BIG DAISHOWA Inc.

2600 Huntington Blvd.

Hoffman Estates, IL 60192 US

888-866-5776 | 224-770-2999

bigdaishowa@us.bigdaishowa.com

bigdaishowa.com/en

About BIG DAISHOWA Inc.

Higher Performance. Guaranteed.

You don’t compromise and neither will we. BIG DAISHOWA’s mission is to find the best tooling solution for you and deliver it with a personal commitment of efficient and measurable performance improvements.

Premium tooling is critical to top-level production performance. BIG DAISHOWA manufactures high-performance, high-tolerance tooling. The result is an all-star line-up of products engineered to exacting standards and manufactured with materials and craftsmanship that enable superior performance.

Not every shop requires extreme accuracy or total efficiency. But for those whose challenge is to manufacture with greater responsibility and accuracy and to find products and processes to improve the efficiency of your applications, call us. We want to work with you.

As a member of the BIG DAISHOWA Group (Osaka, Japan), BIG DAISHOWA Inc. has grown into a recognized global tooling provider, with manufacturing facilities in North America, Japan and Switzerland. In addition, BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system.

IS THIS YOUR COMPANY?

Video Gallery

Why BIG DAISHOWA Collet Chucks? Low runout, high repeatability.

When it comes to choosing a collet chuck, you have a range of options. But not all are created equal. BIG DAISHOWA has ...

Tips for Boring Tool Selection

Are you setting yourself up for success when it comes to boring tool selection? In this video, Matt Tegelman, Senior Product ...

High-Speed Machining: Expert Guide for CNC Tooling Solutions

Join Nick Jew, R&D Engineer at BIG DAISHOWA, as he breaks down everything you need to know about high-speed machining ...

How to Evaluate Precision Tooling for CNC Machining

Are you looking for tooling options that can help unlock superior performance and results? Pull up a chair as our resident tooling ...

As Seen On Modern Machine Shop

BIG DAISHOWA Inc. Supplies the Following Products

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Angle & Sub Plates

- Arbors (for Cutters)

- Boring Tools

- Boring Tools & Heads for Machining Centers

- Boring Tools for Turning Machines

- Chamfering Tools

- Chuck Jaws & Collets

- Chucks, Collet Type (for Workholding)

- Chucks, Index

- Chucks, Jaw Type

- Chucks, Precision

- Chucks, Special

- Clamps & Fixturing Devices

- Collets for Toolholding

- Collets for Workholding

- Collets, Solid & Master

- Counterbores/Countersinks

- Couplings

- Drill Chucks

- Drilling Attachments

- Drills

- End Mills

- Facing Tools/Heads

- Fixturing Systems

- Grooving Tools

- Inserts, Indexable (Carbide, etc.) & Tool Inserts

- Maintenance & Repair

- Milling Cutters

- Milling Heads/Attachments

- Pedestal Type Fixtures & Tombstone Blocks

- Probes, Electromechanical

- Reamers

- Retention Knobs

- Robot Tooling/Grippers

- Spindles

- Tap Drivers & Attachments

- Tool Blanks

- Tool Condition Monitoring Systems

- Tool Conditioning Equipment

- Tool Presetters

- Tool Presetting Equipment

- Tool Repair, Coating & Treatment Services

- Tool Storage & Handling Systems

- Toolholders

- Tooling Systems, Modular and/or Quick-Change

- Vises & Vise Jaws

- Workholding, Custom

Trade Names Offered by BIG DAISHOWA Inc.

- mptec

- Unilock

- Tekusa

- Tool Pro

- Sphinx

- BIG DAISHOWA

- Speroni

Editorial, News, and Products

-

Big Daishowa Cutting Tools Enable High-Efficiency Machining

IMTS 2024: Big Daishowa highlights its Big-Plus BBT series of diameter cutting tools, with extended length and optimized performance for grooving and shoulder milling.

-

Big Daishowa Opens New Facility To Expand Capacity

The 49,500-square-meter plant in Awaji, Japan is designed to meet production needs and accommodate future growth.

-

Big Daishowa Announces New Personnel Appointments

Edgar Argueta, Glen James and Tom Burley join the company in various sales roles to support the company’s strategic initiatives.

