A Hollow-Access Unit for Wire EDM

By simultaneously rotating and tilting the workpiece, this rotary tilt/turn hollow-access device from Hirschmann enables the EDM wire to cut complex openings that may have different paths at the top and bottom of the opening.

Share

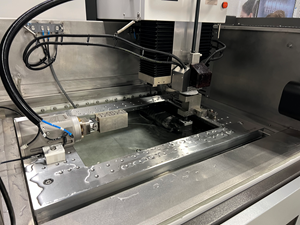

The “cutting tool” in wire EDM is the energized wire that passes into and through a workpiece as it travels from reel to reel. This is a remarkably flexible and capable cutting process because the path and orientation of the traveling wire is highly maneuverable under the multi-axis command of the CNC program. In addition, workholding systems for wire EDM can greatly enhance this flexibility and capability by adding coordinated positioning of the workpiece.

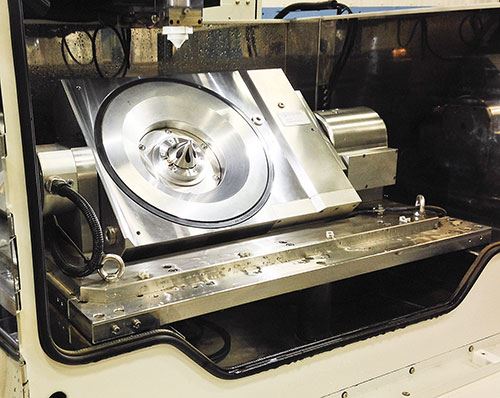

A prime example of this is the rotary tilt/turn hollow-access device from Hirschmann and marketed by Methods Machine Tools (Sudbury, Massachusetts) for its line of FANUC EDM units such as the RoboCut C600iA. This special tilt/turn table is available in different sizes. The model shown at IMTS and described here is the model JS FJRTH186RF-P-01.

“Rotary tilt/turn hollow-access” is a mouthful, but it is, in fact, a good way to characterize this device, which attaches to the tooling frame within the tank of the wire machine. It has two servo drives that are interfaced to the CNC. In operation, the unit enables the wire to cut complex openings that may have different paths at the top and bottom of the opening. The result is a “hollow” within a workpiece that may have a variably tapered and/or convoluted shape.

This complex hollowing is possible because the unit simultaneously rotates and tilts the workpiece. Unlike a tilting rotary table which typically rests on the surface of the worktable of a machining center, this unit is mounted from the sides and features a through-hole in which the workpiece is clamped. This arrangement enables the underside to remain open to the tank of the wire machine. In essence, the through-hole securely suspends the workpiece so that the travel of the wire is virtually unimpeded above and below for maximum access. The through-hole on this model is 5.86 inches (149 mm) in diameter and can handle a workpiece as heavy as 220 pounds (100 kg).

The three views of a sample workpiece on this page show the complexity of hollow openings that can be produced with this hollow-access device. This workpiece is 2.5 inches in diameter and 2.5 inches tall. Cutting such openings in this manner has advantages. This kind of tilt/turn table enables these complex contours to be machined while keeping the wire vertical. This means higher-tensile-strength wire can be used to obtain higher accuracy. Using higher-tensile-strength wire also makes wire threading more reliable for more efficient production runs. Because the upper and lower heads are always aligned, flushing with the dielectric water is improved, which results in faster cutting speeds and better surface finishes.

Methods Machine Tools pairs this hollow-access unit with the RoboCut C600iA because the size and capability of this wire machine are well-suited to the application. This machine has ample work tank dimensions to accommodate the overall length and width of the unit, which measures 32.17 by 9.25 inches (817 by 234 mm). The 16-inch stroke of the Z axis (wire height) on this machine provides clearance for the full range of the usable tilting capability of the unit as well.

The RoboCut’s FANUC 31iWB control unit has the processing speed and power for the multi-axis simultaneous control required to coordinate the added rotary and tilting axes in the hollow access unit. The nano interpolation capability of the CNC complements the ±5 arcseconds indexing accuracy of the hollow-access unit’s rotary and tilt servodrives. In addition, the highly reliable wire-threading system and precise wire-tension control of the RoboCut 600iA support cutting of complex hollow openings in workpieces made of demanding materials for medical or aerospace.

Related Content

Hybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Read MoreElectrical Discharge Machining in Ten Articles

This roundup of the top ten Electrical Discharge Machining articles on Modern Machine Shop covers the wide range of EDM topics.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreGF Machining Solutions Celebrates 70 Years of EDM Technology

GF Machining Solutions is celebrating the 70th anniversary of its discovery of EDM Technology.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More