Multi-Pallet HMCs Reduce Setup Time

Incorporating Kiwa horizontal machining centers from Methods Machine Tools helped Baum Precision Machining Inc. reduce setup time and improve productivity.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreAlthough Baum Precision Machining Inc. had reached a point at which growth and customer demands were straining production, the Pipersville, Pennsylvania, shop was skeptical of the prospect of moving into horizontal machining. Multi-pallets, tombstones and different orientations were considerations far from the shop’s familiar range of VMCs. However, during the Great Recession, the shop could no longer ignore its need to increase spindle uptime, and it ultimately decided to take the leap into HMCs. President Aaron Baum says, “I don’t think we could have survived or certainly thrived without our Kiwa HMCs.”

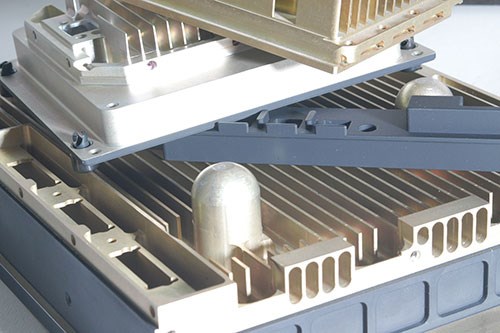

Founded in 1979, the 40-person shop now occupies an 18,000-square-foot facility and manufactures precise components from titanium 6AL-4V, aluminum, stainless steels and more, with part tolerances as tight as ±0.0001 inch for commercial aerospace and defense programs in addition to spine, trauma, orthopedic and extremity components in the medical sector.

“In general, customer requirements have become much tighter as the aero-space and medical markets mature and continuous improvements take place,” Mr. Baum says. “We are seeing more flow-down requirements from the primes and have also seen lead-time requirements shrink in recent years.”

According to Mr. Baum, the ability to turn around small-volume prototypes and qualification lots in a short timeframe is critical for Baum’s customers, and when the shop was unable to turn parts around fast enough for these shortened lead times, it lost some opportunities.

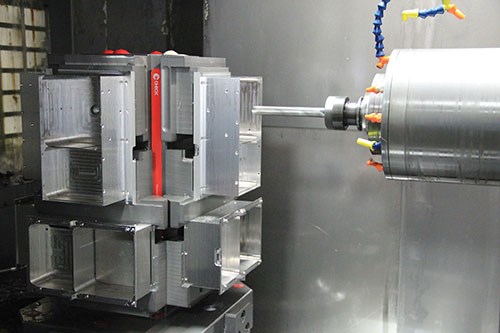

However, adding horizontal machining capability to its production process was a game changer. The shop now has three Kiwa-Japan HMCs in operation—one is an older two-pallet model, and the other two are Kiwa KH-45 six-pallet machines.

“We actually selected Kiwa before Methods Machine Tools Inc. (Sudbury, Massachusetts) represented the line because we liked the machine capabilities compared to others in the category,” Mr. Baum says.

The Kiwa machines accommodate a 400- or 500-mm pallet, giving them a slight advantage over other 400-mm horizontals, he says, and the pallet pool setup is designed in such a way that a relatively unskilled operator can load and run the machines after setup is complete. It is also easy to retrofit a two-pallet Kiwa to six or eight pallets in the field. In fact, Methods recently upgraded a two-pallet Kiwa that Baum purchased in 2008 into a six-pallet configuration. The machines were only down three days, Mr. Baum says, and the shop was able to make up the work in about a week since it had four more pallets to run.

The Kiwas can machine virtually any part Baum’s customers typically order, including challenging hog-outs of aluminum for aerospace applications, which require substantial material removal, complex features and long cycle times.

Among the many features that make the multi-pallet HMCs optimal for these types of parts is the through-spindle coolant feature and easy chip removal, says Jason Bogert, shop foreman. The spinning auger and conveyor design take care of chip removal without the need to manually push out chips. Coolant blasts from the spindle also remove chips, preventing re-cutting and keeping parts clean.

Prior to the acquisition of the Kiwa HMCs, Baum machined complex parts on its VMCs in three to five operations. This required extensive skill and increased the number of variables that could result in errors and scrapped parts. Now, parts can be completed in one or two operations, which greatly decreases setup time, Mr. Baum says. In fact, setup time has decreased from an average of eight hours to two. Jobs can be set up simultaneously using multiple pallets, which enables the spindle to continue running and make money. Spindle utilization on the HMCs is more than 90 percent (on a 24/6 basis) compared with the 35 percent on a typical VMC.

“Generally speaking, one Kiwa is worth three to four VMCs in terms of productivity, and only one operator is required instead of two to four,” Mr. Baum says.

Along with improving setup time, the HMCs enable Baum to run lights out more consistently. The shop’s six-pallet Kiwa-Japan KH-45 machines run nights and entire weekends unattended, completing several different jobs. Multiple pallets and macro programs (looping logic) enable an operator to run one part or many, simply by changing a few macro variables, says Ben Meyer, director of engineering. A broken tool detection feature skips to the next pallet if a tool breaks during a run. The program and tool numbers are stored in macro variables so the machinists know what to check in the morning.

The HMCs feature a box-type bed, a stepped base and column-casting design to reduce column mass while increasing rigidity and accuracy. The KH-45 also features a stable posi-lock pallet clamping design to further increase accuracy. X-, Y- and Z-axis travels measure 25.2 by 24 by 26.8 inches. To maximize speed and reduce cycle time, the machines feature more than 1G acceleration and 2,362-ipm rapids on all axes. The machines’ reliability, precision and standard fixturing have also contributed to Baum’s bottom line.

“At the end of the day, we are so pleased that we made the move to the Kiwa horizontals,” Mr. Baum says. “They are much easier to install and operate than you may think, and the quantum productivity increases, quality and savings cannot be denied.”

Related Content

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More