-

Big Daishowa Tool Program Equips Schools

The company’s 2023 Tools for Schools program provided $23,300 in tooling certificates for local high schools, vocational schools and colleges.

-

Big Daishowa Milling Cutters Provide Versatile Operation

The company has expanded its lineup of Fullcut Mill FCM tools to include larger diameters and additional lengths.

-

Big Daishowa Enhances Boring Tools With Vibration Damping

Smart Damper technology shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration.

-

4 Ways to Stop a Cycle to Allow Operator Intervention

Completely automatic operation should always be the goal, but there are situations that require operator intervention during the CNC cycle.

-

Big Daishowa Toolholder Increases Precision for Lathes

The Big Capto C3 series provides higher rigidity to minimize vibrations and movement during cutting, improving accuracy and efficiency.

-

Manufacturing Technology and Training in Europe

NTMA’s European Tech Tour exposed attendees to the latest technology and traditional training methods used by European manufacturers.

-

Big Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

-

Big Daishowa Enables Customers to Give Back to Local Schools

A selected school receives a certificate valued at 20% of qualifying orders and redeemable for any Big Daishowa product.

-

Grooving Attachment Streamlines Operation by 75%

A grooving attachment enabled Keselowski Advanced Manufacturing to reduce cycle times by over 45 minutes on a high-value, high-nickel part feature.

-

Big Daishowa Incentive Supports Manufacturing Training Programs

Through the end of the year, Big Daishowa will donate a tooling certificate valued at 20% of every order from an NTMA member company to the buyer’s school of choice.

-

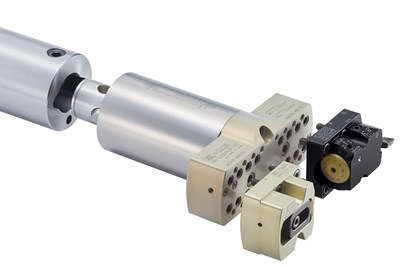

Fully Automatic Boring Head Performs Without Human Operator

EWA, a fully automatic boring head from Big Daishowa, performs closed-loop boring operations with no human operator.

-

Big Daishowa Upgrades Base Master Touch Sensors

Enhancements include an LED indicator for full series and a side handle for maneuverability on the Master Mini model.

-

Big Daishowa Promotes Michael Herman to VP Sales

Herman brings 40 years of experience, including 10 with the company. He will oversee the company’s sales team and support its distribution network.

-

Putting Production on Repeat with Machine Tool Automation

Cobots and automation advances have spurred tooling and workholding innovations like Big Daishowa’s zero-point workholding system and EWA fine boring head.

-

Workholding 101

No universal workholding solution exists, so machine shop employees should have a basic understanding of multiple ways they can secure workpieces.

-

Agile Tooling Prepares Shop for Machining Spaceflight Parts

Big Daishowa’s angle head and milling chucks have enabled Baker Manufacturing to keep up with the tight turnarounds and mystery metals of Blue Origin.

-

4 Ways “Tag and Track” Technology Keeps Data Chains Intact

Scannable images and tags inextricably link relevant information with workpieces, cutting tools and other physical assets.

-

Big Kaiser Changes Name to Big Daishowa

Big Kaiser, member of the Big Daishowa group, to change name to Big Daishowa; the name change will not affect product lines or operations.

-

Big Kaiser Introduces Heavy-Duty Dial Indicator Stands

The company says the new stands have 220-lb-capacity (100-kg-capacity) magnets, rotate 360 degrees and can use DGH 3 or 4 adaptors.

-

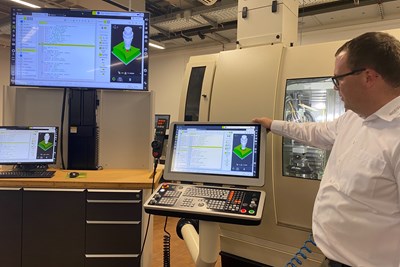

Tool Presetting Identifies and Isolates Costly Problems

Speroni’s Futura CNC presetter enabled Cogitic to diagnose runout and wear problems with its tooling before running the tools on its machines, saving time and expensive material.

