Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776 US

877-668-4262 | 978-443-5388

sales@methodsmachine.com

methodsmachine.com

IS THIS YOUR COMPANY?

Video Gallery

Introducing Multiaxis Intelligence - Your Personal Digital Twin #ai #manufacturing #cncmachining

Multiaxis Intelligence is a joint solution from Methods and Multiaxis, LLC will create a powerful, personalized manufacturing AI ...

Kinematic Calibration on the 5-axis OKK HM-X6000 #5axiscnc #machinetools #cncmachine

An example of kinematic calibration on the OKK HM-X6000, a 5-axis horizontal machining center. Methods is the exclusive ...

Who is Methods Machine Tools? Importer, Solution Provider, and Engineering #cnc #machinetools

We combine best-in-class precision machine tools, CNC automation solutions, engineering expertise, and lifetime service.

FANUC RoboDrill Plus K MAX - from Methods Machine Tools #cncautomation #fanuc #5axis #5axiscnc

NEW! At IMTS 2024, Methods introduced the FANUC RoboDrill Plus K MAX. This new fully-integrated, 5-axis automation solution ...

As Seen On Modern Machine Shop

Methods Machine Tools, Inc. Supplies the Following Products

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Angle & Sub Plates

- Arbors, Expandable Workholding

- Assembly & Testing Automation

- Automated for Material Joining

- Bed-Type Milling

- Boring

- CAD/CAM Software

- Chuck Jaws & Collets

- Chucks, Collet Type (for Workholding)

- Chucks, Precision

- Chucks, Self-Contained

- CNC Drilling & Tapping

- CNC Software, Stand-alone

- CNC Turn/Mill Machines

- CNC Units

- Comparators, Optical & Other

- Composites

- Coordinate Measuring Machines (CMMs)

- Deburring Equipment

- Deburring Machines

- Die & Mold Components

- Die Handling Equipment

- Digitizing/Scanning Systems

- Dividing & Indexing Heads

- Drilling Heads/Attachments

- EDM Filtration Equipment & Supplies

- EDM Tooling

- Electrode Materials, EDM Wire & Supplies

- Engineering Analysis & Simulation

- for Composite Parts

- for Metal Parts

- Graphite Milling

- Horizontal CNC Turning

- Horizontal, Five-Axis

- Horizontal, Up to Four-Axis

- Hybrid AM Machines

- Indexers & Rotary Tables

- Inverted Vertical CNC Turning

- Jig Boring

- Laser Accessories & Supplies

- Laser Cutting Systems

- Laser Marking Systems

- Laser Measurement Systems

- Lasers, CO2

- Lasers, Nd: YAG, Continuous Wave

- Lasers, Nd: YAG, Pulsed

- Leasing & Financing

- Machining Flex Lines

- Machining Services

- Maintenance & Repair

- Material Forming & Fabricating Automation

- Material Removal Automation

- Metal

- Milling Heads/Attachments

- Multi-Spindle Drilling Machines

- Nano & Micro Machining

- NC Program Optimization

- NC Verification

- Non-Servo Electric Motors (Including Spindles, Drive Units & Power Feeds)

- Pallet Systems

- Plastic-Working Equipment

- Post Processors, Stand-Alone

- Press Automation Devices

- Ram Type (Die-Sinking) CNC EDM

- Ram Type (Die-Sinking) Manual EDM

- Retrofitting, Rebuilding, Remanufacturing Services

- Robot Controllers

- Robot Tooling/Grippers

- Robots, Industrial

- Roundness Measuring Equipment

- Small Hole EDM

- Software, Other Manufacturing

- Spindles

- Surface Finish Measuring Equipment

- Tap Drivers & Attachments

- Tool Condition Monitoring Systems

- Tool Presetters

- Tool Presetting Equipment

- Toolholders

- Tooling Systems, Modular and/or Quick-Change

- Training

- Twin-Spindle/Twin-Turret Turning

- Universal

- Universal Milling Machines

- Vertical CNC Turning Centers

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

- Vises & Vise Jaws

- Vision Systems

- Wire Type EDM

- Workholding, Custom

Trade Names Offered by Methods Machine Tools, Inc.

