Sharing The Big Picture

The theme of visibility in manufacturing finds expression in numerous ways at this shop. One of the most conspicuous is the use of plasma displays in strategic areas to summarize the company’s performance as reported by its shop control/data-collection system.

Share

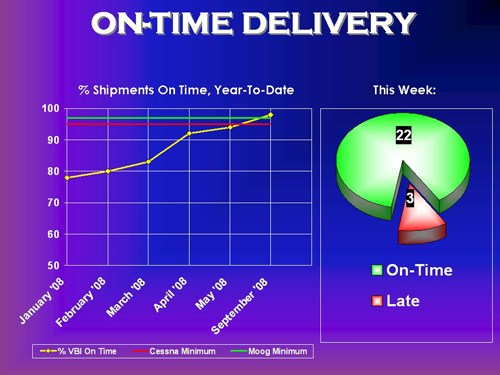

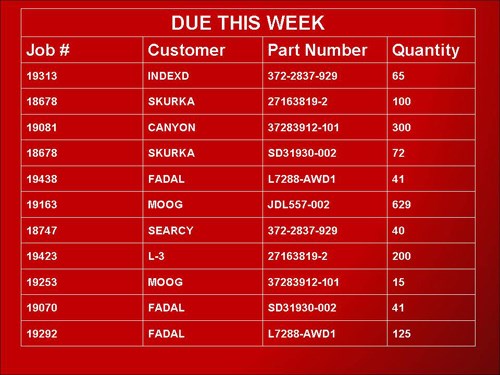

The plasma screen display over the main shop area at Vanderhorst Brothers Inc., a 30-person shop in Simi Valley, California, would be hard to miss. That’s the point. The plasma display shows key information about the shop’s overall performance in alternating PowerPoint slides. Each slide displays a summary of key performance data: monthly sales to date, on-time delivery, jobs due within the week and jobs shipped today.

Brian O’Rell, company president, believes that this high visibility is critical to the shop’s success. “It’s a picture of what’s happening,” he says. He hopes the picture is always a positive one, but sometimes it isn’t—and that needs to be seen by everybody, too, he says.

The data shown in the slides is current. They reflect information summarized from the company’s shop control/data-collection system. The reports generated by this software are management tools meant to help Mr. O’Rell and his top managers make good decisions about shop activities. These top managers include Mr. O’Rell’s wife, Juno (the company controller), their son Bob (who manages the integration of new projects into palletized machining centers), and Josh Church (the shop’s quality manager). All rely on this software to do their jobs. As Mr. O’Rell explains, “These reporting tools give our shop visibility. That is, they help us see where we are having problems and where we are making progress.”

The two plasma screens—one by the coffee maker in the central lobby and one mounted in the machining area—bring that visibility to the rest of the employees. “Everyone in the shop has a better view of what’s going on,” Mrs. O’Rell says. Of course, “everyone in the shop” includes shop visitors, some of whom may be customers. They can see the status of their jobs, too.

Mr. O’Rell admits that occasionally this isn’t an ideal situation when a customer’s particular job happens to be running late. “It doesn’t happen often, but hiding it doesn’t help. We can’t get better if we don’t see where we need to make changes and improvements,” he says.

As it is, sharing information visually has been an important part of the shop’s emphasis on better communication. “The value of communicating effectively with our workforce was one of the main lessons we learned from the SCMG,” Mr. Church says, referring to the Southern California Manufacturers Group, an association of local aerospace shops that meet regularly to assist one another in their self-improvement efforts. Providing all employees with the big picture of a shop’s performance is one of the “best practices” endorsed by a consensus of group members.

A Shop In Transition

Mr. O’Rell would certainly agree that his company has seen a lot of change lately. Some of the biggest changes have occurred in the last year and a half, a period when the shop installed several palletized machining systems. These machines mark the most dramatic step in the company’s transition from a job shop to an aerospace production house based solidly on the principles of lean manufacturing. Mr. O’Rell says that this change started about 8 years ago.

At the time, the shop’s business was about 80 percent commercial job shop work—mostly simple work in small batches—and 20 percent aerospace. Mr. O’Rell and his wife had recently acquired the company from its original owners, Hank and Ed Vanderhorst, who founded it in 1973. Mr. O’Rell had joined the shop in 1983, so he had a clear idea of the shop’s past direction and the path it needed to take in the future.