-

Big Kaiser Offers Longer, Larger Mill Holders

The company has expanded its line of Smart Damper-equipped face mill holders to offer its longest, largest milling tools yet.

-

Big Kaiser Expands Hydraulic Chuck Offering for Swiss Lathes

Company adds inch-sized, standard-type chucks and new F and R type chucks to its offerings for Swiss lathes.

-

Big Kaiser Donates to National Robotics League

Big Kaiser has donated $6,275 to the National Robotics League, raising the money through a 2% match from NTMA member purchases in 2020's last two months. This is the OEM’s fifth annual contribution.

-

Big Kaiser Releases Smallest Yet EWN Boring Heads

Big Kaiser has debuted two smaller sizes of its EWN Smart Damper precision boring heads, which it says eliminate vibration in deep-hole finish boring.

-

Choosing Workholding to Meet Machining Challenges

When it comes to workholding, shops can choose from options that can provide flexibility, help increase throughput and enable five-axis machining.

-

Big Kaiser Introduces LiveChat Services

Big Kaiser has introduced a LiveChat service to its website, providing real-time chat support during normal business hours and an after-hours message service.

-

Cutting Tool Technology Aids Lights-Out Machining Applications

These features can help improve cutting tool stability, standardize cutting performance and extend tool life, enabling shops to confidently run unattended shifts.

-

BIG KAISER Introduces Sphinx's High-Performance Nirox Drill

BIG KAISER has introduced Sphinx’s Nirox high-performance drill, which specializes in use cases with low cutting speeds in unstable environments.

-

Big Kaiser Promotes Jack Burley to President and COO

Big Kaiser is promoting current sales and engineering VP Jack Burley to president and chief operating officer.

-

Big Kaiser Raising Funds for NRL Through December

Big Kaiser plans to donate 2% of NTMA member orders to the National Robotics League from November 1 to December 31.

-

Cutting Data, Indexable Inserts Optimize Fine Boring

By using digital technology and optimized indexable inserts from Big Kaiser, Schmauser Müller Metalltechnik has increased its process reliability and efficiency in fine boring applications as well as improved tool life.

-

Big Kaiser's Speroni SPI Streamlines Data Transfer

Big Kaiser’s Speroni SPI for tool presetting speeds up tool measurement input while reducing opportunities for user error.

-

Standardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

-

Big Kaiser's Noventa Optimizes Chamfering Cycle Times

Big Kaiser’s new Noventa from Sphinx milling cutter lineup optimizes front-and-back chamfering and deburring, improving cycle time, tool life, surface quality and product finish.

-

Workholding Considerations for Five-Axis Machining

Five-axis workholding isn’t just about applying technology; it’s also about applying a different mindset.

-

Big Kaiser's HDC Jet-Through Toolholder Improves Five-Axis Surface Finish

Big Kaiser has expanded its HDC jet-through hydraulic chuck line to include the BCV interface and additional inch sizes.

-

Big Kaiser Enables Buyers to Find, Purchase Demo Equipment

“These are like dealer-certified pre-owned cars,” says Big Kaiser’s VP of sales and engineering.

-

Big Kaiser's FLM, ELM Chipbreakers Designed for Cutting Long-Chipping Metals

Big Kaiser’s FLM and ELM insert chipbreakers are designed to improve surface finish in long-chipping materials.

-

A Job Shop Approach to Automation

Through patient research and smart investing, this job shop has slowly grown its capabilities and is moving toward lights-out manufacturing for prototype work.

-

Big Kaiser Switches to Greener Materials, Packaging

The new steel uses a Bismuth composite instead of lead, making it more environmentally friendly.

-

Big Kaiser's Fullcut Mill Contact Grips Feature Threaded Coupling System

Big Kaiser’s Fullcut mill contact grip endmill permits easy indexing of cutter heads while maintaining rigidity and accuracy.

-

Setting Up and Operating Fine Boring Heads Just Got a Lot Easier

The combination of a digital boring head integrated with tool data software dramatically reduces the time required to set up a fine boring head. And still more IIOT-enabled advancements are just around the corner that will finally automate many boring operations.

