Workholding 101

No universal workholding solution exists, so machine shop employees should have a basic understanding of multiple ways they can secure workpieces.

Share

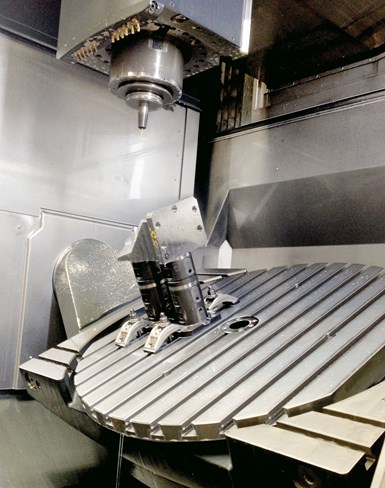

Workholding takes many forms, but jaw chucks are one of the most common solutions for turning and three-axis milling applications. Photo sourced from iStock.

Tooling and machines may be the flashy highlights of manufacturing, but workholding is just as important to successful production. Workholding makes use of a fixture — often categorized by the machine for which it is designed — to position and keep a part steady during machining.

What Are Common Fixtures?

Chucks are clamps that traditionally hold radially symmetrical objects, but some can hold irregular objects. Different chucks can hold tools or workpieces stationary, and some rotate. Jaw chucks clamp with a radially arranged set of jaws, while collet chucks form a “collar” that exerts clamping force when tightened. Different types of chucks can hold parts’ inside diameter or outside diameter.

Vises also secure workpieces through clamping — traditionally between a fixed jaw and a movable one threaded in and out by a screw and lever.

Pallets are a common means of holding multiple workpieces and reducing part-handling times. Some machines include pallet changers that can swap pallets with finished workpieces for fresh pallets with new workpieces. Pallets are often paired with tombstones: multi-sided fixtures that rotate to present a batch of fresh workpieces to the spindle after parts on one side are machined.

A tailstock is the non-motorized “tail” end of a turning machine that holds one end of the workpiece. A small hole made in the workpiece just before turning provides the leverage for the tailstock’s conical center.

Some fixtures are “indexing” fixtures, meaning they can locate to within a few hundredths of a millimeter (or thousandths of an inch). While the term can officially refer to positioning on the X-, Y- and Z-axes, for workholding it tends to refer to rotational positioning.

Collet chucks have a narrower range of viable applications than jaw chucks, but they offer speed and weight benefits where compatible. Photo sourced from Getty Images.

Jaw Chucks vs. Collet Chucks

Collet chucks are not as versatile as jaw chucks, but they offer speed, accuracy and productivity advantages in certain applications.

For example, collet chucks’ lighter weight can make them a wise choice if the combination of jaw chuck and workpiece is too heavy for bearing load requirements. Lower mass also translates to higher spindle speeds and acceleration, as well as less susceptibility to centrifugal force. Collet chucks hold tighter tolerances than jaw chucks with bored soft jaws (0.0005-inch total indicator runout (TIR) compared to between 0.0006- to 0.0012-inch TIR), and as such are better for maintaining the accuracy of secondary operations or for ensuring concentricity during installation. Quick-change collet chucks are changeable within 15 to 20 seconds, compared to quick-change jaw chucks’ minute or regular jaw chucks’ 15 to 20 minutes — making them a better option for very large and very small lot sizes.

Collet chucks are compatible with a smaller range of workpiece sizes, however. They are best suited for diameters smaller than 3 inches, and are much better with consistent part sizes. Workpieces long enough to require nearly all the machine’s travel can also pose issues for collet chucks. For large or variably sized parts, jaw chucks are generally the better option.

Collet chucks tend to be more useful for cold-rolled material, while jaw chucks are generally better for hot-rolled steel, castings, forgings and extrusions.

Tombstones can hold multiple workpieces on each of its sides, rotating as needed to ensure a horizontal machining center is constantly in use. Photo courtesy of Alicat Scientific.

Workholding for Horizontal Machining Centers

Fixtures for horizontal machining centers (HMCs) are often more sophisticated than their counterparts on vertical machining centers (VMCs). Vises prove less useful due to orientation issues, and edge, toe and wedge clamps are more common. These machines also tend to use automated pallet changers and tombstones.

Automated pallet changers (APCs) move pallets in and out of workzones. They tend to be rotating carriers with two sides separated by a panel. One pallet faces the machining zone and is lifted onto the table for machining, while users handle the pallet on the other side of the panel. By continuously exchanging pallets, the APC reduces the HMC’s downtime.

Tombstones are upright fixture blocks that, as mentioned earlier, have multiple sides onto which parts may be mounted for machining. They are typically made from aluminum or case iron and have bolt holes for attaching fixtures and clamps to hold parts. They can also be mounted on movable pallets to be shuttled in and out of machines.

HMC workholding can make use of hydraulics and pneumatics to provide clamping force. Some machines have the option to plumb hydraulic or pneumatic lines through the pallet and leverage multiple fixtures without replacing lines or fittings.

Five-axis workholding strategies differ heavily from three-axis strategies, with old standbys like jaw clamps being unsuited for the flexibility of five-axis operations. Photo courtesy of Big Daishowa.

Five-Axis Workholding

Five-axis workholding requires a specialized approach. What worked on less flexible, three-axis machines can limit the freedom of movement and workpiece access that make five-axis machining attractive. Instead, users will need to carefully consider the interference and clearance relationships between the workpiece fixturing, machine table, spindle housing and cutting tools.