He could see that the company had to transform itself in order to survive. The simpler job shop work was likely to move overseas, but the more difficult, higher margin work was likely to grow. However, growing that side of the business would involve new technology such as five-axis machining, wire and ram electrical discharge machining (EDM), multitasking mill-turn machines, and automation for unattended operation. It would also require developing new

skills, both on the shop floor and in the office.

“We knew we couldn’t make all of the changes at once; that it would have to be a step-by-step process,” Mr. O’Rell recalls. This meant setting priorities and concentrating on the most important things first. A lot of guidance and good suggestions for making the right choices came from the Supplier Excellence Alliance (SEA), a membership organization consisting of prime contractors, Tier-1 suppliers and other supplier companies in the aircraft, defense and space industries (www.seaonline.org). SEA was formed in 2004 to promote the adoption of lean manufacturing and other techniques that bolster supply-chain efficiency and competitiveness. Vanderhorst Brothers joined in 2005.

Membership in this organization gave the O’Rells and others on the management team a chance to learn what the big aerospace firms look for in their manufacturing partners. “We quickly realized that to stay in the aerospace business, we had to do it right,” Mr. O’Rell says about plans for change in his shop.

Being part of an active peer group such as the SCMG has also provided benefits, especially the opportunity to see what similar companies are doing. Shops in the group meet to share ideas and learn from their experiences. For example, several members are implementing various aspects of lean manufacturing, so sharing advice and practical suggestions is helpful. Members also tour one another’s facilities. “We got a picture of what our own shop should look like from seeing other successful shops,” Mr. O’Rell says.

It was this vision that largely inspired him to acquire the palletized machining centers. A Matsuura MAM72-35V, a vertical machine, was installed in June 2007. The shop worked closely with Selway Machine Tool Co., the builder’s local distributor, to configure the system and equip it adequately with pallets and tooling. This five-axis machine is integrated with a vertical pallet pool that accommodates 32 pallets. It was the first of its kind in Southern California. A 240-pocket carrousel keeps all the tooling for numerous jobs at the machine. The shop quickly learned to run this machine in unattended mode during nights and weekends.

About six months later, the shop completed installation of a cell consisting of two Toyoda FH450S five-axis HMCs integrated to a linear pallet system that uses a rail-guided robot to store and retrieve 450-mm pallets. The system accommodates 42 of these pallets on three tiers. Each machine has a carrousel holding as many as 494 tools. Selway was also the source for this system.

For a shop of this size, bringing in these palletized systems and getting the shop acclimated to their operation has been a major preoccupation. Nevertheless, the shop simultaneously undertook several other initiatives in keeping with recommended modernization programs. One of those was establishing a homegrown training and incentive program called Operation Top Notch. For this program, the management team set up a matrix of prioritized training classes that follow SEA’s recommended training guidelines. Upcoming courses are posted where all can see, and employees are encouraged to enroll. Other improvement initiatives focus on areas in which excellence is likely to lead to increased sales, and in turn, to increased earning power for employees.

The idea for the plasma displays also grew out of experiences with the peer-group meetings. Good communication was a constantly recurring theme in discussions and presentations. For the O’Rells, the whole issue of sharing a picture of shop performance was especially urgent because of all the changes going on in the company. They believed that this picture would validate the new direction of the shop while reinforcing the importance of meeting customer expectations.

From JobBoss To PowerPoint

The first plasma screen, located by the coffeemaker, was installed in late 2006. This location was chosen because it is a high-traffic area for both shop and office personnel. The second screen was put up in March 2008. The screen is mounted in a spot once occupied by a dividing wall that was removed in preparation for the Toyoda cell, thus turning a barrier into a “beacon of visibility.” The front of the screen faces most of the shop’s manned workstations.

The slides alternately appearing on the screens are simple. They have to be for effect—the meaning of the information conveyed has to be grasped at a glance. The slide showing month-to-date sales is simply a graph with a line that moves from point to point toward the end of the month (ideally in a steady, upward direction). The on-time delivery slide shows a pie chart with a slice representing the percentage of late shipments, if any—emergency jobs taken on as favors to good customers is the usual cause for this “bad slice” to appear. Likewise, the slide showing jobs due during the current week is simply a list of job numbers, customers, part numbers and quantities due. The total value of shipments for the day appears on another slide.

The simplicity of these displays is both revealing and concealing. It reveals some important features and characteristics of the shop control/data-collection software that provides the data. However, the simplicity conceals the resourcefulness and diligence of Mr. Church, who designed the slides and wrote the macros that keep the displayed data up to date.

