Automotive Manufacturer Grows through Automation

Gil-Mar Manufacturing met growing application demands on their average machines by partnering with Methods Machine Tools to automate and integrate them.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

While investing in the right machines for a particular application is essential for a company’s success, a sometimes overlooked part of the process is developing partnerships with technological expertise. Gil-Mar Manufacturing Co. of Canton, Michigan, saw that it would need guidance as it entered a time of aggressive growth, because doing so haphazardly could lead to lost productivity, profits and opportunities along the way. By partnering with Methods Machine Tools (Sudbury, Massachusetts), Gil-Mar was able to expand smartly with exponential growth.

Gil-Mar has provided high-quality machining, fabrication and welding of parts for the automotive and defense industries for more than 30 years. It operates three Michigan plants in addition to two facilities in Shanghai, China. The company machines cast ductile iron steering-link components and various engines and auxiliary brackets for Ford, with a focus on the F-series truck program, and a diverse array of machined components for Chrysler. It also makes door-hinge sets and frame-mount housings for Ford via Tier-One suppliers.

Upon experiencing meteoric growth starting in the early 2000s, Gil-Mar began a closer analysis of its production rates, machining capabilities, downtime and support. “It became clear that some of our equipment lacked the technology and capabilities to run at the high-performance levels necessary for our demanding applications and volumes,” says Plant Manager Dave LaVigne. “Average machines, lack of supplier expertise, and mediocre service and support led to increased downtime and losses.”

In one year’s time Gil-Mar also successfully launched 48 new major jobs and acquired a building to expand its Michigan operation. “There were a lot of moving parts,” Mr. LaVigne says. “Around 2008 into 2009, it became clear that we needed to align ourselves and partner with a highly skilled machine tool supplier that could arm us with not only leading machine tool technology and service, but also the vision to help us automate and integrate machines and systems as a whole to enable smart manufacturing solutions for our growing application demands.”

Methods Machine Tools, which has a technology center in nearby Wixom, Michigan, provided the insight and horsepower for Gil-Mar to take notice. “It made complete sense for us to give Methods the nod. It has leading machine brands; excellent integration abilities; application engineering, service and support; and is only 15 miles away from us with a warehouse full of parts and machines under power,” Mr. LaVigne says.

In December 2009, the partnership got off to a fast start. According to Mr. LaVigne, prior to Methods, Gil-Mar was experiencing breakdowns, and poor service and support with its horizontal machining centers. It wanted a new, serviceable machine with a good track record for value and investment, so Methods suggested the Kiwa KH-45. “The overall machine frame and casting is massive,” he says. “The machine is also exceedingly fast with chip-to-chip time of 2 seconds, and tool-change and pallet-change times that blew away the machines we had. We have achieved 20 percent increases in throughput, and uptimes are in the high 90s versus the mid-80s on our previous machines. Our part quality has also greatly improved. The Kiwas are extremely repeatable, and the spindle is always in the cut.”

By manufacturing spring hangers, motor mounts and frame components on Kiwa machines for multiple Ford platforms, Gil-Mar’s reliability and productivity have increased, he says. The company has since added 16 Kiwas to its operation.

Building on this success, the company consulted Methods in late 2014 concerning a large contract opportunity to make cast stiffening brackets for a Chrysler engine. According to Mr. LaVigne, Gil-Mar had a dial index machine designed to handle such an application, but its flexibility was inadequate for the scope of the program and the production requirements. The company’s options were to either acquire a new dial index machine with a fixed spindle dedicated for the application in the price range of $1 to $2 million, or come up with an alternative solution. “We were keen on the latter, because frankly, we were reluctant to make an investment of that magnitude without having the ability to utilize it on other applications in the event of a downturn or demand fluctuations,” he says

Methods was tasked with finding an efficient, cost-effective way to not only solve the problem, but also design a system that would be optimal for Gil-Mar’s overall manufacturing model, says Thomas Saur, general manager at Methods’ Wixom technology center. Automation with Feeler machining centers was the answer.

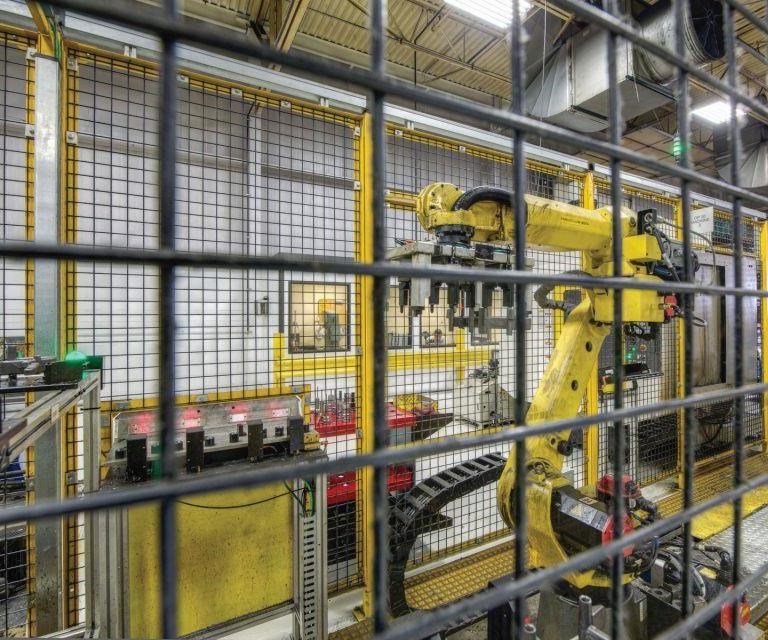

The Methods solution consisted of two Feeler FMH-500 horizontals running in tandem making suspension pairs and one FANUC robot serving four Feeler VMP-800 verticals in a cell making the stiffening brackets. “The yield per hour is running at 80 percent for half the cost compared to the dial index machine, and the cell only requires one machinist instead of two,” Mr. LaVigne says.

In late 2014, Gil-Mar had another opportunity to automate when it was presented with the chance to manufacture door-hinge sets for the Ford F-150, but Tier-One supplier Midway demanded a high-output, premium-value solution. “We saw this as a large cradle-to-grave solution that Midway wanted–very fast, repeatable, reliable and affordable,” Mr. LaVigne says.

Gil-Mar challenged Methods to develop a solution for the program. “With a scope of 180,000 parts times four doors, and on-demand delivery and cost a key consideration, automation was essential,” Mr. Saur says. “Gil-Mar was looking for automation and was also open-minded on design-for-manufacturing solutions, which helped immensely in our conceptual and engineering phase.”

The Methods solution was a lights-out cell with six FANUC RoboDrill D21LiA5 30-taper, four-axis VMCs; two FANUC robots; and in-feed and out-feed conveyors. Two operators load raw, ductile iron blanks onto in-feed conveyors that feed two operations: op. 10 milling and drilling, and op. 20 contouring and spot-facing. Finished parts are then loaded onto out-feed conveyors for inspection. Production output is 6 minutes per cycle (3 minutes per part, machined two at a time). Typically, 325 part sets are made per 10-hour shift.

It took Methods 14 months to conceptualize, develop, engineer, conduct runoffs and train. “The Methods team did an extraordinary job,” Mr. LaVigne says. “They were dedicated and worked closely with us, making continual process improvements and refinements. It was a very successful project, and for us, a paradigm-shift into automation from dedicated, individual equipment.”

Related Content

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)