-

Big Kaiser's EWA Enables Handling of Multiple Bore Sizes

EMO 2019: Big Kaiser’s EWA is a fully automated, integrated machine tool system.

-

Big Kaiser’s Speroni STP Essentia Enables Offline Tool Measurement

Westec 2019: Big Kaiser’s Speroni STP Essentia tool presetting and measuring system performs measurements next to machine tools.

-

Lollipop from Sphinx Adds Undercutting Tool to Big Kaiser's End Mill Lineup

Big Kaiser introduces the Lollipop end mill from Sphinx, designed for machining undercuts, deburring and multi-axis machining.

-

Big Kaiser's Twin Cutter Boring Tools Make Larger Holes

Big Kaiser’s 319SW Twin Cutter series of boring heads can make holes ranging from 0.787" to 8.000".

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

-

Big Kaiser's Mini Indexable Boring Bar Meets Medical, Aerospace Needs

The 4-mm Mini indexable boring bar from Big Kaiser is designed to be ideal for small-component machining.

-

Modular Stabilizer System Adjusts to Odd-Shaped Parts

Eastec 2019: Big Kaiser’s Unilock stabilizer system provides lateral support for tall parts during machining, welding or assembly processes and enables the transfer of loads down to the table or base.

-

Modular Workpiece Stabilizer System Adjusts to Tall Parts

Big Kaiser’s modular, zero-point Unilock stabilizer system provides lateral support for tall parts during machining, welding or assembly processes and enables the transfer of loads down to the table or base.

-

January 2019 Product Spotlight: Measurement and Inspection

This month’s Modern Equipment Review Spotlight focuses on equipment used for measuring and inspection, including gaging and tool setting.

-

Palletization Slashes Setup Time for Racing Shop

Whereas his predecessor had left Big Kaiser’s Unilock pallets in the corner, Charlie Mitchell of Andretti Autosport saw that they could help him reduce setup time on his milling machines in an environment where quick turnaround is essential.

-

Jet Coolant Nut Directs Fluid to Cutting Edge in Micromachining

Big Kaiser’s Mega micro coolant nut is said to provide precise coolant supply to micro cutting tools applications at high speeds when using the Mega micro chuck 6S.

-

Expanded Toolholder Range Includes C4 Size

Big Kaiser has expanded its range of Big Capto toolholders with the C4 size.

-

Swiss-Type Hydraulic Chucks Clamp in Three Turns

Big Kaiser introduces hydraulic chucks for Swiss-type lathes, which is said to be the first improvement to this technology in more than 30 years.

-

Gage Provides At-a-Glance Inspection of Machine Spindle Tapers

Big Kaiser’s Dyna Contact taper gage enables at-a-glance inspection of machine spindle tapers.

-

Multi-Function Cutter Prevents Chipping in Spot Drilling

Big Kaiser has introduced two versions of the C-Centering Cutter, a multifunction cutter capable of spot drilling, centering and chamfering.

-

Big Kaiser Promotes New Website

Big Kaiser has launched an updated website ahead of IMTS 2018.

-

Shop Works to get the Most Out of Its Five-Axis Capabilities

Vertical machining centers with rotary tables helped this Indiana job shop set itself apart, but specific machine features and additional equipment have helped it use them more efficiently to grow its business.

-

Fixture Notifies User of Proper Torque Value Via Audible Buzzer

IMTS 2018: Big Kaiser’s Torque Fit is a tightening fixture for collet chucks with an integrated torque measuring system.

-

NTMA Members Spotlight Shop Additions

While traveling with some members of the National Tooling and Machining Association, a few highlighted recent improvement efforts from which their operations have benefited a good deal.

-

Machining Technology Trip to Japan

A recent trip with NTMA members to Okuma and Big Daishowa manufacturing facilities provided the opportunity to learn about their in-house production capabilities and new machining technology offerings.

-

Big Kaiser Launches Redesigned Website

Big Kaiser has launched a redesigned website to improve the online customer experience.

-

Using Data to Do Better in Manufacturing

Although the Smart Manufacturing Experience 2018 event in Boston may not have provided a simple, clear definition of “smart manufacturing,” it did provide a broad experience of what smart manufacturing can be like.

