B-Axis Turn/Mills Have Their Place

The additional rotary milling axis on these machines allows them to complete many types of complex parts in a single setup, but these machines have gained a reputation for being difficult to program. Today’s CAM software, however, eases the programming challenge significantly.

Share

Many shops today have begun evaluating the purchase of multi-function turn/mill machines, weighing factors such as cost, capability and productivity gains. These shops must consider what type of turn/mill machine tool best fits their individual needs and the parts they produce. Within the turn/mill machine category is the B-axis machine, a turning machine that includes five-axis milling capabilities. The acquisition of a B-axis machine requires a significant investment in both money and time. B-axis machines are approximately 20 percent higher in price compared to turn/mill machines of similar capacity without B-axis features. However, for shops that produce parts that would benefit from B-axis machining, the productivity gains achieved by B-axis machines more than justify these expenditures.

Shops evaluating the purchase of a B-axis machine should ask these key questions: What does B-axis capability add to a turn/mill machine tool, and what kind of CAM system is needed to take advantage of this capability successfully? The answers are found by analyzing the physical characteristics of B-axis machines, evaluating machine configuration and setup time, and assessing the level of integration of the programming environment.

B-Axis Fundamentals

Methods Machine Tools Inc., a machine tool importer and the exclusive distributor of Nakamura-Tome machine tools in the United States, frequently discusses the fundamentals of a B-axis machine with prospective buyers to be sure they fully understand its capabilities. Methods provides this standard definition to potential customers: The B-axis machine tool combines the turning capabilities of a horizontal/vertical turning machine with the milling and machining capabilities of a five-axis machining center.

Like traditional turn/mill machines, B-axis machine tools provide control over the Z-X (turning) and C (rotary milling) axes. The B-axis head is used as a milling spindle or a turning/boring toolholder, thus enabling the machine to complete all milling and turning with one setup. These machine tools also give users control over the Y-axis for off-center milling operations. However, it is B-axis capability that sets these machines apart. The B axis is defined as rotation about the Y axis, and this fifth axis positioning makes cuts with compound angles possible. B-axis capability gives a machine full support for five-axis index milling and 3D / five-axis simultaneous freeform milling. The B-axis machine is literally one machine doing the work of two because it supports the entire range of milling and turning operations possible, with the advantage of doing it in one setup.

Whole Part, One Setup

B-axis machines increase part accuracy because they hold tighter tolerances between turned and milled features. For example, when a cutting tool body is machined on a B-axis machine, it is significantly easier to maintain geometric tolerances between milling and turning operations. As with traditional turn/mill machines, using one workholding setup eliminates errors that may be introduced by switching a part from a turning to a milling machine. For parts that require the turning and multi-axis milling operations that only B-axis machines are equipped to handle, keeping tight tolerances across multiple datums is especially important for maintaining geometric tolerances between features.

When outfitted with dual spindles, the extended machining range of a B-axis machine enables it to perform both milling and turning operations, on both the front and back of the workpiece. Each spindle (main and sub) acts as a workpiece holder, allowing simultaneous five-axis cutting on either the front or back of the part, thereby completing the entire part in one setup. A job that previously required four setups (front-turn, back-turn, front-mill, back-mill) can be reduced to one setup on a machine with B-axis capability.

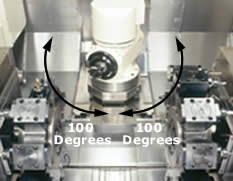

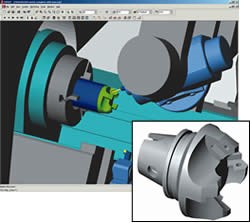

A multi-spindle B-axis machine outfitted with a lower turret further increases capacity for producing parts in a single setup. See Figure 1. In this configuration, the B-axis head operates at the same time other turret-based cutting tools are being used on the opposite spindle, enabling synchronized simultaneous machining. In other words, cutting occurs on both the front and back of the part at the same time.

