Reducing Thrust Loads During Rigid Tapping

Some amount of synchronization error is inevitable with rigid tapping. By allowing just a slight amount of axial movement to compensate for synchronous errors, this tapping holder is said to reduce thrust load by as much as 90 percent.

Share

Most CNC machine tools now offer rigid tapping capability as a standard feature. During rigid tapping cycles, the machine’s spindle rotation and feed are synchronized to match a specific thread pitch as the tap is quickly driven in and out of a hole.

Some amount of synchronization error is inevitable with rigid tapping, although it is generally not problematic with new machines. Yet as a machine ages and its components wear, the discrepancy between the tap’s pitch and the spindle speed and feed can become more pronounced. The resulting higher thrust loads on the tap greatly shorten its effective life. Plus, the reversing tap tends to recut and damage the freshly machined threads as it exits the hole.

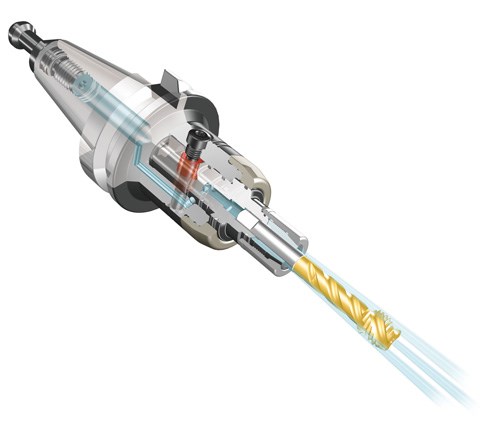

By allowing just a slight amount of axial movement to compensate for synchronous errors, Big Kaiser’s Mega Synchro tapping holder can reduce thrust load by as much as 90 percent, according to the company. The error compensation (and reduction in thrust loads) is facilitated via a mechanism that absorbs the pitch difference between the tap and synchronous machine movement. Located at the top of the tapping holder is a small, flexible bushing through which a screw attaches the tapping holder to the tool body. The bushing provides the tiny amount of flex that allows the tap to accurately follow the threaded path out of the hole, minimizing thread recutting.

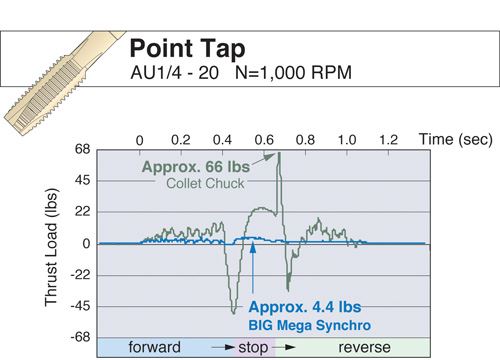

The chart to the right offers an example of measured thrust loads for a ¼-20 point tap running at 1,000 rpm used to thread aluminum. When held in a typical collet chuck, the tap experiences approximately 50 pounds of negative thrust load as it comes to a stop and 66 pounds of positive thrust load when it reverses. Maximum thrust load using the Mega Synchro tap holder is just 4.4 pounds.

The Mega Synchro is capable of supplying coolant to the periphery of the tap as well as through the tap. (Maximum internal coolant pressure is 1,000 psi.) This benefits tap life by reducing friction and helping with chip evacuation. The internal coolant passages route coolant around the error-compensating bushing to isolate it from the axial pressure of the coolant. That means there is no load on the bushing due to coolant pressure.

The tapping holder accommodates tap sizes ranging from No. 2 to ¾-inch. It is available in 45 versions, including slim models that allow access to confined areas. It is also offered in 41 body models, including Big-Plus, HSK, Capto, Weldon and KAB modular.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

.png;maxWidth=300;quality=90)