Large Y-Axis VMC Enables Complete Machining in Single Setup

When Sarro Manufacturing couldn’t manufacture large, aluminum plates in one setup, it installed a Feeler VMP-1100S from Methods Machine Tools Inc. The VMC cut cycle time and spiked productivity.

Share

Maintaining accuracy when manufacturing large parts can be a challenge, especially when multiple setups are involved. Sarro Manufacturing in Newton, New Hampshire, encountered this problem when manufacturing large plates made primarily from aluminum. When the shop purchased a Feeler vertical machining center from Methods Machine Tools Inc. (Sudbury, Massachusetts), the ability to machine complete in one setup saved Sarro both time and money as well as increased productivity.

The 20-year-old company is owned by Bruce Sarro and run by eight employees in a 5,600-square-foot facility. Sarro chiefly manufactures for the defense, microwave and printed circuit industries using a range of materials, including aluminum, plastics, stainless steel, copper and brass. Its customers demand on-time delivery to meet tight schedules, and several require a quality rating of 97 percent or better.

In 2011, Sarro encountered a problem when manufacturing large plates, many of which measured 20 by 20 inches and 28 by 21 inches with thicknesses ranging from 1/8 to 1/2 inch. “The biggest issue was not being able to reach all the way around our large plates in order to machine them in a single setup,” says Bradd Sarro, director of operations, and Bruce’s son. “We could only reach so far on the Y axis, so we had to manually flip the part around to complete the job.”

Along with their capacity limitations, Sarro recognized that its smaller machining centers were not keeping up with newer, more robust technology available to them. For instance, the older machining centers had slower spindles, and coolant-through capability was not very powerful. Also, workholding capability was limited. “We were only able to put two vises in the setup, which was not enough for our large plates,” Mr. Sarro says.

Faced with this dilemma, Sarro turned to Methods Machine Tools, its long-time supplier. To meet the large-plate machining requirements, Methods recommended the Feeler VMP-1100S VMC because of its 23.6 by 47.2-inch table that can handle a maximum load of 3,000 pounds. To further accommodate the large parts, the VMC’s travels measure 43.3 by 24 by 23.6 inches on the X, Y and Z axes, respectively. Its 25-hp, 15,000-rpm, 40-taper spindle; FANUC Oi-MD control; and 1,000-psi through-coolant capability provide sufficient power to quickly machine the large plates.

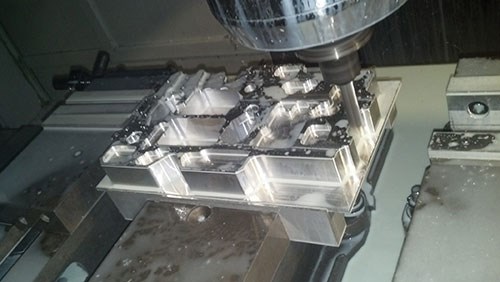

The VMP-1100S also eliminates workholding challenges for this job. The company now uses four 6-inch vises to accommodate four work coordinates. Sometimes, they even fixture on the table without vises, Mr. Sarro says.

The VMC’s other features include a standard 30-tool, dual swing-arm ATC; linear guideways on the X and Y axes; and boxways on the Z axis. According to Methods, advanced engineering on the VMP series makes it well-suited for a variety of precision industrial requirements. Finite element analysis (FEA) and a reinforced A-shape Meehanite column are combined with a massive base to increase accuracy, rigidity and stability. A fine-grain cast iron machine structure and high-speed servo system enable A-axis rapid traverse rates ranging to 48 meters per minute.

After bringing the VMC online, Mr. Sarro says he has been extremely pleased with the results. The Feeler eliminates secondary tapping requirements and removes the need for multiple-operation setups. “Now our plates can be done in one shot, one setup, complete,” Mr. Sarro says. “With the high-pressure coolant and 15,000-rpm spindle features, we were able to cut machining cycle time down on two of our largest production jobs by 30 percent.”

Although Sarro originally purchased the Feeler VMC with existing applications in mind, it has also enabled the company to take on jobs that previously would not have been possible. For instance, one application requires cutting and tapering a face plate measuring 0.25 inch thick by 6 inches long by 2.5 inches wide. Sarro uses the Feeler along with 3D surface milling technology from GibbsCAM. The single-setup job requires a 1/8-inch ballnose end mill running at 100 ipm and spindle speeds of 10,000 rpm, which were not possible with the company’s previous machines.

In another application, Sarro needed the Z travel on the Feeler to machine end holes in a large aluminum plate for a support upright part that measured 2 inches thick by 14 inches long and 8 inches wide. “To accomplish this job, we needed some large tooling as well as sufficient horsepower and spindle speed for the rapid material removal required. Using a ½-inch radius cutter, the Feeler easily machined the plates within a short cycle time with no more than 10 percent load on the spindle,” Mr. Sarro says.

Another application required machining a 1.25-inch thick by 11.25-inch long by 6.75-inch wide top plate with a small radius. The program size and spindle speed were best-suited for the Feeler machine. The company was able to leave the job running for 8 hours of lights-out operation, because the Feeler is set to automatically power off. This reduced labor costs and increased productivity.

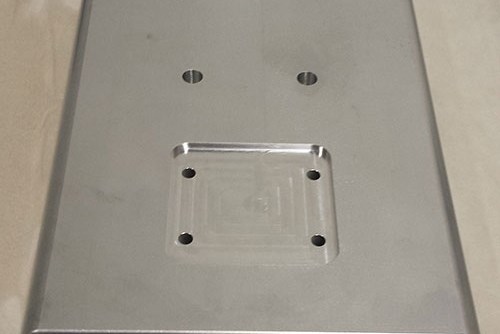

The company says that the machine provides exceptional tolerance for smaller-part work as well. In one of its larger-production jobs, Sarro needed to produce a 6061 aluminum heat sink part measuring 5 by 1 by 1 inch. To complete the part, the company used the Feeler to run a 1/8-inch end mill at 30 ipm with 300-psi through coolant and spindle speeds of 8,000 rpm. Mr. Sarro set up the part using four vises and the same number of work coordinates. Due to the spindle speed and powerful coolant-through capability, the company was able to increase tool life, he says, and cut cycle time by 30 percent.

Along with an increase in productivity, the Feeler machine also increased reliability and repeatability. “With glass scales, the hole-to-hole accuracy is always dead-on, well under ±0.0005 inch on hole location repeatability,” Mr. Sarro says. On the 6061 aluminum heat sink part, Mr. Sarro says he was able to contour holes consistently every time within ±0.0002 inch.

Although aluminum is the main material Sarro currently machines with the Feeler VMC, the company recently had positive results using 316L stainless steel for a one-off prototype manifold job. “We tried it in aluminum first with great results and then decided to give stainless steel a try. No problem,” Mr. Sarro says.

Using the Feeler machine, Mr. Sarro says that the company has been able to take on new jobs since it powered up the machine. In fact, it recently accepted a new job for a needle array plate for the biomedical industry, even though it’s not the company’s primary industry. Additionally, “We have been increasing the speeds and feeds on each new job without issue,” he says.

“We would not hesitate to acquire more Feelers when the time is right,” Mr. Sarro says. “It’s comforting to know how quickly we can get up to speed on running them.”

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=970;quality=90)