- Kiwa

- FANUC

- Weiler

- OKK

- Yasda

- Nakamura-Tome

Editorial, News, and Products

-

Collaboration is the Focus for Methods Machine Tools

Methods Machine Tool focuses on collaboration and services at its IMTS 2024 booth.

-

Methods Machine Tools Promotes Vice President of Engineering and Development

Methods Machine Tools Inc. has promoted James Van Buskirk to the role of vice president of engineering and development.

-

Methods Machine Tools Promotes New SVP of Sales

David Chesnutt assumes responsibility for all national product sales through Methods’ direct offices and dealer network.

-

Methods Multitasking Machine Reduces Cycle Times

Methods Machine Tools Inc. introduces Nakamura-Tome’s WY-100V two-turret, twin-spindle precision CNC multitasking lathe to the U.S. market.

-

Methods Machine Tools Inc. Appoints New CEO

Richard Alton will assume responsibility of all operating functions of Methods Machine Tools Inc. across its nine direct offices throughout the U.S.

-

Methods Machine Tools to Host Open House Event

Methods Machine Fest will provide attendees with an up-close view of Methods’ entire portfolio of three- and five-axis CNC platforms, EDMs, multitasking lathes, automated and integrated solutions, services and support.

-

Methods Machine Tools Renews Strategic Partnership With Yasda

Methods is the single importer, distributor and service provider of Yasda Precision Tools K.K.’s portfolio of precision machining centers in the U.S.

-

How Automation Boosts Output in High-Mix Environments

Machine shops of almost any size and production mix can automate machining operations. The key is selecting the right technology to fit the need and working with a reliable supplier to deliver planned performance. The result will be more opportunities for your shop to increase capacity, revenue, and profit.

-

Automation Solutions, Multitasking Machines Take Center Stage at Machine Fest 2023

Methods Machine Tools' Chicago-area Machine Fest saw over 15 live demos and more than 20 industry vendors over its two days, with a noticeable presence of automation solutions and multitasking machines.

-

Methods Machine Tools to Host Open House Event in Illinois

Machine Fest takes place from March 8-9, 2023 at the company’s Gilberts, Illinois, location.

-

United Grinding Expands Distribution Network in Mexico

Intermaq will represent United Grinding’s full line of equipment and expand the precision CNC grinding market in Mexico.

-

Methods Machine Tool Hires New General Manager

William Keim leads Methods’ sales, services and operations throughout Texas and Louisiana.

-

Methods Machine Tools Opens New Location in Southern California

The larger facility is designed to provide customers with an improved onsite experience to learn and discuss comprehensive manufacturing solutions.

-

Methods Machine Tools Becomes Sole U.S. Partner of OKK

Methods began selling OKK in the U.S. in 2019 and recently expanded its coverage of OKK into the U.S. Southeast and Wisconsin.

-

Semicollaborative System Engineered for Lathe Automation

Methods Machine Tools showcases the Turn-Assist 200i and 270i from Robojob for Nakamura-Tome turning centers.

-

Weiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

-

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

-

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

-

Nakamura-Tome SC-100X2 Optimized for Complex Part Production

Nakamura-Tome SC-100X2 turn-mill is designed to reduce cycle times and cost per piece with superimposed machining.

-

Methods Launches Twin-Turret Multitasking Machine

Operators can use the Nakamura-Tome SC-100X2’s twin turrets for superimposed machining or twin-spindle machining, achieving high speed and precision with both.

-

Automation Cell Outperforms CNC Machines Fourfold

An automated turnkey machining cell simplified one Utahan manufacturer’s part handling and halved its cycle times.

-

Methods Machine Tools Partners with Lathe Manufacturer Weiler

The company now offers V-series and E-series lathes from German manufacturer Weiler to its customers in North America.

-

Methods Partners With Maruka, Expands Territory

Methods Machine Tools Inc. has signed an agreement Maruka USA that enables the company to expand into N.D., S.D., Minn., Iowa and Neb. The two companies have worked together since 2013.

-

Methods Machine Tools Set to Acquire Koch Machine Tool

Methods notes that after finalizing the agreement, machine shops throughout Texas will be able to use its applications and automation teams to solve complex machining challenges.

