Adding Context to Advanced Milling

For all its focus on machines, cutters, parameters and tool paths, an expo hosted by Methods Machine Tools demonstrated that competitive hard milling increasingly requires looking beyond the workzone and even beyond traditional machining.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreFor job shops and other manufacturers dealing in small lots of varied work, “The easiest thing to do is cutting the part.”

That was one of Dave Lucius’s key messages to an assembled group of manufacturers at Methods Machine Tools’ Advanced Milling and High Speed Machining Expo in Sudbury, Massachusetts, last week. The company’s VP of national sales certainly didn’t intend to detract from the event’s laser-focus on efficiently milling hard, difficult materials like titanium and Inconel that are increasingly common in the aerospace and die/mold industries. Rather, Mr. Lucius’s point was that even the utmost familiarity and comfort with what’s happening inside the machine workzone is no longer enough for American manufacturing competitiveness. Particularly for shops with a high-mix, low-volume workload, automation of machines with more than three axes is the future of hard milling, he says.

The reason why is direct labor costs. To demonstrate, Mr. Lucius presented a spreadsheet comparing a host of figures associated with investing in a single five-axis machining center with a multi-pallet system versus multiple, single-pallet five-axis machining centers. Even adjusting various numbers to purposely favor the multiple machine strategy, the multi-pallet system always came out on top (assuming enough work to fill capacity). In some cases, multiple single-pallet machines produced greater revenues. Nonetheless, the comparatively less labor associated with fewer spindles and more pallets always drove profits higher.

Even with a commitment to this kind of production, shops should have a well thought out plan before making any moves, he says. Key things to consider include housekeeping and organization (do you have a 5S program?); total quality management integration (will there be an inspection bottleneck, or will the machine be starved?); a setup reduction plan (what kind of pallet system, how many pallets?); implementing a Kanban or other system to help keep work flowing; and, finally, the presence of “champions”—staff members with the expertise and the drive to make all this work.

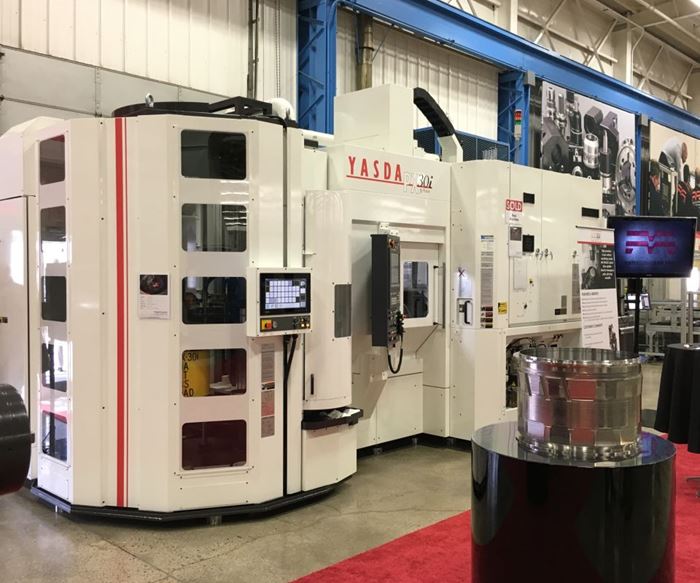

The event's focus on hard milling made Methods' Yasda-brand machines the natural stars. However, the concepts described above apply just as readily regardless of the machines' brand or capability. With multiple brands of milling as well as other types of equipment, Methods is positioned well to demonstrate not just that, but also how other technologies can affect milling competitiveness.

Outside of the aforementioned automation systems, Exhibit A was additive manufacturing. Methods 3D, a division of the business formed by a partnership with 3D Systems, offers machines that build parts layer-by-layer from beds of metal powder. Although this technology is segregated from the rest at the facility's dedicated additive lab (one of seven at Methods technology centers around the country) not discussing it would have made the milling event seem incomplete, at least in hindsight. After all, the more additive technology advances, the greater its potential to act not as an alternative to advanced milling, but as a complement to it.

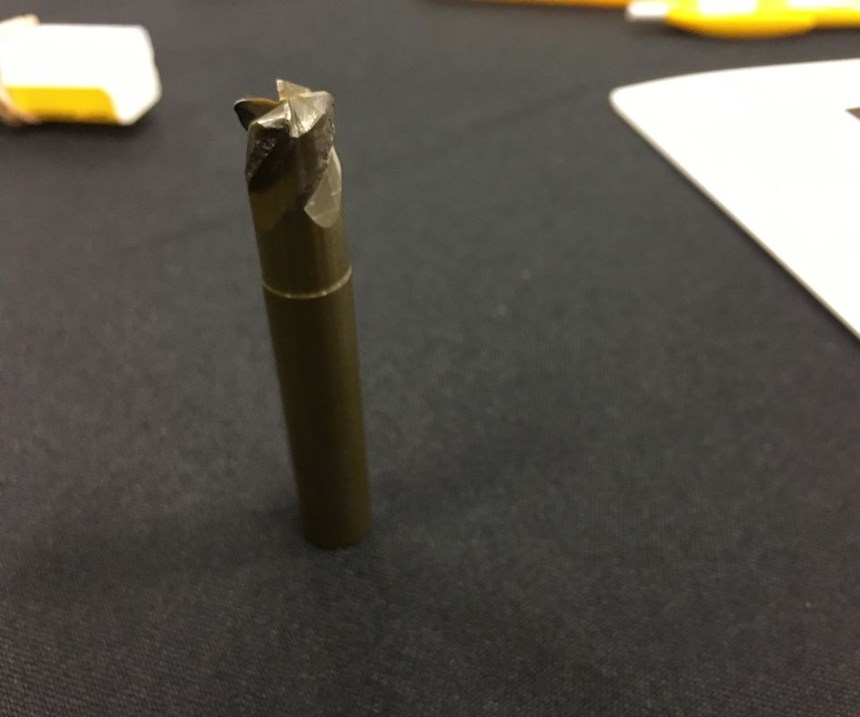

Scroll through the picture gallery above for a couple of brief examples, as well as a few tidbits of hard milling wisdom that can be potentially beneficial in any context.

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More