Dedicated Multitasking Machine Is the Answer for a Complex Medical Part

Precision Swiss Products Inc. needed a machine that could accommodate a dedicated job with a unique material/application. A Nakamura AS-200 multitasking center with chip-management system from Methods Machine Tools produced enabled production of high-quality parts in a short lead time.

Share

To meet the demand for high quality, short lead times and competitively priced parts, successful manufacturers find ways to optimize their manufacturing equipment, ensuring the most effective, efficient production process for the application at hand. However, when considering a new job or application, those manufacturers must take into account that not all machine tools are created equal—what works for a high-mix/low-volume operation might not be the best fit for a complex, high-volume application.

This was the case for Precision Swiss Products Inc. (PSP) of Milpitas, California, when it decided to take on an attractive, but dedicated high-volume job manufacturing a non-conventional part. A turnkey multitasking center from Methods Machine Tools Inc. (Sudbury, Massachusetts) helped the company produce a high-tolerance, high-quality part

PSP is a 65-employee company that operates in a 22,000-square-foot manufacturing facility located in Silicon Valley. The shop’s two wire EDMs, three HMCs, six VMCs, four lathes, six FANUC RoboDrills, 14 Swiss machines and passivation equipment are used to produce extremely complex, tight-tolerance components for the medical and aerospace industries that routinely require micron-level accuracy. PSP maintains a partnership with a team of design for manufacturability (DFM) experts to help lower costs and lead times without compromising quality. In the near future, the company says it plans to expand its facility an extra 15,000 square feet to accommodate increased manufacturing and assembly demands. It also plans to continue tackling higher tolerance work.

In fact, COO/CFO Steve Dillon says the company is moving away from low-volume/high-mix applications to high-volume dedicated solutions. For example, PSP took a job manufacturing a component for a heart valve delivery system in which a stent is used to expand blood vessels to the heart and implant the heart valve. The company manufactures about 1,250 of the Lexan polycarbonate resin parts per week, which measure approximately 1 inch in diameter by 2 inches long.

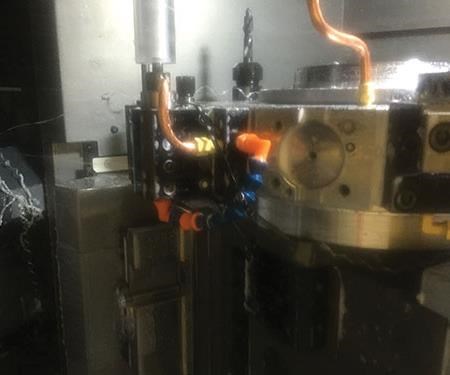

To figure out how to handle this part in a high-production run, PSP turned to Methods Machine Tools. In the end, Methods proposed the Nakamura AS-200 high-performance multitasking turning center and a custom-programmed chip-management solution for the job.

“We were a bit skeptical that finding the right solution was going to be an easy process, because it is a very unusual, difficult part to machine. We have to be very careful not to let the friction and heat melt the part, because we’re working with Lexan,” says Norbert Kozar, CEO at PSP. “We sent Methods solid models and a part diagram. They programmed the part, made refinements and within a month, we were ready to move ahead on producing it. We were incredibly impressed with the engineering expertise and service we received.”

The AS-200 was installed in March 2015. The 12-station (24-tool-capacity) turret has a 7.5-hp milling motor and a top rotational speed of 6,000 rpm to provide power with a maximum turning diameter of 13.4 inches (340 mm) and maximum turning length of 11.8 inches (300 mm). The high-speed C axis and 82-mm-stroke Y axis add to this flexibility. The turning tool is 1 inch (25 mm), and the inside boring shank measures 1.25 inches (32 mm).

The machine also is equipped with a FANUC OiTD controller, providing a high degree of

functionality coupled with fast processing speed.

“The part is fairly complex and requires both inner- and outer-diameter Acme threads, which produce many nuisance chips,” Mr. Kozar says. Initially, the AS-200 was producing foot-long chips that were slowing down the production process. To address this problem, Methods created a chip-management system using a single-point, 60-percent carbide bar for pecking along with programming solutions to cut the chips down to a much more manageable size of 4 or 5 inches.

“The frequent pecking action, along with the friction and heat generated by the production process, creates substantial wear on the tools,” Mr. Kozar says. “We are currently running diamond-coated drills in an effort to further extend tool life and reduce downtime related to changing worn-out tools.”

The Nakamura AS-200 was just what the doctor ordered for this complex part. “We were very impressed with the turnkey solution Methods provided,” Mr. Dillon says. “The AS-200 is running mostly lights out, approximately 20 hours a day, consistently providing high-tolerance, exceptional quality parts. Methods’ expert engineering experience was critical in determining the ideal dedicated solution for our application. The service team was here at a drop of a hat to ensure the ongoing efficiency of making the part. They delivered on what they promised, driving the ROI for PSP. Their technical team programmed the part efficiently from the start.”

While performance is a key component of success, today’s manufacturers also need to be able to justify their investment in a new solution. According to Mr. Dillon, payback was incredibly fast for PSP. The company attained breakeven within six and a half months.

According to Mr. Dillon, machine installations and qualifications often encounter some hiccups, but Methods made these challenges seem insignificant by providing sales and engineering support, even on the weekend. In fact, Methods Sales Representative Armand Flemate orchestrated a Saturday afternoon exchange of a high-pressure coolant pump. By Monday afternoon, PSP had a high-pressure coolant pump that resulted in an improved chip control system. “This type of service and commitment is hard to find in this industry, however, it is the most overlooked attribute of new machine acquisition,” Mr. Dillon says.

Related Content

Grob Mill-Turn Machining Center Provides Flexible Performance

The G550T mill-turn universal machining center offers optimized milling and turning performance for a broad range of part materials in one setup.

Read MoreWFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreIntegration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=970;quality=90)