Job Shop Uses 3D Wire Bending and CNC Machining To Find Its Niche

Marshall Manufacturing melds CNC machining and 3D bending to create intricate medical components from small-diameter barstock and tubing. Customer needs spurred the shop to carve out what has become a successful medical-manufacturing niche.

Share

By and large, shops don’t shape themselves; customers shape shops. That is, customer needs drive decisions about the equipment, capabilities and processes shops bring in-house. As a result, an increasing number of them are looking beyond conventional subtractive machining processes to alternate manufacturing technologies that complement their chip-making equipment. After all, the goal is to deliver whatever product the customer requires in the quickest, most cost-effective way possible.

Marshall Manufacturing is a good example of this trend. For this Minneapolis, Minnesota shop, a medical customer’s need for accurately machined and helically bent wire components spurred the development of a proprietary 3D bending process that works hand-in-hand with the shop’s advanced machining equipment. The process Marshall Manufacturing engineered enables it to machine key features into straight, small-diameter barstock or tubing using Swiss-type lathes or wire EDM units. It then can accurately bend the parts to the correct profile on its modified CNC bending machine. (Traditionally, this procedure is reversed: bending is performed first and machined features are added later, making machining much more challenging.) The shop’s more efficient and effective approach not only enables features to be precisely machined anywhere along the barstock prior to bending, but also ensures that those features end up in their proper locations after the complex bending operations.

A New Path

Marshall Manufacturing didn’t set out to be a specialist in both machining and 3D bending for wire and tubular medical devices. The company began in the early 1950s as a supplier of precision turned parts largely for automotive and hydraulic applications. Today, the 40-person machining business operates in a 23,000-square-foot, air conditioned facility with 60 percent of its work dedicated to the medical industry and 40 percent geared toward filtration equipment (primarily machining plastic core tubes for filtration cartridges). The shop does some general machining, too. It can process numerous materials including stainless steel, titanium, aluminum, brass, bronze, copper and a variety of plastics. It is certified to both ISO 9001:2008 and ISO 13485:2003 standards. Achieving the latter standard has been key to growing the medical side of its business.

That customer’s need for bending work years ago proved to be the game-changer for Marshall Manufacturing. Initially, the customer required machined parts with relatively simple 2D bends. The shop was able to handle that work in-house without too much trouble. After that, though, it was approached to manufacture parts that required more complex helical bends. Having no experience with 3D bending, Marshall Manufacturing searched for an outside vendor to take on that work. It turns out that the only vendor willing to try this complex bending job simply couldn’t handle it, so the shop decided to create a 3D bending process of its own. After successfully developing its manual bending process, however, production volumes for this work increased. At that point it became readily apparent that the shop needed a more efficient CNC bending technique to keep pace with growing demand.

Machining, Then Bending

Many of the bent medical components the shop manufactures are partially overmolded with a plastic handle. One example is known as introducers, which are components used by surgeons to position organ-supportive slings during minimally invasive incontinence procedures. Depending on the device manufacturer, the geometries of both ends of these devices differ (they might be straight, wedge-shaped, tapered or slotted).

Most machining for these wire components is accomplished using Swiss-type lathes. The shop has nine such machines, but the bulk of the work is performed on its four L20 Swiss-types from Marubeni Citizen-Cincom (Allendale, New Jersey). These seven-axis machines accommodate barstock diameters ranging from 0.1 to 0.75 inch and include Marubeni Citizen-Cincom’s own CAV20-IS bar feeding system. Although the shop has had bar feeding snafus with its other Swiss-types, it says this hasn’t been a problem with the L20s because the bar feed system is designed to work specifically with those machines. Such reliability as well as programming simplicity are big reasons why the shop has since settled on Marubeni Citizen-Cincom as its Swiss-type supplier.

Each L20 machine has a main spindle and a secondary spindle that share machining operations. The main spindle offers maximum rotational speed of 10,000 rpm while the secondary spindle offers 8,000 rpm. With their signature supportive guide bushing design, these machines are particularly effective for the long, small-diameter barstock material Marshall Manufacturing machines for the introducers. That’s because the guide bushing provides workpiece support at the point of the cut, minimizing workpiece deflection and vibration. Plus, in addition to milling, drilling and turning, these multifunction machines can perform broaching, honing, knurling, burnishing, hobbing, thread whirling and thread rolling. This often eliminates the need for secondary operations on another machine.

The wire components the shop produces—many of them made from stainless steel—begin as 12-foot lengths of centerless-ground barstock. Precision barstock is nearly always used with Swiss-type turning centers to ensure that the material can be fed through the guide bushing without sticking. Ground barstock offers diameter accuracy to 0.0002 inch. Such precision is important when a plastic handle is to be molded over the component to ensure proper shut-off on the part during molding. Similarly, the accuracy of drilled cross holes is important because the holes are sometimes used to locate the part on a pin inside a mold. The same is true for flats and other features that may be used to help orient the part prior to the CNC bending operation.

