When to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

Share

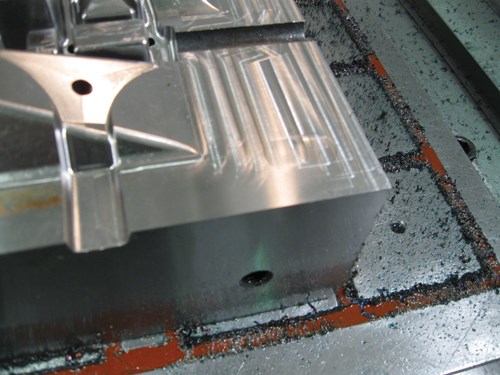

For mold and die makers, the idea of producing complex parts through high speed machining as an alternative to EDM is nothing new.

Or is it?

At D1 Mold & Tool, a maker of die cast dies in Daleville, Indiana, the application of fast, light milling passes on high speed machining centers keeps on becoming new. Capability improvements push back the barriers of this machining. It has happened again and again.

For example, cutting tools keep changing. The coatings used on small-diameter milling tools get progressively better. The shop routinely experiments with new tools, and routinely increases its cutting parameters based on the performance improvements it discovers.

CAD/CAM capabilities are also getting better. The latest version of Mastercam that the shop now uses includes toolholder interference modeling. This might seem like a small improvement, but it has allowed this shop to apply short, rigid tools significantly more aggressively when milling deep into the cavities of hard steel dies.

Ongoing improvements resulting from changes such as these affect the calculus of high speed machining. For this shop, an appropriate job for high speed machining typically is a die that can be produced within an 8-hour unattended shift on the machining center, as opposed to the 10 or more hours that might be required to mill an electrode and burn the part through EDM. With the shop’s milling performance continuing to improve, the range of jobs that can be completed within this window of reasonable cycle time continues to grow—and the threshold of the shop’s thinking about when to use high speed machining therefore keeps on changing.

Small Tools

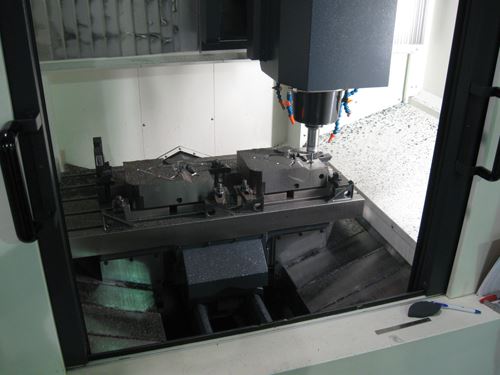

Tony Dungan has been incrementally increasing the use of high speed milling as an alternative to EDM since he founded the shop in 2002. D1 began with a ram EDM machine and a machining center for milling graphite electrodes. Now, the most heavily used machine in the shop is a Makino S56 VMC with a 20,000-rpm spindle. This VMC routinely cuts hard metal dies through the night, milling complex features with tools as small as 0.020 inch in diameter. Two YCM machining centers with spindle speeds of 15,000 and 12,000 rpm are used just about as extensively, often running through the night using small tooling themselves.

The size of the cutting tools is the reason why speed is essential. In place of making the part using an EDM electrode, small-stepover milling passes produce the part’s intricate details and smooth surfaces. The toolpath stepovers are so small that the number of discrete passes is very large. With so many passes, the machining cycle is long even when the feed rate is fast. Thus, only a very high feed rate—made possible by a high spindle speed—makes it possible to machine a complex shape quickly enough that the nighttime hours (plus a few daytime hours) are sufficient to complete the part.

Mr. Dungan points to other process components that he also sees as essential to the shop’s use of small tools. One of these is shrink-fit toolholding—the most reliable way he sees for achieving stable, low-runout clamping of the tool. Another is laser tool measurement. All of the metal-cutting machining centers at D1 have Blum laser tool setting devices, allowing each machine to quickly measure tool length and diameter offsets while the tool runs at its full spindle speed.

Mr. Dungan points out that this laser tool inspection is useful for standard-size tools, too—particularly when it comes to milling smooth, flat surfaces. By regularly updating a tool’s length offset using the laser, the machine can adapt to small changes resulting from temperature differences in the shop. In this way, the cycle can automatically avoid leaving even a small step between milling passes that would have to be ground away later by hand.

Toolholder Advantage

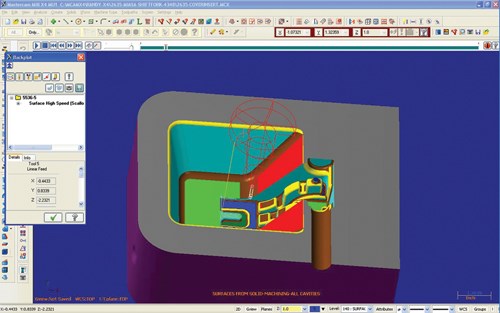

Another resource useful for small tools is Mastercam’s toolholder interference feature, says Randy Walker, the shop’s NC programmer.

D1 uses this CAM software to generate all of the machining centers’ HSM tool paths. In high speed machining, a constant Z-level machining strategy is applied to vertical features, and raster cutting is applied to horizontal features—with Mr. Walker judging between these two strategies for sloping features that fall between horizontal and vertical.

Past versions of this software have accounted for just the dimensions of the tool itself. This required Mr. Walker to be conservative with how far he allowed short tools to reach into a cavity of the part. The toolholder might interfere, hitting the part as the tool proceeds deeper. But now the software tells him precisely where this interference will occur. As a result, short tools can be used confidently, as deep into the part as they will go. Watching the toolholder interference on the screen today, Mr. Walker says he is sometimes surprised by a short tool cutting all along a sloping surface of the part without the toolholder getting in the way. In these situations in the past, he would always have switched to a longer tool.

Avoiding that switch is significant, because the shorter tools often provide needed rigidity. Sticking with a short cutting tool rather than using a long one means that the machine can mill that much more aggressively. It also means the process is less subject to the tool deflection that can prevent deep, critical features from being machined accurately through milling. For both of these reasons, this one feature of the CAM software has contributed to the shop being able to use high speed machining for jobs that might have been assigned to EDM as recently as just a year ago.

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More