-

Big Kaiser Celebrates 70th Anniversary

The company, which was founded in 1948 in Switzerland, has continued its founder’s mission of developing cutting tools that keep up with machine tool technology.

-

Super-Slim Toolholder Enables Deep Clearance

Big Kaiser has released the HDC Straight Shank slim toolholder, designed to reach into confined areas.

-

Table Level Displays Information on Separate Device

Big Kaiser’s Level Master Wireless is a high-precision device for leveling machine tool tables.

-

Zero-Point Clamping System Facilitates Multi-Axis Machining

Big Kaiser’s Uniflex three-dimensional, zero-point clamping system is designed to allow parts with curved surfaces to be held rigidly for various operations and to be adjusted to different height requirements.

-

Rugged Boring Heads Connect to Internet of Things

Smart Manufacturing Experience 2018: Big Kaiser’s EWE boring heads are intended to provide measurable performance advantages, significantly reducing finishing cost and cycle time.

-

Machine Tool Sensors Determine Workpiece, Tool Offsets

Big Kaiser has introduced the Base Master Red and Base Master Mini machine tool sensors.

-

Chamfering Tool Reduces Cutting Resistance, Burr Generation

Big Kaiser is introducing the R-Cutter CKB Type, a modular round chamfering tool.

-

Automated Boring Head Delivers Lights-Out Control of Fine Hole Making

An app to assist machinists in finish boring was the beginning. Now, servo control allows the app’s adjustments to be made automatically, allowing the process to run unattended.

-

Taking the Drag out of Automotive Machining Setups

Paired with the right cutting tools, workholding and software, multi-tasking and multi-axis equipment enables this race team to also bill itself as a full-fledged parts supplier.

-

What We Learned at Westec 2017

Westec offered a useful mix of emerging technology and practical applications. This slide show reflects this mix in its eclectic coverage of what exhibitors had to offer.

-

Small Chucks Ideal for Micromachining in Confined Areas

Big Kaiser offers its smallest hydraulic chuck for HSK-E25 machine spindles, completing its line of Super Slim hydraulic chucks.

-

Workholding System Suits Five-Axis Machining by Clamping Underneath

The clearance is an added benefit of the quick-change system, potentially facilitating five-axis as an automation tool.

-

ER Clamp Available in More Big Plus Taper

Big Kaiser’s Mega ER grip is designed for high clamping force, concentricity, rigidity and balance at high spindle speeds.

-

Lathe Boring Bar with Integrated Damper

Big Kaiser offers its Smart Damper boring bar for lathe applications.

-

Slim Milling Chuck Provides High Gripping Force

Big Kaiser has launched the HMCJ, a super-slim milling chuck with peripheral coolant supply, designed to support heavy-duty and finish-end-milling tasks with power and precision using ½"- or 12-mm-diameter cutters.

-

When a Turn-Mill Doesn’t Turn

LeanWerks uses innovative probing, tooling and workholding strategies to enable its turn-mill to machine castings complete, in effect turning it into a five-axis machining center.

-

NTMA Members Share after Japan Manufacturing Tour

U.S. shop owners and managers comment on the plants they visited, automation and culture, and the value of getting to see manufacturers far away in the company of other shop leaders.

-

Milling Chuck Eliminates Pullout while Machining HSRAs

Big Kaiser introduces the Mega Perfect Grip from Big Daishowa, a milling chuck for machining heat-resistant super alloys (HRSAs) like titanium or Inconel, designed to eliminate end mill pullout under heavy torque loads.

-

Air Spindle Enables Micromachining on Existing Machines

Big Kaiser’s RBX12 air-drive spindle achieves variable rotational speed of 100,000 to 120,000 rpm and enables existing machines to be upgraded for high-speed micromachining.

-

What To Consider When Adding Angle Heads

Angle heads can enable a three-axis machine tool to be more versatile. That said, this shop explains that there’s more to getting started using them than simply loading them into a machine’s spindle.

-

Testing Measures Impact of Toolholder Interface Rigidity

Though Big-Plus and HSK share superficial similarities, they differ fundamentally in how they clamp the holder--a difference with important implications.

-

Swiss Technology Tour

A recent Switzerland tour organized by the NTMA revealed insights on machine and spindle collision protection, fluids for deep-hole drilling and more.