-

Moving to Horizontal Machining Cuts Shop's Cycle Time by 50%

Adopting horizontal three-axis machining may require much consideration, but Alicat Scientific can attest to almost 50% cycle time reductions with a Kiwa horizontal machine.

-

Methods Machine Tools Adds New FANUC EDM Models

Methods Machine Tools Inc. added the next generation of the FANUC RoboCut series to its line of wire electrical discharge machining (EDM) products.

-

Methods Unveils New Automation Solutions

Methods Machine Tools has released a new automation package and other "bolt-on" automation solutions.

-

Methods Moves Chicago Technical Center to Gilberts

Methods Machine Tools has moved its Chicago Technical Center from Elgin, Illinois, to Gilberts, Illinois, saying the new facility will speed up repair and installation times.

-

Practical Approaches to Automating Five-Axis Machines

There are many approaches to automation in five-axis machining, and whether a shop uses robots or pallet changers, the benefits are often easier to realize than many believe.

-

Methods Machine Tools Releases VisionGauge OnLine Updates

Methods Machine Tools has released software enhancements for VisionGauge OnLine, especially benefitting VisionX’s Digital Optical Comparator 700 series.

-

Methods Expands VMC Automation with Revised JobShop Cell Pro

Methods Machine Tools has revamped its JobShop Cell with a new Pro model that accommodates multiple infeed and outfeed options for high-mix, medium-volume machining.

-

Methods Optimizes Three-Axis MV 1600H for Large Workpieces

Methods Machining tools has released its MV 1600H three-axis vertical machining center, which it says can quickly and precisely machine large workpieces.

-

Multi-Pallet Machines Help Shop Produce Ventilator Components

NRL & Associates’ business plan relies on using multi-pallet machines for unattended machining, so when two of its customers increased production of ventilators, the shop quickly brought in a new multi-pallet machine and automation system to meet the demand.

-

Methods MB 450U Performs Simultaneous Five-Axis Machining

The MB 450U bridge-type machining center from Methods Machine Tools performs simultaneous five-axis work thanks to its FANUC control.

-

Nakamura-Tome JX-250 Multitasking Turn-Mill Provides Large Work Area

The Nakamura-Tome JX-250 multitasking turning center from Methods Machine Tools provides a large work area for milling and turning of complex parts.

-

Shop Reins in Lead Times with Compact HMCs

Alicat Science experienced a surge in business that drove lead times to 28 days. KMH300A horizontal machining centers reduced lead times to five days and gave the shop the capacity for subsequent business growth.

-

Methods Machine Tools Represents OKK Corp. in North America

“Methods' established distribution organization, vast network of technology centers and dealers, and first-class applications expertise will help increase OKK presence in North America,” says OKK.

-

Methods Machine Tools Appoints President, CEO

Mark Wright is said to have a global outlook in strategic planning, growth initiatives, and sales channel programs and development.

-

June 2019 Product Spotlight: Electrical Discharge Machining (EDM)

This month’s Modern Equipment Review Spotlight focuses on different types of electrical discharge machining equipment.

-

Methods Machine Tools Opens Climate-Controlled Precision Test Cut Facility

The new Precision Center will enable manufacturers to arrive at accurate and efficient machining solutions for complex components, saving them trial and error in their operations.

-

Methods Seeks the Perfect Machining Environment

With its new Precision Center, Methods Machine Tools is locking down environmental variables that could impact machining processes. Why? So North American manufacturers will no longer need to send parts, tooling and material to Japan or somewhere else to have intricate, sensitive or challenging test cuts performed.

-

The Case for 3D-Printed Workholding: Collapsing Costs and Lead Times

When Precision Metal Products purchased its first 3D printer last year, the company hoped to collapse both tooling costs and lead times. But the technology’s impact is reaching core business operations, enabling the shop to focus on higher-margin, lower-volume production.

-

Methods Commits to Medical with New Tech Center

The company says the facility is well-positioned to fill healthy demand for CNC machining equipment, service and support among medical manufacturers in the southern United States.

-

News of Note: October 2018

The NTMA appoints a new president, Röhm acquires Master WorkHolding, Renishaw opens new demo center and more industry news.

