10 Ways to Think Differently about Robotic Automation

Take another look: A lot is happening in and around robotic automation. What robots might mean for machining and manufacturing is getting ready to change.

Share

Robots used to know their place. In the past, a robot would run behind a safety cage doing repetitive motions that rarely changed from week to week, let alone from day to day. Now it’s not so simple. Robots are, in many cases, easy to redeploy; collaborative robots (cobots) operate safely alongside people; and other advancing technologies seem to conspire with robots to make them even more effective. The result is an expanding scope of what robots might mean for manufacturing. Gathered over months from various events, discoveries, observations and conversations I’ve been party to recently, here are many glimpses of the changing nature of robots. Consider these points as a means of uncaging your own thinking about robotic automation, and perhaps even reconsidering what a robot might do for you:

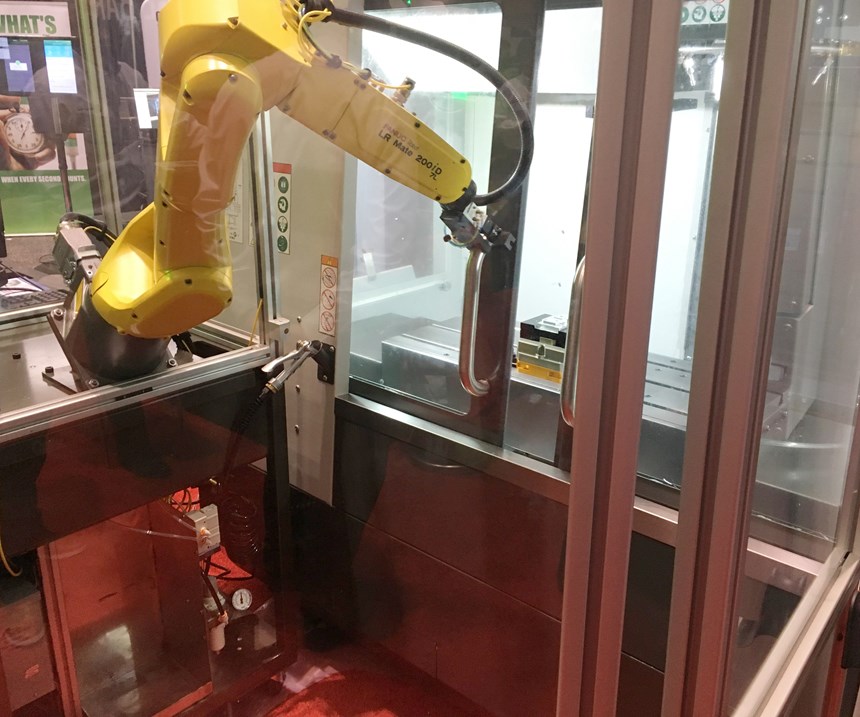

1. Machine tool builders are adapting to robots. United Grinding’s Flexload, for example, is an add-on automation module by which the robot enters through one end of a grinding machine. The doors are still available for the operator, but for the sake of safety and temperature control, the robot’s access is different.

2. Robots are now seen to leverage labor, not replace it. Thyssenkrupp North America CEO Patrick Bass made this point at a recent Financial Times Live conference on manufacturing. The impact of low-cost automation such as a cobot includes the enthusiasm and engagement of the employee who has this resource, he says. A worker costing $67,000 annually becomes significantly more effective with the one-time investment in a $30,000 cobot.

3. Autonomous vehicles link robots’ efforts. Methods Machine Tools demonstrated this at the Smart Manufacturing Experience this year. A robot unloading parts from one machine placed them onto a self-guided vehicle delivering them to a different robot collecting the parts for inspection. The vehicle found its way around obstacles such as people, showing that a fixed track is no longer needed for automated systems to interconnect.

4. Redeployable robots simplify automation. Between cobots and traditional fixed industrial robots are redeployable robots mounted on platforms that make them easy to install and move from machine to machine. The Morris Group demonstrated an example of this from APT Manufacturing Solutions at the Smart Manufacturing Experience as well, and we recently wrote about a shop that is thriving with the approach to this idea from Halter.

