Methods Machine Tools Subsidiary Opens Seven AM Labs

The labs are located in existing Methods technology centers.

Share

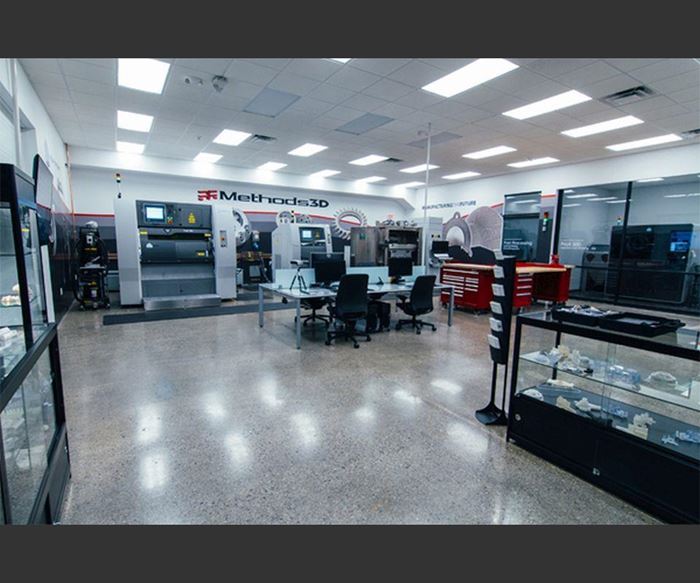

Methods 3D Inc., a newly-formed subsidiary of Methods Machine Tools Inc., has completed seven additive manufacturing laboratories located in various parts of the United States. Methods 3D has also added personnel to support its new infrastructure, and James Hanson, formerly director of corporate development with the parent company, has been appointed COO.

The new labs are located in each of Methods Machine Tools’ technology centers, including Sudbury, Massachusetts; Detroit, Michigan; Charlotte, North Carolina; Chicago, Illinois; Phoenix, Arizona; and San Francisco and Los Angeles, California. These additive manufacturing labs are outfitted with 18 printers including direct metal printing (DMP), select laser sintering (SLS), stereolithography (SLA) and multi-jet models running 14 different materials. A full complement of postprocessing equipment such as EDM, CNC machining, automation and inspection machines is also onsite.

“Our new additive labs are ideal for manufacturing professionals to consult our experts and explore ways to design and produce their components using the latest 3D technology integrated with conventional machining, automation and more,” Mr. Hanson says. “Engineers have been bringing their application challenges to us and we have been working with them to implement this technology into their manufacturing operations.”

Related Content

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

Digital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

-

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

_web.jpg;width=860)