What B-Axis Parts Look Like

Cylindrical parts with milled features at compound angles or on multiple faces are surprisingly common. Shops serving the heavy equipment and oil service industries, producing parts that demand precise five-axis contouring and finishing, often use B-axis machines to manufacture shafts with slots, grooves and cutouts at compound angles. Shops also use B-axis machines for intricate, multi-faced parts, such as cutting tool bodies and holders. See Figure 2.

The size of B-axis parts can vary greatly. Parts as small as a 0.04-inch diameter watch gear or as large as a 20-inch diameter metal casting can benefit from B-axis machining.

To accommodate the different machining needs of its customers, Methods Machine Tools offers two models of Nakamura Tome machine tools equipped with a B axis. The STW-40 model with standard 40-station automatic tool changer is designed to handle large, heavy parts such as castings and forgings and can accommodate work pieces up to 17 inches in diameter. However, in response to customer demand, Methods now offers a smaller model B-axis machine, the NTJ (B-axis turret). This model is roughly half the weight and size of the STW-40, has the advantage of taking up less floor space, and is easier to maintain and run than its larger counterpart. The NTJ is best used for the machining of smaller B-axis parts, such as arthroscopic tools, which don’t exceed 8-inch diameters.

Both models are equipped with barfeed capability, enabling shops to feed stock into the machine tool in a continuous stream and then perform B-axis cutting, if needed, on part features with compound angles. For example, a shop producing large volumes of watch bodies could use this type of machine for uninterrupted machining. When evaluating parts and barfeed options, shops should consider the size of the stock. While a larger B-axis machine equipped with barfeed can handle larger bar stock, it is not always practical to feed stock of this magnitude into a machine tool. Because bar stock tends to be long (a length of 12 feet is not uncommon), it may prove to be too heavy for a person or robot to lift. Large stock is also difficult to cut when it comes time to part off the slug.

In addition, shops should also consider the “unexpected” parts that don’t necessarily have B-axis features (features at compound angles and/or on multiple faces) but that still require both milling and turning work. For example, a company may machine a subset of hydraulic components that requires B-axis machining, but find a majority of its jobs require both traditional milling and turning operations. For this type of shop, purchasing a B-axis machine will enable the shop to meet the entire range of its turn/mill machining needs.

Easier Programming

Once a shop has decided that a B-axis machine fits its needs and the parts it produces, primary concern shifts to ensuring that CNC programmers have the CAM tools capable of programming these machines. Effective CAM software enables shops to take full advantage of the capabilities of B-axis machines by providing tools that create, optimize and verify CNC programs efficiently. Watching a B-axis machine in action (particularly for the first time) can be quite intimidating because of its complex configuration, simultaneous machining and non-perpendicular multi-axis tool movements. Therefore, it is essential that a CAM system give programmers full control over all machine movements. This control eases the challenge of programming these complex machines, and the availability of such software should encourage more shops to consider the productivity advantages of such equipment.

When CAM software developer DP Technology began to study the programming considerations for workpieces produced on B-axis machines, it recognized that a system using one, fully integrated mill/turn programming environment would simplify the programming of these machines and provide shops with the flexibility they need to program B-axis parts efficiently and accurately. Essentially, an integrated programming environment means that a shop would not have to do the turning portion of the part in one software application and the milling portion of the part in another software application and then try to coordinate the two effectively.

For this reason, the company developed the Esprit SolidMillTurn product line. Released in March 2003, this software offers a suite of machining cycles for two- to five-axis milling, including three-axis and simultaneous five-axis 3D multi-surface/solid machining, as well as support for turning cycles such as facing, boring, grooving and threading. The software gives programmers the flexibility to use milling and turning cycles in any combination in one session on a single workpiece: on the front or back of the part, with the primary or secondary spindle, with the upper B-axis head or lower turret.