-

10 Ways to Think Differently about Robotic Automation

Take another look: A lot is happening in and around robotic automation. What robots might mean for machining and manufacturing is getting ready to change.

-

Methods Machine Tools Partners with Niigata

Methods Machine Tools Inc. has entered into an agreement to represent Niigata Machine Techno USA throughout the United States, Canada and Mexico.

-

Varied Demos Push Robots Beyond Just Part Handling

Pre- and post-machining automation can help coordinate product flow, increase quality and relieve operator stress.

-

Entry-Level EDM Features Break-Through Detection

IMTS 2018: Methods Machine Tools will display Ocean Technologies’ River 300 EDM drill machine.

-

Methods Machine Tools Makes Two Leadership Appointments

Methods Machine Tools has appointed Jerry Rex as company president and CEO and Dale Hedberg as vice president of operations.

-

Multitasking Turning Center Accurately Machines Hard Materials

IMTS 2018: Methods Machine Tools will be featuring the Nakamura-Tome SC-300IIMYB multitasking turning center designed for accurately machining difficult, high-hardness materials.

-

Methods Machine Tools Celebrates 60th Anniversary

The company has grown from three employees and a few refurbished machines to over 350 employees, eight North American facilities and tens of thousands of machines sold.

-

Using Data to Do Better in Manufacturing

Although the Smart Manufacturing Experience 2018 event in Boston may not have provided a simple, clear definition of “smart manufacturing,” it did provide a broad experience of what smart manufacturing can be like.

-

Video: High Production Rate on VMCs Using Robotic Automation

This “Twin Cell” system uses one robot to deliver work into the cell and another robot to load both of the machines. The choice to remove machine doors enables faster load/unload time between machining cycles.

-

Automation Events Highlight Deburring

This tedious, costly and complex operation was one focus of two complementary, same-day events that covered virtually every aspect of industrial robotic automation.

-

A Stitch in Time—A New Core Retention Function for Wire EDM

When running a wire EDM such as the FANUC RoboCut C800iB, an automatic routine in the CNC program adds a "stitch" at a few strategically placed locations around the periphery of the core. By holding the cores in place until the entire job is finished, multi-workpiece cutting processes are able to run in an extended, unmanned mode.

-

Methods Machine Tools Announces New President

Jerry Rex, formerly the company’s COO, was picked to replace Bryon Deysher as president of the firm.

-

Manufacturing News of Note: May 2017

AME opens an engineering training department, Kapp Niles launches a new metrology business and more industry news.

-

Automation Advances at FANUC 2017 Private Show

Updates unveiled at the company’s annual event promote higher-volume production, easier programming and better monitoring capability across product lines.

-

Methods Machine Tools Launches New Automation, Integration Center

The Charlotte, North Carolina, facility is slated to open this spring.

-

Adding Context to Advanced Milling

For all its focus on machines, cutters, parameters and tool paths, an expo hosted by Methods Machine Tools demonstrated that competitive hard milling increasingly requires looking beyond the workzone and even beyond traditional machining.

-

Five-Axis Machine’s Gantry, U-Shaped Base, Column Increase Rigidity

Methods Machine Tools has expanded its Feeler line to include the gantry-style U-800 five-axis machining center, designed for versatile high-precision machining of large, heavy parts.

-

Robots Armed for More Than Machine Tending

Although they’re more eager than ever to embrace robotic arms, manufacturers that don’t look beyond the machine tool risk missing out on opportunities to automate processes like deburring, cleaning and inspection.

-

Rigid Turning Center’s Y Axis Travel Extends to 150 mm

Methods Machine Tools has expanded its Feeler FT-series high performance CNC turning centers with the FT-250SY.

-

Vertical Jig, Boring, Drilling Machine Machines Five Sides of Workpiece

Methods Machine Tools offers the Yasda YBM Vi40 five-axis vertical CNC jig, boring and drilling machine designed for hard milling applications and complex dies, molds and components in the aerospace, defense, automotive, medical and electronics industries.

-

Methods Machine Tools Subsidiary Opens Seven AM Labs

The labs are located in existing Methods technology centers.