-

Digital Tooling Improves Accuracy, Reduces Scrap

By switching to digital boring heads, Impact CNC was able to reduce its scrap rate while increasing precision.

-

Video: Multi-Axis Quick-Change Workholding

Whether you’re working on complex or relatively straightforward geometries, matching the workholding and tooling to the application maximizes performance.

-

Clamping System Replaces T-Slot Platter

Big Kaiser’s modular Unilock zero-point clamping system is now available in a kit designed for Haas 160-mm platter rotary indexing tables.

-

Entry-Level Tool Presetter Resists Temperature Fluctuation

The Diaset 240 contact presetter from Big Kaiser Precision Tooling features mineral cast construction, an updated spindle and a new digital control readout.

-

What’s Best for Boring Titanium?

In a joint research effort, Kaiser Precision Tooling and Blaser Swisslube searched for a combination of metalworking fluid and indexable insert that show the best results when boring titanium. The results underscore the importance of controlling vibration, friction and heat.

-

Behind Closed Doors

Lang Technovation’s Clean-Tec fan clears away chips and coolant inside enclosed machining centers.

-

Doubling Down on Setup Reduction

Angle heads still find plenty of use for reducing setups, even in shops using sophisticated multi-axis machine tools.

-

The Benefits and Limitations of Machining With an Angle Head

Far from being outdated by the latest machine tool technology, angle heads often prove an ideal complement by pushing done-in-one capabilities even further. Proper application, however, requires attention to their limitations as well as their benefits.

-

Precision-Finish Boring Head for High-Speed Spindles

Big Kaiser’s EWN 04-7 series of precision-finish boring heads are designed for use on micro-milling machines with high-speed spindles such as HSK-E25, E32 or E40.

-

World’s Smallest Boring Head?

With a diameter range of 0.016” to 0.276”, this boring head is well-suited for a variety of micromachining applications.

-

Precision-Finish Boring Head for Micro-Milling

The Big Kaiser EWN 04-7 series precision-finish boring head is designed for micro-milling machining with high speed spindles such as HSK-E25, E32 or E40.

-

Worth Three Machines

A shop that closely tracks machining performance says its new horizontal machining center delivers productivity comparable to three verticals.

-

The Big Step Up

A small shop added two new machines, each of which is more advanced than any of the previous machine tools the company has used. One of the co-owners committed to the work of bringing both of these machines fully into service. Here is the shop’s experience so far.

-

Innocent Until Proven Guilty

When something goes wrong with a machining process, it can be easy to misplace blame.

-

Andretti Autosport Finds Shared DNA, Culture with BIG Kaiser

The Mega E collet chuck and a Speroni presetter are among the products the race team cites as critical to success in the shop and on the track.

-

When Reshoring Really Happens

Bob’s Design Engineering illustrates how a shop that used to be organized for short-run work transformed its process for ongoing production.

-

Rigidity Proves Key to Precision Boring

Thanks to a more rigid boring head from Big Kaiser Precision Tooling, a new machine that had been relegated to only roughing jobs is now holding the tight true-position and diameter tolerances that this shop’s customers have come to expect.

-

BIG Kaiser Tooling System Can Handle Large Workpieces

Designed for machines such as Makino’s T2 and T4 models, BIG Kaiser’s HSK-A125 tooling system is capable of tackling large-scale titanium and other workpieces on large tables, making it especially suited for use in the aerospace industry.

-

ER Collet Chuck System Offers Rigidity, Balance

With a runout accuracy of 0.00012" (3 microns) at 5×D, BIG Kaiser’s Mega ER Grip is designed to increase clamping force, concentricity, rigidity and balance at high spindle speeds.

-

Hydraulic Chuck Promotes Smooth, Stable Cutting

BIG Kaiser’s high-precision hydraulic chuck is designed for clamping straight-shank tools with diameters ranging from ¼" to 1¼" and 6 to 32 mm.