“We started using JobBoss from Exact Software in April 2002. This software made it possible to build the display system that taps into it,” Mr. Church explains. Of course, the software was originally acquired on the strength of the modules the shop needed most. Currently, Vanderhorst uses the Job Entry module, the accounting module, the ShopBoss scheduler, the quoting module, the material control module and the data collection module.

According to Mr. Church, one reason why this software has proven valuable to the company during its transition is that it is extensible. This means that third-party software programs can be linked to this software for a seamless exchange of data between applications. One of these programs is Crystal Reports, which users can obtain directly from JobBoss. Crystal Reports is designed to easily create customized reports that extract data from standard database systems. Other applications can also take advantage of JobBoss’s extensibility, including custom programs or even short macros.

In this case, Mr. Church used PowerPoint to create the slides and charts (initially based on sample data). He then created a macro for each slide using VBA (Visual Basic for Applications). Each time the PowerPoint presentation advances to the next slide, the appropriate macro is executed. The macro connects to JobBoss using its standard ODBC (Open Database Connectivity) interface. It then automatically queries the database and updates the data for each slide. In turn, PowerPoint automatically updates the graphical charts to reflect this new data. The underlying hardware is relatively simple—the plasma display serves as the monitor for a standard workstation (connected to the company’s network) running PowerPoint.

Much of the data in JobBoss—such as due dates, shipped jobs and on-time delivery—is updated in real time. Other data, such as shopfloor performance, is updated at least once every shift. The company has 10 computer terminals in the shop and office areas for entering data and querying the database. On the shop floor, operators can enter data such as part count, machine time and status when operations are completed or at the end of a work shift. As data is entered, the slides on the plasma screens are automatically updated.

Picturing The Future

With many developments and changes to contend with, Mr. O’Rell expresses some frustration with the fact that some things he wants to make happen for his shop have to wait. Doing more with the shop control/data-collection software is one. “We’ve only scratched the surface of what we can do with the customized reports from JobBoss,” he says. “Although we have the most important information at our fingertips now, we know we are overlooking some of the details that could be organized and presented in a meaningful format for us.”

For example, the shop is already using a custom Open Order report to communicate with customers regarding part stock, schedule status, delivery dates and other vital information. Recognizing the value of this customization, Mr. O’Rell is eager to explore other opportunities to sharpen his image of the company’s performance. He says it is good to know that the software can grow and change as his company does.

In the meantime, Mr. O’Rell has his hands full with a number of urgent matters—a typical situation for shops like his, as he gathers from listening to other shop managers in his peer group. An immediate concern is completing the auditing process for certification under AS9100, a quality standard for aerospace manufacturers issued by the Society of Automotive Engineers. Vanderhorst is already certified for ISO9001-2001, but a number of customers have alerted their suppliers that compliance with AS9100 will also be required. AS9100 requires deeper documentation, more thorough planning, more detailed supplier management and other improvements. The final external audit is scheduled for the first quarter of 2009.

Also on the horizon is an upgrade to the shop’s inspection capabilities. The shop is evaluating direct computer controlled (DCC) coordinate measuring machines (CMMs) to automate part inspection. Its inspection areas are well-equipped with metrology instruments, including a Mitutoyo CMM, but they could become a bottleneck because aerospace parts are increasingly complex and tightly toleranced. Mr. O’Rell points to a computer housing for a 737 jetliner as as an example. This part, about the size of a textbook, has 1400 dimensions.

This part went into production before the palletized machining cells were installed, so the existing process involves operations on several stand-alone CNC machines. As time permits, this part’s process will be re-engineered for done-in-one production in five axes on one of the cells. The new process will require using the shop’s unique fixturing system. In this system, all blanks are pre-machined with a standard shape that matches modified clamping components.

Looking beyond these short-term projects, however, the O’Rells envision another eventuality to prepare for—retirement. Down the road, they expect to see the next generation of owners and leaders to take over responsibility for the company. Younger members of the management team, such as their son Bob and Josh Church, will have to be prepared to keep the current momentum going.

According to Mr. O’Rell, this vision of the future is part of the picture in which the new machining cells figures so prominently. Mr. O’Rell believes that these cells—and the lean manufacturing principles they embody—will position the company for lasting competitiveness, even in the face of a globalized market for aerospace production. “We want Josh and Bob to grow with this technology and be part of making it happen,” he says.

In the months and years ahead, the company does seem to have a lot to look forward to.

Related Content

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More