-

Automotive Manufacturer Grows through Automation

Gil-Mar Manufacturing met growing application demands on their average machines by partnering with Methods Machine Tools to automate and integrate them.

-

Direct Metal 3D Printer for Titanium, Stainless, Nickel Super Alloy

Methods 3D, a subsidiary of Methods Machine Tools, will be showcasing the ProX DMP 320, part of the company’s growing line of direct metal 3D printers from 3D Systems.

-

June 2016 Product Spotlight Slideshow: EDM

This month’s Modern Equipment Review Spotlight focuses on electric discharge machines, or EDMs.

-

Wire EDM’s Thermal Compensation Maintains Positioning Accuracy

Methods Machine Tools introduces the FANUC RoboCut α-CiB wire EDM series which includes the C400iB, C600iB and the larger C800iB.

-

Manufacturing News of Note

Jerry Rex has been appointed COO of Methods Machine Tools Inc., MakeTime receives $8 million in funding and other recent industry news.

-

Multitasking Offers Medical Benefits

This shop uses a bar-fed turn-mill with a B-axis milling spindle and custom workholding strategies to more competitively machine components complete for low-margin medical devices.

-

Dedicated Multitasking Machine Is the Answer for a Complex Medical Part

Precision Swiss Products Inc. needed a machine that could accommodate a dedicated job with a unique material/application. A Nakamura AS-200 multitasking center with chip-management system from Methods Machine Tools produced enabled production of high-quality parts in a short lead time.

-

A Swiss-Type Turning Point

The lessons this shop learned after purchasing its first Swiss-type turning center nearly two decades ago are now being applied to larger multi-spindle and multi-turret lathes for bigger and more complex parts.

-

December 2015 Product Spotlight Slideshow: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on machining centers.

-

Methods Event Debuts Additive Manufacturing Offerings

The company’s investments around its partnership with 3D Systems will help smaller manufacturers succeed with additive, Methods Machine Tools says.

-

Twin-Spindle Turning Center Offers Large Machining Area

Methods Machine Tools introduces the Nakamura-Tome NTRX-300, a multitasking turning center capable of complete part machining in one operation with a built-in automated load/unload system and operator recognition management software.

-

Video: Robot Flipping System for Turning

This video demonstrates how robot flipping station can serve the same purpose as a subspindle on a one-spindle multitasking center.

-

Micromachining Center for Die/Mold Applications

Available from Methods Machine Tools, the Yasda YMC 430 Ver. II micromachining center is designed for precise manufacturing and high-quality surface finishes required on small, complex features in components, dies and molds for applications in the medical and semiconductor industries.

-

March 2015 Product Spotlight Slideshow: Machining Centers

Click through this slideshow for HMCs, VMCs, multitasking centers and more.

-

Five-Axis Jig Boring and Milling Machine for Die-Mold

Available from Methods Machine Tools, the Yasda YBM Vi40 five-axis vertical jig boring and milling machine is intended for high-accuracy hard milling of complex dies, molds and components.

-

A Hollow-Access Unit for Wire EDM

By simultaneously rotating and tilting the workpiece, this rotary tilt/turn hollow-access device from Hirschmann enables the EDM wire to cut complex openings that may have different paths at the top and bottom of the opening.

-

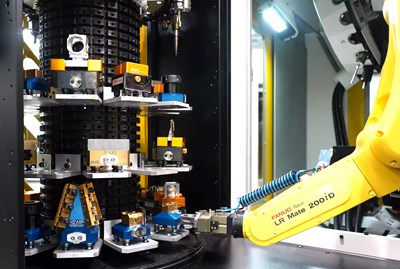

Robot-Tended VMC Cell Changes Multiple Workpieces Simultaneously

Available from Methods Machine Tools, the Twin RoboDrill JobShop Cell features two FANUC D21 RoboDrill vertical machining centers serviced by a single articulating FANUC LR Mate 200iD robot.

-

Five-Axis Machining Center for OEMs, Job Shops

Available from Methods Machine Tools, the Methods-Yasda PX-30i is a five-axis high-precision automated vertical machining center designed to meet OEM and job shop requirements.

