Methods Commits to Medical with New Tech Center

The company says the facility is well-positioned to fill healthy demand for CNC machining equipment, service and support among medical manufacturers in the southern United States.

Share

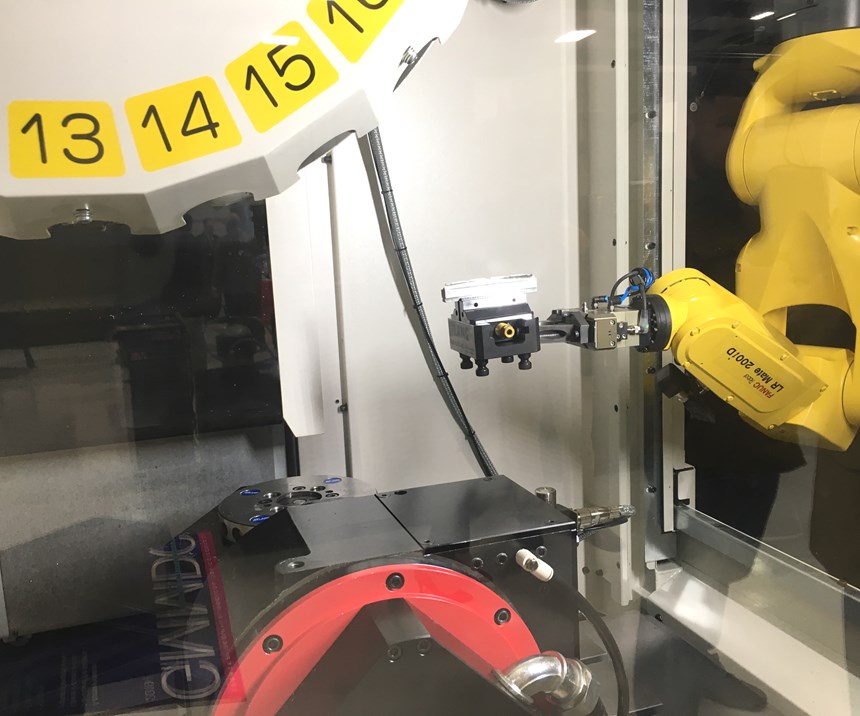

The opening of a new technology center in Memphis, Tennessee, is not only the latest milestone in a big year for Methods Machine Tools, but also a concrete indication of strong demand for CNC machined medical components.

The company has long serviced medical component manufacturers in the southern United States from another location in Charlottesville, North Carolina. Nonetheless, President and CEO Jerry Rex, who presided over a ribbon-cutting ceremony at the new Memphis facility November 14, says it is worth being even closer to a strong base of prospective medical industry customers not only in Memphis, but also in neighboring Alabama, Arkansas, Mississippi and the Florida Panhandle.

As for the strength of the medical market and those who serve it, recent survey data from Gardner Intelligence (the research arm of Modern Machine Shop publisher Gardner Business Media) show that medical manufacturers have experienced strong growth in new orders, production and supplier deliveries. Overall, this data suggest that medical manufacturers are highly likely to close out 2018 in very good condition.

Methods, of course, serves more than just medical manufacturers, and the company’s experience this year— anniversarythits 60—also evidences a strong manufacturing market in general. Headquartered in Sudbury, Massachusetts, the company has expanded its already expansive product line, which ranges from vertical and horizontal machining centers (VMCs and HMCs) to multi-axis turn-mills to EDMs. Thanks to new partnerships, the line now includes EDM drilling machines from Ocean Technologies; HMCs and boring mills from Niigata; and Swiss-type lathes from Tornos.

Related Content

-

Ametek EMC Laser Cutting System Offers Through-Part Cooling

The new laser cutting system offers comprehensive Swiss machining capabilities, as well as through-part cooling and automatic part-handling options.

-

Forkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

-

Grob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

.jpg;maxWidth=300;quality=90)