-

Last Glance at IMTS 2010

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

-

Presetting Process Cuts Scrap, Rework

Aerospace manufacturer Fokker Aerospace Group relies on Speroni’s STP46 tool measuring and presetting machine to ensure that step drills used to cut and chamfer holes on aircraft flap skins are within tolerance and set to the proper length. This machine and custom procedures developed by Speroni enables the aerospace manufacturer to avoid cost and downtime resulting from reworking or scrapping these large parts.

-

Expanded Modular Tooling System

BIG Kaiser Precision Tooling has expanded the Kaiser KAB modular tooling system capabilities to include the rigid, high-feed C-Cutter Mini chamfer mill line from BIG Daishowa Seiki.

-

BIG Kaiser Grand Opening

BIG Kaiser Grand Opening

-

HSK Turning Tools For Mill-Turns

BIG Kaiser Precision Tooling has expanded its turning tool line to include HSK-T63 tools for mill-turn centers (MTCs).

-

Synchronous Tapping Holder And More

The company says its synchronous tapping holder, the Mega Synchro, compensates for synchronization error during rigid tapping by reducing the thrust load to both the tap and workpiece.

-

CKN Modular System For Large Boring

BIG Kaiser Precision Tooling’s CKN modular connection utilizes both steel and lightweight aluminum components.

-

Reducing Thrust Loads During Rigid Tapping

Some amount of synchronization error is inevitable with rigid tapping. By allowing just a slight amount of axial movement to compensate for synchronous errors, this tapping holder is said to reduce thrust load by as much as 90 percent.

-

How Do You Machine a 30:1 Hole in Stainless Without the Drill Wandering?

An expert in micromachining says one answer is to check various aspects of the drilling process. Another answer is not to use a drill at all.

-

Tapping Holder Improves Thread Quality And Tap Life

The Mega Synchro tapping holder compensates for synchronization error during rigid tapping by reducing the thrust load to both the tap and workpiece, improving thread quality and tap life. This is facilitated through a mechanism that absorbs the pitch difference between the tap and synchronous spindle. Capable of supplying coolant through slits to the tap periphery, the holder is available in various lengths and spindle interfaces to suit any company’s needs.

-

Too Small To Touch

Hummingbird takes on machining work that is too small for most shops to handle. In fact, Hummingbird tries not to handle it either. To accurately machine the tiniest parts, this shop relies on processes that are as hands-off as possible.

-

Applying A High Speed Machining Discipline Without The Speed

In this shop, high speed machining makes sense at 4,000 rpm. While the disciplines the shop put in place made a new 15,000-rpm profiler dramatically more productive, high speed machining would have remained valuable even if the new machine never came. Acoording to a co-owner of this shop, high speed machining has no need for speed.

-

Milling Chuck Pumps Up Productivity

Rigid toolholding offers a platform for productivity on this pump manufacturer's mill-turn center.

-

A Practical Guide To Presetters

Tool measurement devices help shops save time, control runout and improve tool management.

-

Vacuum Workholding Method Fits New Machining Strategy

Increased demand for armor plating components led this shop to completely revamp its machining technique. Rather than machining individual workpieces, the shop produces multiple components nested in an aluminum plate. A custom vacuum workholding system plays a significant role in this new strategy.

-

Boosting Machine Spindle Speed For Micromachining Applications

Small-diameter micromachining tools require very high rpm for sufficient cutting speed and material removal rates. This air spindle provides 80,000 rpm and an untethered compressed air interface to allow automatic changeovers using the machine's ATC.

-

The Real Cost Of Runout

A seemingly small amount of runout can still be too large for the tool. Reduce this runout, and tool life or productivity may dramatically increase.

-

An Indexable Insert

The solid end mill is a machine shop staple. Its positive cutting edge removes metal by slicing through the material, rather than by scraping.

-

Tooling Reduces 21 Minute Job To 9 Minutes

Shop leadership was looking for a way to reduce the time it took to complete a very difficult boring job. The job took 21 minutes per part to complete with multiple roughing and finishing processes. It required 10 minutes of hone time.

-

The Role Of Balance In High Speed Finish Boring

Precision boring is particularly vulnerable to unbalance, but not every high speed boring application demands a balanceable tool.

-

Setting Tools Makes Small Shop Sense

Some people think tool presetting can be justified only in large operations. This Arizona shop shows how it makes sense almost anywhere.