Interference and clearance issues are especially bad when machining small parts on large tables. If machining the part in the center of the table, the edges of the table could collide with the spindle during pivots. Three-axis users inclined to purchase the largest machine possible might find that a five-axis machine sized to their parts works better.

Long tools can overcome interference, but increasing length-to-diameter ratio makes a tool more prone to chatter and limits feed rates, speeds and depths of cut. Elevating the workpiece is another common method for overcoming interference, using devices like tall jaws. Similarly to long tools, however, clamping spindles suffer reduced effectiveness far from the jaw. In extreme cases, clamping forces can even tilt tall jaws into a V shape that loses the part.

Dovetails can prove useful for five-axis parts 6 inches by 6 inches or smaller, giving access to five sides of a workpiece for machining. This type of fixturing does not work well on curved surfaces, however, and cannot be used on parts with varying widths. Self-centering vises are also common because of their similarity to three-axis workholding, but grabbing the workpiece from two opposing sides can reduce part access.

Specialized Workholding Methods

The pocket and the two clamps on this 3D-printed workholding fixture for a molded plastic part were designed around the part geometry. Print time was about 20 hours at a cost of $26. Precision Metal Products estimates that creating this piece conventionally in the toolroom would have taken a week at a total cost of $2,500. Photo courtesy of Precision Metal Products.

3D Printed Fixturing

Organic shapes and untraditional features can present challenges with workholding for additively manufactured parts. Thankfully, the problem also holds the solution: 3D printing can create custom fixtures with unique shapes that can secure additively manufactured workpieces.

Diaphragm Chucks

Diaphragm chucks rely on elastic deformation rather than traditional wedge-and-master-jaw clamping techniques. Advantages include a consistent grip force and no need for lubrication.

These chucks are particularly useful for hard turning gears. They help maintain centering accuracy, and thus can eliminate the need for bore grinding after the gears are machined and heat treated. This accuracy also makes them well-suited to secondary operations, especially on surfaces that could be damaged by serrated jaw grippers.

Magnetic Workholding

Electro-permanent magnets make magnetic workholding a possibility by combining the advantages and mitigating the weaknesses of electro-magnets and permanent magnets. Whereas electro-magnets would cease holding workpieces if the power supply failed (an extremely dangerous proposition) and permanent magnets would exert too much force on parts with lots of surface area, electro-permanent magnets can have their polarity switched by a burst of electrical current. Workholding setups using electro-permanent magnets include two sets of magnets: a permanent set that is always oriented in one direction and a switchable set, which is surrounded by an electric coil that enables polarization. When the polarities of both magnet sets align, the setup works at maximum strength. When the polarities differ, they cancel each other out.

Top tooling in these systems can accommodate many workpieces, and because these magnets retain their polarities until a new burst of electrical current deactivates the magnets, they are portable on palletized machine tools.

Magnetic workholding is swift, with no need to position clamps, and poses no interference on the sides. Workpieces must be ferrous for compatibility, however, or the user must use an additional ferrous fixture on top of the magnet. Photo courtesy of D1 Mold & Tool.

In these systems, workpieces should be positioned as bridges connecting the poles of magnets to maximize their exposure to magnetic flux. Low-carbon top tooling can be arranged to support smaller workpieces on the bottom and side if they don’t have sufficient surface area to bridge the poles. Users can also deliberately sacrifice some holding power by keeping the bottom of a workpiece non-magnetic. This helps prevent chips from accumulating and forcing a recut. Smooth-surfaced workpieces are more tightly held than rough-surfaced parts in magnetic workholding, and annealed materials conduct magnetic flux better than hardened materials.

Magnetic workholding provides consistent clamping pressure and full support of the workpiece surface. Decreased chatter enables higher speed and feeds, and the lack of jaws leads to no interference on the sides and the elimination of time spent adjusting clamps. Less equipment to manage also simplifies programming.

These systems can be set up with pole extensions that raise the workpiece above the surface of the magnetic table to enable through-hole drilling, as well as gripping of contoured or warped workpieces. If the magnets are installed on a machine table, as in a sub plate, workpieces can be attached directly to the magnet surface — or the user can add a ferrous vise or fixture to take advantage of magnetic workholding’s fast setup capabilities even when machining non-ferrous workpieces.

Vacuum Workholding

Vacuum workholding has a niche in machining thin parts, particularly those that would bow in a vise. Compressed air creates suction, and increasing the amount of surface area under the vacuum increases the holding force. Side-load is a concern without nesting because the holding force is only downward. Users will also need to modify feed rates, cut depths and cut widths. Machining through-holes also can be difficult because punching through the material punctures the vacuum.

Fresmak’s chemical workholding fixtures activate in response to high temperatures, and exert about 1000 N/cm3 of adhesive force when cooled. They are compatible with many material types, and offer more stability than vacuum workholding. Photo courtesy of Fresmak.

Chemical Workholding

Chemical adhesion-based workholding systems are compatible with many materials, and can support greater cutting force than vacuum workholding. What’s more, chemical workholding fixtures grip only one side of a workpiece, leaving the other five open for machining. These systems are activated through heating and cooling cycles, which take long enough to warrant identical setups for continuous production (one setup can heat or cool while another is in the machine tool).

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreFive Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More