-

Multi-Pallet HMCs Reduce Setup Time

Incorporating Kiwa horizontal machining centers from Methods Machine Tools helped Baum Precision Machining Inc. reduce setup time and improve productivity.

-

More Accurate Taper Cutting with Wire EDM

Cutting tall, steeply tapered surfaces with wire EDM often creates an overburn situation if the slope of the wire path changes from the top to the bottom of the cut. A feature called Volumetric Taper Compensation with four-axis overburn control compensates for this effect on FANUC wire EDM models from Methods Machine Tools Inc.

-

Automated Cell Enables Easier Operator Access

Methods Machine Tools offers the Lathe JobShop Cell, featuring its Nakamura-Tome AS-200 high-performance multitasking turning center with a single spindle and single turret in a compact, heavy duty machine.

-

Metal Storm Thunders through Sudbury

Methods Machine Tools Inc. hosted its annual open house and mini machine tool show at the company's headquarters in Sudbury, Massachusetts, last week. The highlights of this customer event are here.

-

Five-Axis Machining Center Features Adjustable Work Envelope

Available from Methods Machine Tools, the Yasda H40i high-precision five-axis machining center is designed for improved repeatability and accuracy, tighter tolerances, and shorter cycle times for aerospace, die/mold and automotive manufacturing.

-

Large Y-Axis VMC Enables Complete Machining in Single Setup

When Sarro Manufacturing couldn’t manufacture large, aluminum plates in one setup, it installed a Feeler VMP-1100S from Methods Machine Tools Inc. The VMC cut cycle time and spiked productivity.

-

EDM Series Minimizes Power Consumption

Available from Methods Machine Tools, the FANUC RoboCut α-CiA series C400iA and C600iA wire EDMs are capable of machining complex, detailed graphite electrodes ranging to 6" thick with a fine finish.

-

March 2014 Product Spotlight: Machining Centers

This slideshow features the machining centers we cover in the Modern Equipment Review Spotlight section in our March issue.

-

VMCs Equipped with High-Speed Processing Control

The FANUC D21 RoboDrill series of vertical machining centers from Methods Machine Tools features a FANUC 31iB control for FSSB high-speed processing.

-

Multitasking Turning Center Supports Off-Center Operations

The Nakamura-Tome AS-200 multitasking turning center available from Methods Machine Tools features a single spindle, single turret in a heavy-duty, compact machine.

-

Vertical Jig Boring-Milling Machine Enables High Accuracy

Available from Methods Machine Tools, the Yasda YBM 649V3 three-axis CNC vertical jig borer provides high-speed, precision boring and milling for high-accuracy mold, die and complex component manufacturing.

-

EDM Enables Remote Operation

Methods Machine Tools offers the FANUC RoboCut C600iA wire EDM, featuring the FANUC 31iWB control with a 15.1" LCD touchscreen.

-

Large Travel Size Increases Shop Productivity

By purchasing a Feeler bridge mill with a large travel size, Elite Tool increased productivity by reducing setups and doing more work in-house.

-

Multitasking Machine Increases Efficiency on Angular Features

The Nakamura-Tome NTJ-100 multitasking turn-mill center from Methods Machine Tool is designed for medical, aerospace and general job shop components applications.

-

Vertical Turning Lathe for Large, Heavy Parts

Methods Machine Tools’ high-performance Feeler FVT-600 vertical turning lathe is designed for machining large, heavy parts such as those used in the aerospace and power-generation industries.

-

Multitasking Machine Features Fast Cycle/Tool Change Time

Methods Machine Tools Inc.’s Nakamura-Tome NTJ-100 multitasking turn/mill center is well-suited for a range of production needs.

-

Straight Talk about Cutting Steep Tapers with Wire EDM

The RoboCut C400iA and two sizes of the larger C600iA wire EDM machines from Methods Machine Tools enable unusually steep tapers to be cut with the wire EDM process by positioning the workpiece with a rotary-tilt table.

-

Five-Axis Machining Center for High-Precision Applications

Methods Machine Tools’ Matsuura LX-160 two-pallet, five-axis VMC features 19.7" × 9.8" × 11.8" (500.38- × 248.92- × 299.72-mm) travels and a 46,000-rpm FANUC control.

