes. American manufacturers who once enjoyed considerable insulation from overseas competitors increasingly have been forced to develop new strategies to offset the impact of a global labor market. The efficiencies gleaned from new technologies in hardware—while substantial—are not sufficient to address the full dimension of this challenge. Because industrial education programs are not as well established in the United States as in some other nations, American machine shops must shoulder higher development costs for new employees who typically are learning their elementary skills on the job.

For this reason, a crucial element in the competitive profiles of successful American shops is the ability to complete greater amounts of work using people who possess relatively modest skill levels. While CNC machinery has been the norm in milling, turning and EDM operations for some time, widespread use of CNC grinding machines is a comparatively recent development for many shops. Judging by the experience of a company with ambitious plans for future growth, however, the era of manually controlled grinding machines is rapidly coming to an end.

When he established Aggressive Grinding Service, Inc. (Latrobe, Pennsylvania) in 1988, company president Lester Sutton recalls a substantially different environment than the one existing today. “When we first established the business, the standard lead time for part deliveries was approximately 6 weeks,” he says. “Today, we deliver about 70 percent of our jobs within 24 hours.” This significant change reflects a business environment in which delivery time has become a dominant factor. To meet the demands of today’s markets, CNC has become a necessity for grinding operations.

Besides delivery time, pricing pressure is another important factor. “We’re doing some jobs today at prices of only about half the amount that we used to receive,” says Mr. Sutton. Approximately 50 percent of the company’s current business consists of manufacturing drill blanks and prepping other products for the cutting tool industry. In 1999, however, excess capacity among the company’s customers created a sharp and substantial reduction in the company’s business. “This overcapacity allowed the cutting tool firms to begin producing all or most of their blanks in-house,” Mr. Sutton says.

Faced with these difficult conditions, it was tempting to conclude that closing or selling the business was the only alternative. Instead, however, Mr. Sutton decided that the lower prices of competitors indicated that his company needed to develop a leaner operation. With the able assistance of his wife, Karen, who manages the firm’s business office, Mr. Sutton began preparing the company to respond to the pressures of a global economy.

Pursuant to this goal, the company has invested more money in capital equipment during the past 3 years than ever before. This equipment upgrade comprises a total of 15 CNC machines. Despite the fact that the overall cutting tool market has not grown substantially during this period, the company’s business has improved steadily since the 1999 doldrums. This is a strong indication that the company’s investments are already paying significant dividends.

With solid earnings recorded in 2002, Mr. Sutton is aiming for 33 percent sales growth in 2003. To meet this increased demand, the company is currently preparing to relocate to a new and larger facility in Latrobe. A key aspect of this forward-looking scenario is the company’s recent acquisition of CNC grinding centers that enable operators to teach themselves. Although Aggressive Grinding’s transition is still in progress, Mr. Sutton says, “Our goal is to make this company a world-class grinding operation.”

Self-Training CNCs

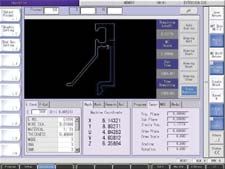

Within the past 3 years, the company purchased eight CNC grinding centers manufactured by Tru Tech Systems (Mt. Clemens, Michigan), and four more machines were ordered in May. Some of these machines are standard OD grinders and some are three-axis OD grinders. For greater efficiency in maintaining wheel geometry and surfaces, the machines incorporate on-board dressing attachments. Correct dressing routines are specified by the CNC that runs Tru Tech’s Pick-N-Place software. This user-friendly program combines the functions of conventional training and maintenance manuals. The program employs a talking British character that prompts the operator through each stage of setup, production and machine maintenance. It also incorporates on-screen calculators for trigonometry and radius problems.

Provided that new employees have some basic computer and math skills, they can be trained to operate these grinders in a matter of hours. This represents an important advantage for a shop that aims to be globally competitive. “Typically, each of our trained operators is operating two or three machines at once,” says Mr. Sutton. While previous experience in metalworking is certainly desirable for new shop personnel, it’s not required. For example, one of the shop’s current employees, who learned to operate this system in only a day, formerly worked in an auto parts store.

Located approximately 40 miles east of Pittsburgh, Latrobe is a relatively small town with surprisingly deep roots in manufacturing. Perhaps because of Pittsburgh’s dominant influence as an industrial center, western Pennsylvania is distinguished by having several small towns with similar traditions. As a result, Mr. Sutton has been quite successful in finding conscientious, young people who are enthusiastic about learning the trade. The company also works with a local technical school to recruit new employees.

Despite having the tools to train operators more rapidly, Aggressive Grinding continues to provide new employees with traditional training that begins with experience on manual grinders. This provides employees with an intimate knowledge of the grinding process and familiarizes them with various types of grinding machines, wheels, dressing procedures and workholding. The company has also developed an eight-step checklist to guide employees through the entire manufacturing and inspection process. Mr. Sutton believes that these practices represent key factors in his firm’s success.

Changes In Attitudes

The willingness to embrace constant and rapid change is the distinguishing trait of today’s successful metalworking professional. Accepting this reality, Mr. Sutton says, “I always tell my employees that we never get a good job that we will keep.” To acknowledge this perpetual fluidity in client needs and competitive relationships represents a significant departure from the mentality that once prevailed in many machine shops. According to conventional wisdom, a company’s competitive advantage is thought to consist principally in terms of proprietary information about processes and techniques.

But Mr. Sutton doesn’t believe that this model addresses the realities of the market that his company serves. “I believe that partnering with our customers is the key to our survival,” he says. “We willingly share our process information with customers, even when this might enable them to eliminate some work that would otherwise be subcontracted to our company.” Besides solidifying the company’s customer relationships, Mr. Sutton believes that sharing of best practices enables domestic manufacturers to preserve jobs in the United States. Aggressive Grinding is proving that this strategy is highly effective, because it currently obtains all of its business via customer referrals and without the need for a sales force.

The company’s experience confirms the value of two important keys to success in today’s global economy. The first key is the need to continually raise the performance bar for equipment, processes and personnel. This strategy of continuous improvement recognizes that worldwide proliferation of knowledge and technology is bound to frustrate attempts to covet temporary advantages. The second key is the need to become an invaluable and readily available resource for customers, recognizing that the links between partnering efforts and new business may not necessarily be obvious. In the metalworking field today, being proactive means anticipating that markets inevitably will favor the best-organized, most efficient and best-prepared companies.

Related Content

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)