A Swiss-Type Turning Point

The lessons this shop learned after purchasing its first Swiss-type turning center nearly two decades ago are now being applied to larger multi-spindle and multi-turret lathes for bigger and more complex parts.

Share

Whether it was a big contract, a new machine or technology, a particularly smart hire, or an unexpected epiphany, most machine shop owners can recall a point at which their company embarked on a new course and fundamentally changed in some lasting and remarkable way. For Brendan Slabe, one of those moments came when his company purchased its first CNC Swiss-type lathe.

The experience was documented in the September 1999 issue of this magazine, when Mr. Slabe and his colleagues at Slabe Machine Products were still in the early stages of learning what a multitasking machine could do. Challenges included tackling a new machining process and determining which parts were best suited for a Swiss-type machine. And while the rewards of the investment soon began to accrue, he says, the long-term impact is still resonating on a daily basis in the way the shop goes about many aspects of its work.

“It opened our eyes to the concept of making a part complete in one setup and on one machine,” he says. “Learning to operate and get the most out of a Swiss-type lathe started us down the path toward constantly seeking ways to reduce additional setups, if not eliminate them altogether.”

Just as importantly, the shop realized parts that seemingly looked like they should be produced on a VMC or HMC are actually good candidates for complete machining on Swiss-types with milling capability, even if the part requires minimal or no turning operations. In other words, there’s often no need to worry about tasks like fixturing and indicating on mills. The shop has since added multi-turret, multi-spindle lathes to achieve the same benefit for bigger parts, relying on some of the lessons learned in Swiss machining.

“We’d have gotten into these new technologies and machining processes on our own eventually,” Mr. Slabe says, “but it probably would have taken a lot longer. Buying that first Swiss-type CNC was definitely when we started looking closely at everything we were doing and finding ways to work more efficiently.”

Due Diligence

Based in Willoughby, Ohio, Slabe Machine Products (SMP) was founded in 1939 by Edward Slabe Sr. His son, Edward Slabe Jr., has been president since the mid-1970s, and his grandsons represent the third generation of the family in leadership positions within the company. Christopher is the vice president of operations, and Brendan is the vice president of sales and marketing. SMP is a job shop with a reputation for machining complex parts from materials including stainless steel, nickel alloys, titanium and other metals. “Generally speaking, if you can fit it into a shoebox, we can make it,” Brendan Slabe says.

Throughout the 1990s, Mr. Slabe found himself increasingly drawn to the idea of Swiss-type machining. What he knew was that it operated quite differently than other machining processes in that its sliding headstock allowed barstock to be fed continuously through a guide bushing and past the cutting tool during outer-diameter turning. The close proximity of the cutting tool to the point where the barstock emerges from the guide bushing creates the rigidity that Swiss machining is known for, supporting the workpiece and allowing for deeper, more aggressive cuts. With the cutting tool so close to the point of origin, the barstock is simply too short to allow for deflection. The wealth of axes the Swiss-type machines offer allows parts that are good candidates for the process to be machined in their entirety before the final parting-off cut is made separating the workpiece from the barstock. These appropriate parts include long, thin parts with a length at least four times that of their diameters, such as the firing pin for a gun, or complex medical parts including bone screws and stents. In short, the Swiss philosophy is to use the barstock as the ultimate workholding device.

But there were other considerations for adopting Swiss-type machining as well, beginning with the high cost associated with such a complex machine. As is the case for any business owner, the return on such an investment had to work on paper before a purchase order would be issued. In addition, while conventional lathes can accept whatever diameter of barstock, blank, casting or forging the chuck will allow, the maximum diameter a Swiss-type CNC will machine is determined by the size of its guide bushing, which at most is generally 32 mm. And since most Swiss types can’t make repeat cuts due to their design, the final cut must be made on the first pass, calling for programmers and operators to rethink familiar tool types, paths and techniques.

After comparing the pros and cons, two factors finally tipped the scales in favor of the purchase for SMP. First, with customers placing smaller orders than in days past due to just-in-time purchasing, SMP needed a machine that could produce small lot sizes with a minimum of effort. This could be accomplished on the Swiss-type machine since no fixturing was required, and a variety of part shapes and types can be machined as long as they fit within the diameter of the barstock already loaded in the feeder.

Perhaps equally important was the fact that, once the barstock had been inserted properly into the automatic loader, the machine required little assistance. As long as the barstock kept feeding into the machine, it would continue making parts until it ran out of material.

So the decision was made, and SMP’s first Swiss-type turning center—a Marubeni Citizen - Cincom L20 into which barstock ranging to 20 mm in diameter can be fed—was delivered and installed in 1998.

Seeing Is Believing

Although the shop already had CNC lathes on the floor, they were two-axis machines at most. “You would finish your turning and shut off the machine,” Mr. Slabe recalls, “and if the part needed milling you would take it to a VMC or an HMC. But the Swiss machine really changed things for us. To stand there and watch it make part after part without handling or assistance beyond the initial setup naturally got us to thinking, ‘Wouldn’t it be great if we could machine larger parts this way?’”

Since the L20 could accept barstock with a maximum diameter of 20 mm, SMP now had smaller parts such as valves and thin-walled enclosures covered. But the company also produces parts ranging to 8 inches in diameter and 2 feet in length. Mr. Slabe wanted to find ways to put as many tools on the part as possible, whether large or small, and the Swiss process had set his mental gears in motion. He wanted bigger machines that would allow him to leverage the lessons learned on the Citizen machine to make larger parts.