-

Series of Digital Optical Comparators for Smaller Parts

Methods Machine Tools offers the 300 series of VisionGauge digital optical comparators developed by Visionx.

-

Simulate, Optimize, and Verify Turn-Mill G-Code

Methods Machine Tools offers CAMplete TruePath turn-mill software for the Nakamura-Tome line of turn-mill machines.

-

Multitasking Turning Center Offers High Speed, Rigidity

Methods Machine Tools’ Nakamura-Tome WT-150 II eight-axis, multitasking turning center features opposed twin-spindle, two-turret construction for increased speed and rigidity.

-

Improved Break-Out Detection for Small-Hole EDM

The Current EDM RT6050 features software and hardware upgrades that improve the ability to detect when the electrode breaks out of the bottom of a hole.

-

Automated VMC Fills Capacity Gap

A new Feeler VMC from Methods Machine Tools has not only met this manufacturer’s need for additional capacity, but also taken on more work than initially expected.

-

Tools Enable Automatic Part-to-CAD Verification

Methods Machine Tools offers the VisionGauge digital optical comparator system and its new CAD Auto-Align and Auto Pass/Fail software tools, developed by VisionX Inc., to enable users to automatically compare a part to its CAD data in real-time.

-

Multitasking Center Features High Speed, Rigidity

Methods Machine Tools’ Nakamura-Tome WT-150 II eight-axis, multitasking turning center features opposed twin-spindle, two-turret construction for increased speed and rigidity.

-

Shop Finds Perfect Fit in New VMC

A Feeler VMC from Methods Machine Tools helped this shop produce larger parts more efficiently and accurately.

-

Sizing up the Digital Optical Comparator

A digital optical comparator uses a CAD file instead of a template or overlay film. More importantly, the digital comparator not only measures dimensions, but it also actively compares the measurements with nominal values, thus making it truly a gage for accepting or rejecting a part.

-

Milling Lathes and Turning Centers

Methods Machine Tools’ Feeler milling lathes and turning centers include the HT, FTC and FT series.

-

The Buzz about the B Axis

The rotating milling head is a defining feature on a turn-mill machine designed for efficient production of complex parts in low volumes.

-

Complete Turn-Mill Software for Multitasking Machines

Methods Machine Tools offers CAMplete Truepath turn-mill software on Nakamura-Tome multitasking turning centers.

-

Spark Control Pushes Wire EDM Boundaries

Precisely controlling and monitoring each individual spark enables this wire EDM machine to cut hardened, high-temperature alloys with high precision.

-

A New Milling 101: What Customers Demand

Part 5. For W Machine Works in San Fernando, a custom variation of the WIDIA-Hanita VariMILL II solid end mill proved especially effective in roughing and semi-finishing applications in stainless steels, high-temp alloys, nickel- and carbon-based alloys, and titanium.

-

Job Shop Uses 3D Wire Bending and CNC Machining To Find Its Niche

Marshall Manufacturing melds CNC machining and 3D bending to create intricate medical components from small-diameter barstock and tubing. Customer needs spurred the shop to carve out what has become a successful medical-manufacturing niche.

-

Five-Axis Automation for Medical Machining

Methods Machine Tools’ RoboDrill Med Cell is a complete pre-engineered, fully integrated production machining cell that automates loading and unloading of medical device parts.

-

Digital Optical Comparator

Methods Machine Tools is the exclusive North American distributor of VisionGauge digital optical comparators, developed by VISIONx.

-

Twin ATC, B-Axis, Multitasking Turn-Mill

Methods Machine Tools’ Nakamura-Tome Super NTMX multitasking turn-mill machining center features dual, 24-tool ATC magazines.

-

The Automation Inspiration

Although automated manufacturing cells typically consist of standard products such as CNC machine tools, robots, pallets and cell control software, almost all of these systems rely on inventive concepts developed for the particular application. These "good ideas" often account for the outstanding productivity and flexibility of these systems. This article looks at several of the "good ideas" that characterize a cell comprised of seven wire EDM units and a robot on a rail transfer unit.

