Vacuum Workholding Method Fits New Machining Strategy

Increased demand for armor plating components led this shop to completely revamp its machining technique. Rather than machining individual workpieces, the shop produces multiple components nested in an aluminum plate. A custom vacuum workholding system plays a significant role in this new strategy.

Share

Changes in customer delivery demands can sometimes lead shops to make fundamental changes to their machining practices. Jet Machine did just that a little more than a year ago.

The majority of this shop’s work is dedicated to producing aluminum plating components used for military vehicle up-armor retrofitting programs. The armor plating kits are field-installed on Humvees to provide perimeter, roof and underbody blast protection for those vehicles. Early on, these programs required Jet Machine to provide armor plating for 35 vehicles each month. Recent military developments, however, have caused orders for armor plating to rise dramatically. The shop now supplies components to outfit approximately 600 vehicles per month. It couldn’t have achieved this dramatic throughput increase without completely re-thinking the way it originally machined armor plating components.

In the past, individual workpieces were set up and machined from sawn blanks one piece at a time. So the bulk of each workpiece’s total cycle time was consumed by non-value-adding setup procedures. Now, Jet Machine has a “nested plate” mindset. By using custom vacuum workholding systems on large-table VMCs, the shop is able to machine complete kits of armor components from a single, 1-inch-thick plate of 6061-T6 aluminum. In addition to greatly reducing setup time, this approach frees machine operators to perform deburring and other duties while the machine tools are making chips.

During a recent visit, Rick Wulfeck, Jet Machine’s president, described how his new machining strategy, paired with 24/7 production scheduling, allows his shop to keep pace with customer demand.

Workholding With Negative Pressure

Effectively machining multiple components from an aluminum plate measuring 31 by 144 inches is easier said than done. One part of Jet Machine’s challenge was to identify a machine with the table capacity to fixture such workpieces. The shop found that the Cincinnati Machine FTV 840-3700 fixed-table verticals offered the requisite table size as well as a 10,000-rpm spindle to allow fast, light cuts in aluminum. In addition, the machines facilitate material loading and workpiece removal by allowing operators to belly-up very close to the worktable. The shop purchased two of the FTV machines through GBI Cincinnati.

The next challenge was to identify an effective workholding method to secure the workpieces for machining. Fixturing such sizeable plates so that their bottom surface remains completely flat against the machine table would have been difficult, if not impossible, using conventional clamps. And magnetic workholding wasn’t an option because the plate material is nonferrous. So GBI Cincinnati worked with Vac-U-Lok to develop a multi-station vacuum workholding system to secure the plates for milling and through-hole drilling operations, as well as periphery machining to remove the individual components from the nest.

To appreciate the complexities of Jet Machine’s vacuum workholding system, it is helpful to have a general understanding of how a vacuum chuck operates in a straightforward application. A typical vacuum workholding system consists of a vacuum pump, a vacuum chuck, a coolant return and a safety device. The industrial vacuum pump, which pulls approximately 13 psi of vacuum, is plumbed to a vacuum chuck that has various port holes on its top. The vacuum developed by the pump pulls the bottom workpiece surface down against the chuck. Gasket material that resembles weather stripping seals the vacuum between the chuck and workpiece. The gasket material installs in a grid of channels milled into the top surface of the chuck. When vacuum is applied, the workpiece compresses the protruding portion of the gasket material to maintain vacuum seal and fixturing force for machining operations.

The total fixturing force that a vacuum system can provide is a function of the bottom surface area of the workpiece multiplied by the psi of vacuum the pump pulls. In the case of the 31 by 144 aluminum plates, for example, this would work out to approximately 58,000 pounds of holding force at 13 psi of vacuum.

A coolant return device is also required because the vacuum system will naturally try to pull in coolant used during machining operations. To recover the coolant and keep it from reaching and damaging the vacuum pump, Vac-U-Lok systems use a two-chamber coolant return device that automatically collects and drains captured coolant without requiring the vacuum chuck to be shut down for coolant return. The last major system component, a vacuum safety device, is wired to the machine’s E-stop. This device detects the system vacuum level and shuts down the machine in the event the vacuum level reaches a user-defined minimum limit.

