Putting Production on Repeat with Machine Tool Automation

Cobots and automation advances have spurred tooling and workholding innovations like Big Daishowa’s zero-point workholding system and EWA fine boring head.

Share

Alan Miller, engineering manager and product manager for Big Daishowa, said in a September 28, 2021 webinar that improvements to collaborative robot systems have opened up automation to a wider array of manufacturers than ever before. Between these cobots and automation-optimized tooling, manufacturers can now automate smaller, specific, repetitive operations with less investment in time and resources. This frees up operators to tackle high-complexity operations that require manual input, while speeding up productivity and improving safety in simpler tasks.

Cobots

Collaborative robots, or “cobots,” widen the range of processes compatible with automation. Cobots are designed to work alongside employees, with integrated safety features like force limits automatically stopping the cobots when they meet unexpected resistance. Improved speed control, vision systems and proximity sensors, coding simplicity and increased adaptability also enhance the functionality of these automation solutions.

As part of encouraging the use of cobots, tool manufacturers like Big Daishowa have developed optimized solutions to take advantage of their increased functionality.

Automation, One Step at a Time

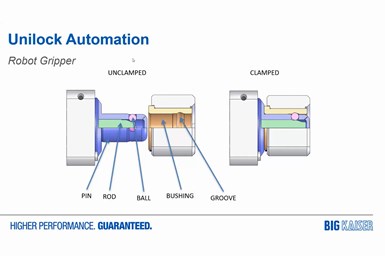

The gripper of Big Daishowa’s Unilock workholding systemis optimized for use with cobots. It was designed to eliminate the tight diameter and spacing control problems of retention knobs, which had prevented automation with earlier generations of zero-point workholding. Images courtesy of Big Daishowa.

Miller points out four applications where Big Daishowa has developed tooling to support the automation revolution: workholding, grinding work driving, cleaning and fine boring.

Workholding

The company’s Unilock workholding solution includes several optimizations specifically for use with automation. Miller says the chuck mounts directly to the machine tool (as well as other places, if needed), with a single reference point for fixtures or loading parts.

Miller also says that traditional zero-point workholding systems with tight diameters and spacing controls on the retention knobs can be difficult for robots to unload. Using a robot on these systems can lead to the workholding devices locking up or not fully coming out.

To combat this, Big Daishowa flipped the system inside out for automation. The chucks from its NSA Series have the clamping systems and tapers on the table — Miller compares this to what would be underneath the pallet of a horizontal milling machine. Flat, round pucks go underneath the work pallet, where Miller says they can easily slide on and off to improve the system’s compatibility with robots. The system uses a central chuck, but users can attach four additional locator plates to have built-in angular positioning while loading the chuck.

Work Driver

Traditionally, grinding work drivers need to be manually attached to each work piece, so automation would take the form of preassembled parts with attached work drivers. Miller says Big Kaiser’s line of mechanically actuated grinding work drivers instead uses spindle rotation to lock and unlock the drive, with adjustable jaws swinging into place and grabbing onto the workpiece.

Cobots are more compatible with this mechanically activated system, and can facilitate automated loading and unloading of small shafts. If the cobot runs into any problems, rather than proceeding to cause damage like a traditional robot, it stops and waits for an operator to assess the issue.

Cleaning

Keeping the work area clean is critical to successful automation project, Miller says. Big Daishowa recommends two ways to automate this task: the chip fan and the chip blower. The chip fan is a fixed and balanced blade fan with a small, 125-mm diameter that requires high spindle speeds to be effective, while the chip blower is a folding blade fan that covers more area at lower speeds — making it suitable for larger machines and tables.

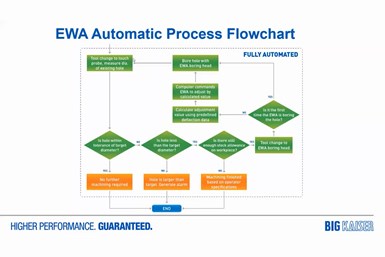

The EWA fine boring head offers automated adjustments and cutting insert wear compensation. The level of automation can be set to the user’s comfort, from adjustments to user-input values to fully automated boring from the machine tool control.

Fine Boring Heads

New opportunities for automation are not limited to cobot-optimized workholding. Miller says Big Daishowa wants to enable full automation of the fine boring process.

Removing the need for manual adjustment could reduce cycle times and the risk of human error while also improving operator safety. The company’s EWA line of finish boring heads, scheduled for release in early 2022, moves toward this goal with an internal motor for automatic tool carrier adjustments, an internal actuator for clamping the tool carrier, and Bluetooth to communicate with external devices.

Automatic cutting insert wear compensation features adjust the boring tool for potential wear compensation based on measurements from the machine touch probe and bore gauge. Automatic adjustments can also enable a single tool to bore multiple hole sizes.

Bluetooth connectivity enables differing levels of automation, depending on the user’s comfort. Similarly to the EWE, the EWA can connect to users’ smartphones and tablets. In this situation, the machine operator inputs adjustment values in the app, then the tool adjusts automatically to the set value. This keeps the operator’s knowledge of fine boring in play, while still benefiting from the automated adjustment’s safety and tooling benefits.

Connection to an external computer that is itself connected to the machine enables the boring head’s probe to transfer measurements to the computer. From here, the computer can command the EWA boring head for adjustments. This system automates the boring head, while still keeping it separate from the machine tool control.

Direct connection with the machine uses Bluetooth to enable the machine to control the EWA boring head’s adjustments. Miller says Big Daishowa is actively working with companies to develop in-machine apps that improve compatibility with this automation method.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)