-

Twin ATC, B-Axis Multitasking System

Methods Machine Tools’ Nakamura-Tome Super NTMX multitasking turn-mill offers dual 24-tool ATC magazines. Full five-axis milling capability via a Fanuc 31iA5 control is said to provide high precision and accuracy for manufacturing complex contoured components in large or small volumes for the medical, aerospace and similar industries.

-

Looking At 30-Tapers In A New Light

The six 30-taper machine tools in one Northeastern shop are used for more than just drilling holes and performing secondary operations. The small-footprint equipment is also used to machine parts complete from titanium and other challenging materials.

-

Automation Cell Maximizes Job Shop Flexibility

Methods Machine Tools’ JobShop Cell is designed for job shops with small to medium lot sizes. The fully integrated production cell combines the drilling, tapping and milling capability of a RoboDrill VMC with a fully interfaced Fanuc six-axis robot for automated loading and unloading.

-

Horizontal Leap Helps Shop Change And Grow

Migrating from short-run jobs and prototyping to tackling complex defense compartment components during the past few decades has kept business humming at Proteus Manufacturing. However, increased business led to new production challenges. With a single Kiwa HMC from Methods Machine Tools that can perform the work of three of the shop’s other machines, Proteus has realized substantial cycle time savings and incorporated “lights-out” operations.

-

Shop Reduces Setup Time With Multi-Pallet Machines

Automated, lights-out production has enabled this manufacturer to take on a large number of low-volume jobs for various industries. With a wide variety of work, minimizing setup times is key to the shop’s success. Multi-pallet, four- and five-axis Matsuura machines supplied by Methods Machine Tools have enabled the shop to not only keep setup times low, but also meet customer demand for nearly error-free production runs.

-

Robotic Cell Locks In Time, Cost Savings

Having implemented robotic systems in the sheet metal side of its business, this Nevada-based shop wanted to obtain similar automation systems for its CNC machining operations. The Fanuc JobShop Cell from Methods Machine Tools has reduced both costs and cycle times on one of the shop’s most important jobs.

-

Sharing The Big Picture

The theme of visibility in manufacturing finds expression in numerous ways at this shop. One of the most conspicuous is the use of plasma displays in strategic areas to summarize the company’s performance as reported by its shop control/data-collection system.

-

Easy Does It

This shop specializing in small-scale parts says successfully machining tiny features into tiny workpieces is less about technology and more about technique.

-

Minimizing Part Setup With Five-Axis Technology

More unattended machining was one of the benefits of this shop's move from four-axis to five-axis machines.

-

B-Axis Turn/Mills Have Their Place

The additional rotary milling axis on these machines allows them to complete many types of complex parts in a single setup, but these machines have gained a reputation for being difficult to program. Today’s CAM software, however, eases the programming challenge significantly.

-

Small Possibilities

These shop founders focused on what they knew rather than what they had heard about economic conditions when they established their business in October 2000. Their knowledge included the conviction that wire EDM could become the shop’s primary machining process.

-

Tight Tolerances And Trial Runs

This contract shop is committed to difficult jobs. The shop often takes on a job without knowing how the part will be made.

-

The Long View On Short-Run Work

This shop doesn’t know what parts it will machine tomorrow, but it has a good idea who its customers will be well into the future.

-

EDM For The Long Run

To manufacture large quantities of similar parts, a Georgia machine shop has found that wire EDM is the ideal process.

-

Where Wire EDM Is A Workhorse

This shop finds the process practical, productive and predictable, an indispensable technology that supports all of its manufacturing capability.

-

For Unattended Machining, Attend To Pre-Process

Efficient use of labor is a primary goal of unattended machining. To successfully reduce process intervention, all of the manufacturing disciplines must participate. Accomplishing this requires detailed pre-process planning, which is the key to optimizing machine, material and manpower resources.

-

Methods' Revamped Lineup Features Advanced Technology

“Smart” machine tools. Spindles reaching 60,000 rpm. Affordable robots for load/unload.

-

Why We Couldn't Live Without EDM

A shop discusses some of the ways that EDM solves problems and creates opportunities in parts manufacturing. Wire EDM, ram EDM, and small-hole EDM all play a key role.