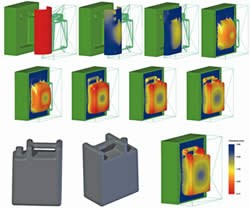

As part of this software, one programming tool that is especially important for programming B-axis machines is Work Planes. Each part feature is automatically assigned to the most appropriate Work Plane, thus simplifying the programming of parts for B-axis machining. Work Planes define the orientation of the C and B axes, making drilling and milling features that are at compound angles (B-axis features) easy. See Figure 3. For example, instead of programming a simultaneous X- and Z-axis move to drill a hole at an angle, programmers can use Work Planes to define the angles of the C and B axes, thus automatically rotating the Z-X coordinate system and requiring the programmers to specify only a single Z-axis move. In actuality, the machine will move both the X and Y axes to produce the hole. Work Planes enable users to establish “local coordinate systems” which simplify the actual G-code used to produce a given feature and make it easier for the operator to understand.

Software tools that synchronize and optimize machining operations through a single interface are helpful for organizing the turn/mill program. DP Technology believes that an effective synchronization tool fully integrates all machining, not only offering a combined display listing both milling and turning operations and their associated cycle times, but also adapting its view to meet the number of turrets, heads or spindles supported by the machine. Logistically this simplifies programming by only requiring users to go to one location to find out how the part is being machined. The ability to move, copy, edit and synchronize operations through a single interface also helps make optimizing the part program easier.

Time studies that automatically calculate cycle time used in combination with a comprehensive simulation and verification tool are extremely valuable in B-axis machining where tool crashes are a constant concern for shops. Shops using B-axis machines will find it very useful to be able to program a series of mill and turn operations, optimize the cycle times, and then simulate these operations at any point in the programming process to verify there are no tool collisions.

To verify CNC programs effectively, it is helpful if the simulation truly mimics the machine operation. For example, Esprit’s Machine Setup provides an interface for shops to define the configuration and number of turrets and spindles of the shop’s specific machines to ensure accurate simulation. Further, to provide effective programming for B-axis machining, this CAM system shows the entire part on screen along with the key moving elements of the machine tool (spindles, turrets, B-axis heads, tooling), not just sections of it, in order to protect against potential crashes, especially during synchronized simultaneous machining or transferring of the part from the main to subspindle. See Figure 4. Once the tool path is generated and verified, the post-processor produces the G-code program for all milling and turning operations. This is an advantage over software requiring the user to post-process turning and milling tool paths separately and then combine them into one program to download to the shop floor.

Productivity Partners

In recent years machine tool manufacturers and CAM software developers have begun forging relationships to meet the needs of shops using B-axis machines. The goal is to win wider acceptance of these machines for the appropriate applications by overcoming the user’s resistance based on the perception that these machines are difficult to program. For example, Methods Machine Tools has successfully worked with the Esprit CAM system and its application team in a partnership that has produced an effective programming solution for its B-axis customers.

This cooperation between machine tool dealer and CAM software developer offers significant benefits for shops purchasing B-axis machines because the solution offered saves a significant amount of software setup time, enabling shops to immediately take advantage of the productivity these machines offer. For example, customers are assured of having a working postprocessor because the two suppliers have developed the postprocessors together and have tested them on sample B-axis parts. Further, the configuration of particular machines has already been defined in the CAM system’s Machine Setup and is available right away.

Compelling

The potential of a B-axis machine for increasing productivity and producing multi-faceted parts in a single setup is a compelling reason for shops to invest the time and money in this type of turn/mill machine tools. Shops that hesitate over concern about the programming challenge have no reason to do so. Partnerships between knowledgeable machine tool dealers and experienced CAM providers ensure that a new B-axis machine will reach its potential because it has the necessary programming capability in place to maximize productivity.

About the authors: Chuck Mathews is Vice President of DP Technology. Eric Stoveland is an application engineer at Methods West Machine Tool Inc. in Fountain Valley, California.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreRead Next

Programming Multi-Axis Lathes

You're going to need more than the CAM program you're currently using for your standard CNC lathes and mills.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)