Methods Seeks the Perfect Machining Environment

With its new Precision Center, Methods Machine Tools is locking down environmental variables that could impact machining processes. Why? So North American manufacturers will no longer need to send parts, tooling and material to Japan or somewhere else to have intricate, sensitive or challenging test cuts performed.

Share

With the crash of wooden mallets upon the lid of a sake barrel, Methods Machine Tools’ new Precision Center was officially open for business. The traditional Kagami biraki ceremony took place June 5 with executives from companies that have partnered with Methods to help test and launch the ultra-environmentally controlled facility.

At its core, Methods’ new Precision Center is meant to remove all environmental variables that could impact the performance of machining centers and equipment when extremely tight tolerances are required. Customers who may have difficulties achieving extremely tight tolerances, for instance, could turn to the center to rule out — or pinpoint — variables within their own facilities as the culprit. These variables fall across two broad categories: the climate conditions and air pressure within the room itself, and an ultra-solid foundation to minimize machine vibration.

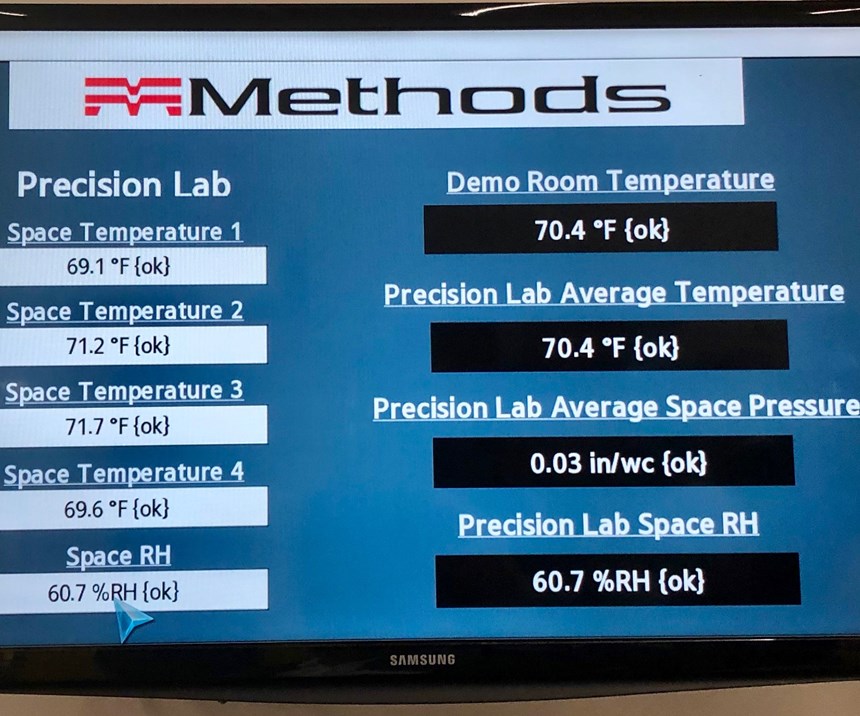

The environmental control technology within the Center is akin to what one would imagine exists on the International Space Station. In order to maintain ideal air pressure conditions, visitors must first pass through a secured, pressurized airlock before entering the facility. Inside, four sensors on the walls and ceiling monitor temperature, air pressure and humidity. They feed that data back to a central control center, which then automatically adjusts ceiling fan speeds, moisture levels, and temperature by engaging or disengaging HVAC units, a water-cooling system and dehumidifiers. All of this takes place without human intervention.

To create the foundation for the Center, a construction crew removed rock and soil 1-meter deep and replaced it with isolated pads for each machine, made up of crushed stone and concrete reinforced with 0.625-inch steel rebar both horizontally and vertically. Methods says this will eliminate vibration and other physical interference that could emanate from the foundation itself during machining operations.

At the event, Jerry Rex, President and CEO of Methods, said that the Precision Center is the largest and most stable machining environment of its kind in the United States. He said that, prior to the grand opening, his team tested the environmental controls by cycling five machining centers for four weeks non-stop and discovered that the greatest temperature variation within any 24 hour period reached only 0.4° F. Because of the technology and stability in the Center, he said, North American manufacturers will no longer need to send parts, tooling and material to Japan or some other country to have their intricate, sensitive or challenging test cuts performed. “There are situations where the environment makes an impact on the machining process that you cannot have,” he said. “We have control over those variables now. Intricate, challenging, tight tolerance and confidential test parts can be made right here in the U.S."

In addition to test cuts and work on confidential parts, Mr. Rex mentioned that the Center will be used to develop new technology around machining practices and advanced turnkey solutions, as well as to develop new cutting tools and in-machine inspection processes. Joining Mr. Rex for the grand opening were Hiroyuki Uchida, Senior Executive Vice President and CTO, FANUC Corporation; Kenichi Nakamura, President Nakamura-Tome Precision Industries; James Hu, Chairman of Litz Hitech; Nobumasa Kiwa, President Kiwa Japan; Takuto Yasuda, President Yasda Precision Tools K.K. as well as owners and board members from Methods Machine Tools.

Related Content

Grob Mill-Turn Machining Center Provides Flexible Performance

The G550T mill-turn universal machining center offers optimized milling and turning performance for a broad range of part materials in one setup.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreIndustry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read MoreRead Next

When Machining Long Parts, Machine Shop Climate Matters

Machining long titanium tufting needle bars required a milling machine with a super-long X-axis travel. But the real challenge was thermal compensation in the Georgia heat.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=970;quality=90)