The four L20 Swiss-types are located together in a cell. Each has a gripper that delivers completed components out of the machine. The parts are delivered down a chute and collected when the machines run in normal mode. For high-volume jobs, however, the machines can serve as an unmanned production cell. A Fanuc gantry robot within the cell picks completed parts from the L20s and delivers them to an ultrasonic cleaning station. This station includes its own small Fanuc robot, which takes each part through three separate ultrasonic baths to remove chips and cutting fluid. After the cleaning and rinse cycles, parts are blown dry. The gantry robot’s jaws are also cleaned and blown dry prior to delivering finished parts into a Tesa Scan 50 non-contact measuring system for final inspection. This device can measure length, diameter, angles, radii and other features on cylindrically symmetric components.

Wire EDM is commonly used to produce tip features in tubular stock. The shop has two Fanuc Robocut wire EDM units with automatic wire feed (these machines are available from Methods Machine Tools). System 3R clamping components allow quick relocation of fixtures on the machine’s table. That way, an operator can set up a job on one fixture while the machine runs another job. The shop stacks multiple tubes to be machined simultaneously. Slots created via wire EDM can be held to 0.0002 inch.

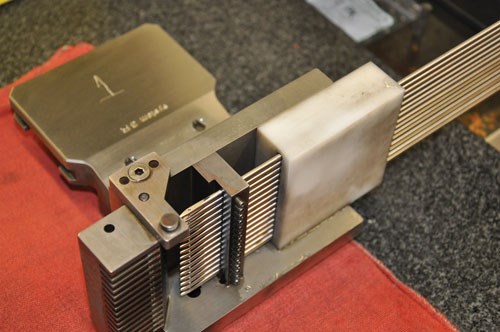

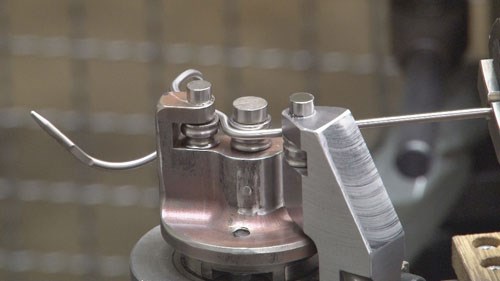

Once machining is completed, the tubing or barstock is delivered to the shop’s 3D CNC bending machine. The shop (which won’t disclose the brand of the bending machine it uses) has developed an innovative combination of tooling and automation for unattended operation.

The eight-axis bending machine accommodates tubing diameters ranging from 0.096 to 0.375 inch and barstock diameters from 0.08 to 0.2 inch. In operation, the machine’s actuator arm picks up a machined length of barstock from a staging magazine, while a sensor ensures the material is properly oriented according to a machined feature. A guide helps send the wire through the machine’s three mandrels. The 3D bending operation is accomplished via choreographed movement of the mandrels and rotating actuator arm. Programming is done at the machine using shop-developed macros to fine-tune basic bending programs.

Machining for Inspection

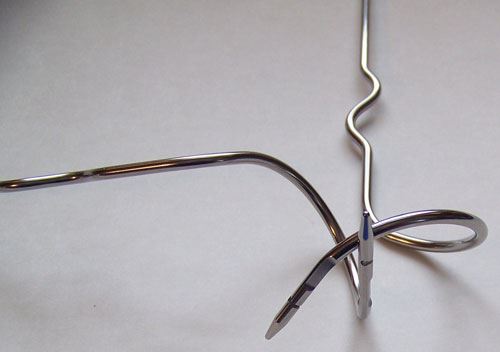

Marshall Manufacturing has a number of measuring devices. However, machining plays a role in bent-part inspection. The shop machines go/no-go gages like the ones on the previous page for many of the 2D and 3D medical components it manufactures. The parts drop into the gage and locate off of a part feature, typically a tip, flat or shank. A properly bent part will not contact the gage’s machined profile walls or exceed the height of the machined channel. The shop performs 100-percent inspection of its bent components. This is important because spring-back associated with the bending process can differ based on the material. This also enables the shop to detect bends that are trending out of tolerance so offsets can be made at the bender’s CNC to compensate.

The shop typically machines three gages—one for its own use, a second for its molding vendor to check parts prior to molding handles, and a third for its customer. Tolerances for bends are based on design requirements. Bend consistency is very important for these devices. For some parts with basic 2D bends, the shop will use a simple yet effective paper printout outlining the part’s allowable limits to the bend profile.

Looking Ahead

Proficiency in 3D CNC bending has the shop looking outside the medical industry for appropriate applications that require bent wire or tubular components with accurately machined features. The shop is also hoping to capitalize more on the multifunction machining capabilities and precision its Swiss-types offer. In particular, it is investigating cannulated bonescrew work using thread whirling. Its goal is to grow its medical work to represent 75 percent of its total business.

Related Content

Lyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More