5. China is the fastest-growing nation in robot use. This is partly a result of a deliberate emphasis on the technology by this country’s government. What we think of when we imagine manufacturing in China might change.

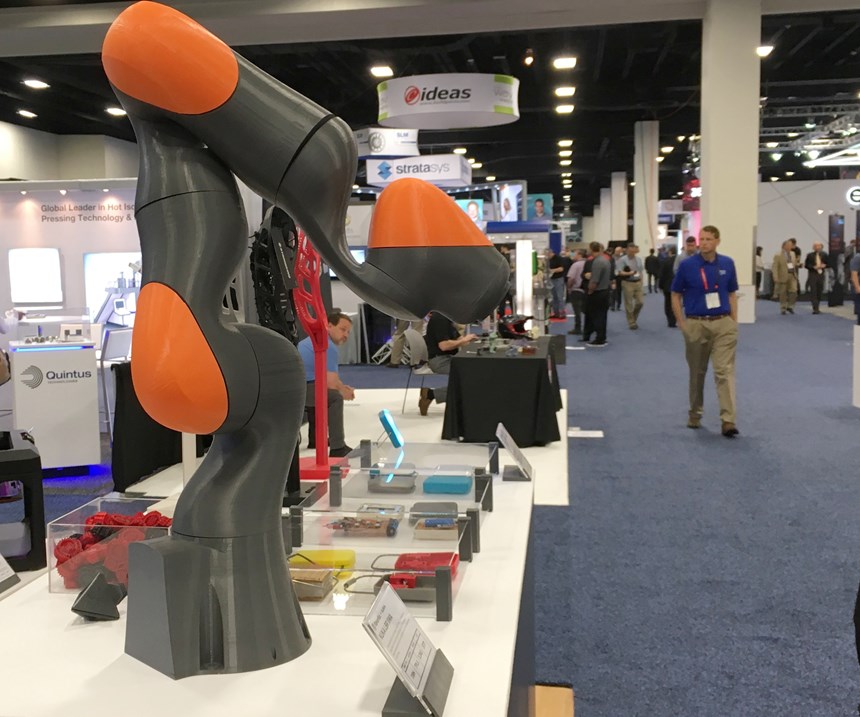

6. 3D printing is a complement to robotic automation. The one part-specific component of any robot application is liable to be the gripper. A 3D printer addresses this by offering a way to produce customized grippers or end effectors quickly. Additive manufacturing even realizes grippers that couldn’t be made another way.

7. Robot engineering addresses tight spaces. 3D printing also provides a means of prototyping the complex motion of robots designed to operate within a tight footprint. At this year’s Rapid + TCT event, MakerBot illustrated this with a 3D-printed robot prototype created by design engineers at Kuka Robotics for their KR 3 Agilus robot.

8. Inspection is an opportunity for robots. We think of robots doing the repetitive work of loading and unloading machine tools, but inspection is also repetitive work. Arnold Gauge was recently involved in an example: A customer needed 16,000 parts inspected by laser interferometry to detect a potential chatter problem in ID grinding. Company president Michael Bruns says a co-op student working on the problem less than a day was able to program a cobot to perform all the part handling for this inspection.

9. Cobots bring automation to old machines. Since they are inexpensive robots, cobots provide great opportunities for automating what might otherwise be considered lower-performing machine tools. At a recent event on robotics, TechSolve demonstrated a cobot from Universal Robots automating an older CNC lathe. No integration was needed, since the programmed motion of the robot included pulling the door handle to open and close the machine and pressing the control’s cycle-start button.

10. People are still needed. At that same TechSolve event, Robert Graff, senior sales manager of STEM education for Yaskawa America, described the need for robotics personnel seen by one manufacturer in particular, Honda’s Ohio plant, and what lengths this plant is taking to fill that need. A particularly fast-growing job title is “robot coordinator,” he says. Robots do replace human labor in some cases, but they are also driving the demand for different kinds of manufacturing professionals.

Related Content

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)