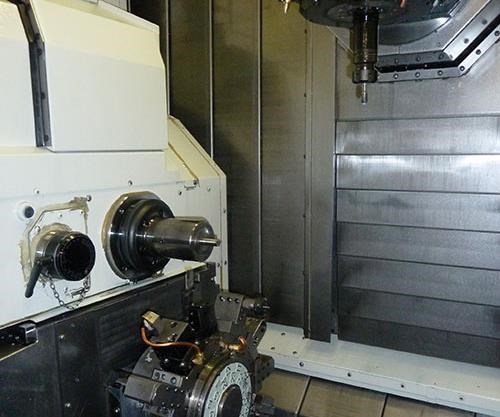

Mr. Slabe found what he was looking for in the Nakamura-Tome series of multitasking machines from Methods Machine Tools of Sudbury, Massachusetts. The dexterity displayed by the Citizen Swiss-type awakened Mr. Slabe to the power of multiple axes, leading to the decision to invest in more multitasking equipment from that point forward, reducing cycle times and lowering the cost per part on which winning bids are based.

Swiss Synergies

As time passed and SMP grew more adept at both the Swiss-type machining process, as well as working with the other multifunction machines, the shop encountered many situations where lessons learned in one area translated directly to the other. Here are a few of its findings:

Backworking: Swiss-type machines have always been known for providing the ability to backwork features on parts once they’ve been cut off from the barstock, but there were only two or three tooling positions on the turret when SMP bought its first Citizen L20 in 1998, which was common at the time. Most Swiss-type machines—Citizens in particular, according to Mr. Slabe—now have a wealth of tooling positions on the turret, so that problem has been rectified as machine design has advanced. However, it was this early experience with Swiss-type machining that made Mr. Slabe want to perform the same types of operations—machining complete on a single setup, with the ability to do any kind of backwork required—on the larger, more-powerful Nakamura multitasking machines he purchased. The technology has advanced on both machine types to the point that he says he can now perform backworking on the entire range of parts his company makes, and in many different ways.

High-pressure coolant: SMP realized the value of a high-pressure coolant system after its first Swiss-type machine was installed. Mr. Slabe says that, due to the small size and light weight of the chips produced by the Swiss machines, the coolant system is basically “sweeping” the chips from the work envelope during the various machining processes. It performs a much more important function on the larger multitasking machines, however, as the 1,000-psi systems are necessary to get under chips, embrittle them and break them off from workpieces made of tough materials such as Inconel. When the coolant nozzle is properly positioned, it decreases tool wear and also makes it more predictable, since the lubricity and temperature of the coolant causes the cutting tools to wear at a more standard rate.

Multi-tool holders: Mr. Slabe is an advocate of multi-tool holders that increase tool capacity in each position on the turret. He uses them wherever possible on both his Swiss-type and multifunction machines. In fact, his various experiments led to the design of a triple-tool holder for his own internal use that is now marketed independently. The device takes the place of a standard OD turning position and adds three ID tool stations. It can be expanded to perform spotting, boring and drilling and can be configured with a through-coolant delivery system.

Deburring: In this area, SMP has reached its goal of making deburring a part of the CNC machining process rather than a secondary, off-machine operation done through tumbling or by hand. This is true with both its Swiss-type and multifunction machines, where a successful tactic involves making a final pass with the tool responsible for machining a particular feature in the first place. As an example, say a hole is drilled through the center of the length of a shaft and the part requires that a series of cross-holes be drilled at a right angle to the through-hole. Burrs will be left along the inner edges of the cross-holes. Mr. Slabe then takes the tool he originally used to drill the through-hole and runs it back through that hole. Since the tool is already positioned exactly where it needs to be, and its wear point is the same as it was after its last pass, deburring is completed with no secondary operations required.

Near-net blanks: Since Swiss-type machines work best with round barstock, Mr. Slabe, much like a sculptor, must figure out how to start with a shape of material as near to finish shape as possible, so that remainder of machining is as minimal, and cost-efficient and competitive, as possible. This exercise led him to rethink the form and origins of the stock he begins with even in his HMCs and VMCs, whether that be a casting, an extrusion, a forging or a pre-machined blank. Minimizing the time it takes to rough out a part by beginning with a near-net shape (an option he cannot pursue on the machines limited to using barstock), he decreases his cost per piece and gets to the final machining more quickly. One way SMP achieves this is by using a powerful 94,000-psi HyperJet waterjet machine from Flow to cut near-net-shape blanks from plate stock. That means less material must be removed by the multi-axis machining center.

When it comes to tooling, SMP tries to use standardized tools whenever possible. The shop has been able to find nearly all the tools it needs for both its Swiss-type and multifunction machines as stock items, which simplifies inventory and eliminates lead times. Mr. Slabe says he doesn’t want to worry about keeping extra custom tools on hand in order to avoid having to wait for a custom tool to be delivered when he needs to get started on a job.

Carry it Forward

Even beyond big benefits like being able to complete a part on a single machine, Swiss-type machining has changed the way SMP approaches smaller things, like making simple objects such as pins that it once purchased from another source. The experience with Swiss-type created the desire to be as efficient and self-sufficient as possible, Mr. Slabe says.

“So now we have a total of seven Swiss-type lathes for smaller parts; a variety of multi-spindle, multi-turret machining centers for parts that go up to 8 inches in diameter; horizontal and vertical machining centers with fifth-axis attachments for both; abrasive waterjet equipment; rapid prototyping machinery; and robots to feed and orientate parts on high-volume applications,” he says. “And much of this came about as a direct result of our experience with Swiss-type machining. That first machine is still running, in fact, so that’s an investment that has definitely paid off.”

Related Content

WFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreIndustry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)