Share

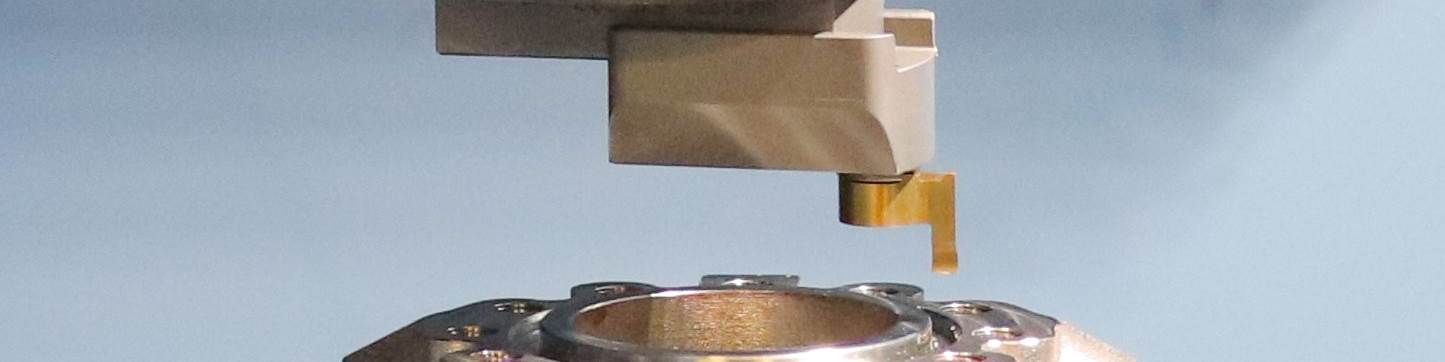

The mechanical nature of the face grooving attachment holds size much better than end mills, Big Daishowa says, vastly reducing the need for cutter compensation. Utilizing down feeding instead of a circular tool path also eliminates interpolation errors. Images courtesy of Big Daishowa.

Metal 3D printing via laser powder bed fusion is an expensive process, one which leaves little room for failure in postprocessing steps. Keselowski Advanced Manufacturing (KAM) knows this perhaps a little too well — one sealing groove on a turbo pump assembly proved complicated enough to consist of 30% of the part’s CAM programming tree and required multiple operations with high tool wear, but the high costs of failure discouraged experimentation. Process revisions and new tools needed to offer significant time and tool life savings to justify the risk of failure during process validation. Ultimately, a face grooving attachment from Big Daishowa met KAM’s needs, enabling the manufacturer to reduce cycle times for the operation, extend tool life and improve repeatability.

Material Matters

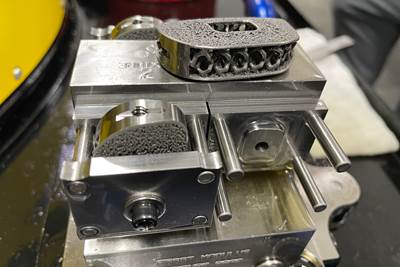

KAM works with difficult alloys such as Inconel 625 and 718, Ti64 and Haynes 282. Machining these from billet would cause problems with both machining cycle times and tool life, so the parts are made additively instead. Metal 3D printing produces a near-net shape with geometries optimized for the necessary postprocessing, utilizing features which enable simple fixturing during machining and build design that supports specific machining approach angles.

The high-nickel alloy KAM uses for its turbo pump assemblies has high ductility and malleability, but is abrasive enough that James O’Toole, KAM’s vice president of engineering and sales, says working with it is “almost like cutting sandpaper.” Limiting machining to additive manufacturing postprocessing steps is a massive time and cost saver for KAM, but even these operations can act as bottlenecks when unoptimized.

Laser powder bed fusion drastically increases the ease of working with hard alloys such as Inconel 625, but the costs of both material and process mean mistakes during postprocessing steps are disastrous.

Stuck in a Rut

Before KAM began to make changes, creating a sealing groove in the turbo pump assembly required two 0.093” carbide end mills, one for roughing and one for finishing. The abrasiveness of the material limited cutting speeds to about 100 sfm and held feed rates at less than 10 ipm. Tolerances needed to be tight enough to work as a seal, and the shop often performed secondary turning operations to achieve a circumferential lay with a surface finish between 4 and 16 μm Ra.

Significant wear problems also plagued the operations. “Because of the amount of time it was taking to cut that groove and the amount of wear that was on the tool, we were essentially having to change the end mills every part,” O’Toole explains. “There was constant remeasuring of the slot width and comping out tools. It was taking almost an hour to rough and finish with all the stopping and starting.”

A New Groove

KAM used Big Daishowa’s EWD Digital Boring Heads even before optimizing the grooving operation. The preexisting relationship led the manufacturer to consider the OEM’s EWN/EWE 2-152 face grooving attachment, with a test cut rapidly proving out the revised operation using the attachment.

“The face grooving attachment swings in a 2.087”-diameter arc, much larger than the end mill,” O’Toole says. This extended effective diameter enables KAM to achieve the same surface speed with a slower spindle speed. The greater level of control from this slower spindle speed leads to fewer, finer adjustments. These adjustments also benefit from the digital readout on the EWD Digital Boring Heads, which provide feedback based on the movement of the head rather than dial rotation, a change which helps overcome backlash concerns.

“The goal is to maximize throughput, not just when we’re on site, but also when we’re not,” O’Toole says.

The altered face-grooving process also reduces how much time the tool spends in the cut. “Because the feed rate is established on the down feed, meaning we’re feeding it into the part at a specific feed rate, rather than moving in a circular motion along that two-inch tool path . . . we’re talking about taking more than 45 minutes out of an operation,” O’Toole says. The process also creates a more consistent surface finish, eliminating the secondary turning operation.

By decreasing the amount of time the tool spends in the cut and improving process efficiency, tool life for the operation has increased from two inserts per part to 30 parts per grooving attachment, and each attachment lasts between five and 10 parts before requiring an adjustment. This vast increase in productivity and repeatability has led KAM to begin performing the grooving operation as part of its lights out schedule.

“The goal is to maximize throughput, not just when we’re on site, but also when we’re not,” O’Toole says. With thirty times the tool life and a 75% shorter cycle time, this process revision more than met KAM’s goal.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

How to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreWhy Was CNC Machining on Display at the Biggest Show for Additive Manufacturing?

Machining is a complement to AM as a means of finishing metal 3D printed parts. The increasing adoption of AM for production means more need for postprocessing, particularly machining.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read More