Automation Events Highlight Deburring

This tedious, costly and complex operation was one focus of two complementary, same-day events that covered virtually every aspect of industrial robotic automation.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Whether they were transporting parts, building complex assemblies or serving iced cream, the robotic displays on the floor at Applied Manufacturing Technologies (AMT) during the recent amtExpo made automation look easy. However, anyone with first-hand process-automation experience can attest that integrating robots can be anything but. Hosted August 9-10 in Orion Township, Michigan, the automation engineering specialists’ event provided opportunities to network with 400 people and 60 different companies to learn about what it takes to successfully automate.

One of the more complex tasks that’s both common to machine shops and highly beneficial to automate is deburring. While application displays left little doubt about the possibility of automating this process, attendees who had the opportunity to attend a complementary event down the street learned that technology isn’t necessarily the biggest hurdle to doing so.

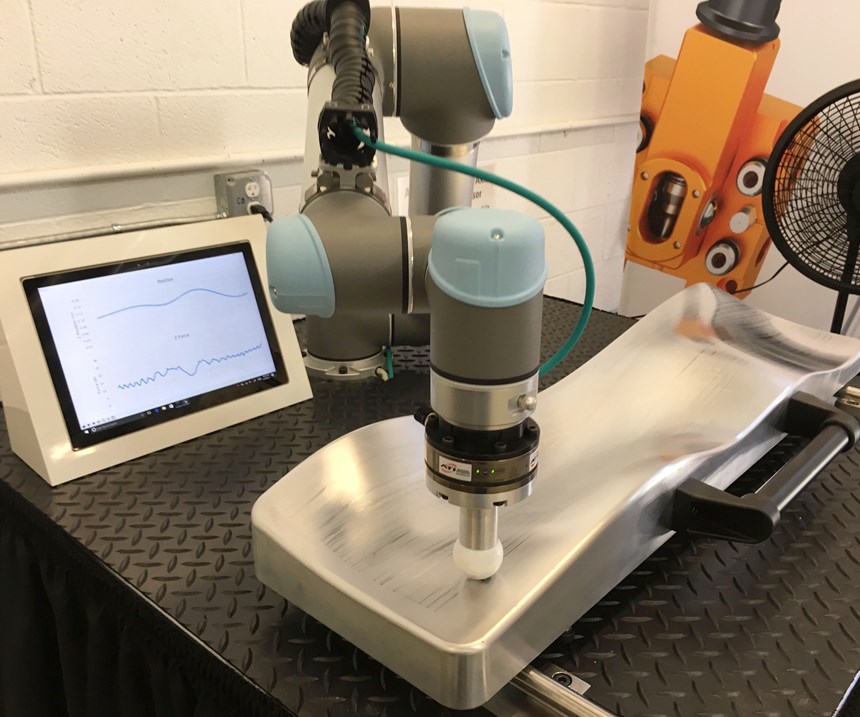

Accessible via a short shuttle ride from AMT, ATI Industrial Automation’s Annual Technology fair highlighted applications of the company’s automatic tool changers and force/torque and collision sensors. There, presenter John Lucier, national automation manager for Methods Machine Tools, explained that part of the battle of automating deburring is convincing manufacturers that it’s worth doing in the first place.

The problem isn’t motivation, he says. After all, manufacturers that still deburr manually certainly understand the financial (and sometimes even physical) pain that comes with using hand tools to smooth minute imperfections on part after part. They understand that this work is tedious, potentially dangerous, inconsistent by nature and renowned for bottlenecking production lines. Where they tend to balk is the seemingly high cost of robot arms, particularly in comparison to the cost of the machines doing the bulk of the metalcutting in the first place. Mr. Lucier argues this comparison is wrongheaded. That is, the cost of the robot arm shouldn’t be compared to that of any equipment, but rather, to the cost of the labor it will replace (typically, the salary and benefits of a skilled person who can often be better repurposed elsewhere). In fact, Mr. Lucier made this same cost-comparison argument earlier this year in an interview with Modern Machine Shop, resulting in an article with an accompanying video of a complex deburring and cleaning cell.

Even with a clear understanding of the potential return on an investment in automated deburring, how should a manufacturer actually implement it? Here are a few tips courtesy of Charles Young, senior product manager of metal-finishing specialist Acme Manufacturing Co. and another presenter at the ATI event:

- Do the work by hand first. Deburring is a complex task, and it can’t be rushed. Doing things the old-fashioned way first can help manufacturers determine the right tooling, parameters and other process inputs more easily than would be possible by working it out on a robot from the beginning.

- Be wary of offline programming. Granted, it may well be possible for the application, and it may save significant time. However, along the same lines of the above, deburring is an operation that benefits from the “feel” that can come only on the shop floor.

- Have plenty of parts. How will the chips flush? What will the burrs look like? Answering such questions typically requires working out deburring routines on real parts, not 3D-printed prototypes or other approximations. Make sure enough workpieces are available to develop a truly efficient process.

- Don’t expect robots to be machine tools. They lack both the accuracy and the rigidity of dedicated metalcutting solutions. Let the machine cut the part, and let the robot handle small volumes of material that would be inefficient or impossible to remove on the machine.

- Finish the finishing operation. Removing one burr can often create two smaller burrs, one on each edge of a chamfer. A wire or nylon brush is often well-suited for the necessary cleanup operations.

- Mind your locations. Programmers should pay particular attention to the tool centerpoint, and vision or probing systems should be employed to ensure proper orientation of the workpiece.

Related Content

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)