Piece Parts From Nested Plates

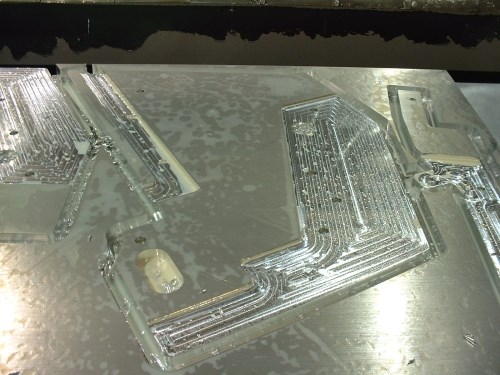

One reason Jet Machine’s vacuum workholding application isn’t run-of-the-mill is because many of the individual components nested in the plate require through holes to accept fasteners during assembly. Drilling through holes in a workpiece installed directly on a vacuum chuck would damage the chuck. In addition, drilling a hole would cause the workholding system to lose its vacuum seal (thus fixturing force). Because multiple parts are cut from a single workpiece plate, the vacuum seal would also be broken once a component is machined free of the nest. These challenges require the use of a custom adapter plate that installs atop the vacuum chuck as well as an accompanying milling strategy for cutting components from the nest.

The adapter plate is sandwiched between the vacuum chuck below and workpiece plate above. Vacuum from the chuck pulls down on the workpiece through various port holes in the adapter plate. Like the vacuum chuck, the adapter plate has channels on its top surface to accept the sealing gasket material. But instead of a general grid, the channels in the adapter plate follow the outline of the components nested in the workpiece. When the final cutting pass breaks through the material, the gasket material located just inside the perimeter maintains the vacuum’s hold on that specific component.

When a component requires a through hole, a blind hole is located in the adapter plate at that position. This allows the drill to pass completely through the workpiece without damaging the adapter plate (see photo at far left of the group of three, above). Gasket material installs in channels around these blind holes to maintain the vacuum seal.

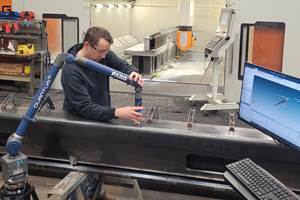

An operator begins each new machining job by using (not surprisingly) a vacuum workhandling device to load a workpiece on the adapter plate. Once the workpiece is maneuvered into place, vacuum is applied to secure it for machining. If the workpiece isn’t extremely flat, operators will tap on its top to establish the seal between it and the adapter plate below. Once fixturing is completed, the 40-minute machining cycle begins.

The armor plating components receive various through-hole drilling and top surface milling operations before being machined out of the nest. To remove a component from the nest, a 0.75-inch end mill is driven around the component’s perimeter, taking numerous passes that are 0.3 inch in depth. These passes continue until the material attaching each component to the nest is only 0.1 inch thick. This milling technique keeps the bottom surface of the workpiece intact, allowing the vacuum to pull against that large surface area (thus maintaining high workholding force).

When the final 0.1 inch of thickness around the perimeter of each component is milled away, the cutting tool pressure generated is such a small amount that the vacuum pulling force under the components prevents movement. Minimizing tool pressure in this way allows the components that normally would be too small for vacuum workholding independently to remain fixtured for machining operations.

According to Vac-U-Lok, it is possible to mill individual components from very flat workpieces to 0.003 inch of remaining thickness so that even less cutting tool pressure is generated. Jet Machine chooses to mill to 0.1 inch because some of the plate material it receives isn’t perfectly flat. The company doesn’t want to risk breaking through a warped portion of the workpiece while the machine is taking a 0.3-inch depth of cut because that could scrap a component.

After machining, the part program calls for a plastic chip fan, available from Big Kaiser, to be installed in the machine’s spindle. The spindle rotates the fan as it traverses the top of the plate, blowing away chips and coolant. The machine operator then uses suction cups to help pop components out of the nest remnant. Other employees inspect and deburr the parts while the operator prepares the machine for a new job. The machining cycles for the two machine tools are staggered so the machines are not down at the same time. That allows a single operator to tend both machines.

Operators must take care when removing components and nest remnants (which are recycled) from the machine so that the gasket material on the adapter plate isn’t torn or damaged. The gasket material does wear over time and must be periodically changed. Jet Machine’s 24/7 production schedule has it changing gasket material every two weeks.

The operator next takes a shop vac and removes any chips that remain on the adapter plate before installing a new workpiece. That’s because any chips left behind could damage the adapter plate and/or gasket material when a new workpiece is installed.

Added Motivation

For many shops, simply maintaining a good customer’s business is motivation enough to make changes that will improve production efficiency. The employees at Jet Machine are also driven by the fact that the components they help produce are being used to protect those who are protecting us all. The shop has even received letters of thanks from families of soldiers whose lives were saved on the battlefield because of the armor plating it machines.

That has to be a great feeling for all shop employees.

Related Content

ESOP Solidifies Culture of Continuous Improvement

Astro Machine Works’ ESOP rewards all employees when the shop does well, inspiring many toward continuous improvement as Astro expands its capabilities.

Read MoreSelect Machining Technologies Highlights Multitasking Machines

IMTS 2024: Select Manufacturing Technologies is highlighting large-capacity multitasking machines from Solace, Geminis, Ibarmia and Momentum.

Read MoreHow a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)