Cutting Data, Indexable Inserts Optimize Fine Boring

By using digital technology and optimized indexable inserts from Big Kaiser, Schmauser Müller Metalltechnik has increased its process reliability and efficiency in fine boring applications as well as improved tool life.

Share

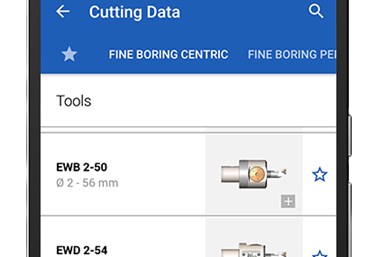

Big Kaiser’s digital app provides manufacturers with useful information that can save time and money. Photo Credit: Big Kaiser

Bavarian-based CNC manufacturing company Schmauser Müller Metalltechnik produces individual and small series of parts from a variety of materials with high precision and flexibility. Its service portfolio includes fixture construction, metal processing and associated CAD design. While the company serves automotive manufacturers, which are common in the areas, it tries to maintain a diverse customer base.

For example, the company is manufacturing an innovative feeding technology for a start-up company that uses physics and AI to simulate feeding processes with 100% accuracy, explains production manager Rainer Maurer. “Instead of a relying on a repetitive manual feeding process that frequently leads to unpredictable results, we've simulated the most complex conveyors, and can now manufacture a custom-fit solution precisely to the customer's requirements,” he says.

This approach has also been successful for SM Metalltechnik’s internal processes. By using digital technology and optimized indexable inserts from Big Kaiser, the company improved its manufacturing processes, gaining predictable results. “With Big Kaiser we have optimized our fine boring division on two levels simultaneously," Maurer says.

The Digital Twin

The digital twin is a virtual model of a real-world process, object or system, Maurer says. “It ensures that the user can be sure of success even before the actual process begins. Digital twins are particularly useful for one-off parts, since there is no previous data available, and the part must be made right the first time.”

SM Metalltechnik uses Autodesk’s HSM Works CAM software to create a digital twin for all relevant components. In this case, this is for the five-axis simultaneous milling machine C42 from Hermle with HS-Flex automation and for the clamping devices from SMW Autoblok. The tools themselves are digitally reproduced; in particular, the fine boring heads with adjustable projection lengths and diameters. Key details such as the Blum laser measuring system must also be considered to avoid any collision with the tool measuring system or other objects.

A digital twin is designed to offer the user the certainty of success even before the process begins. Photo Credit: Big Kaiser

After all the components are depicted, it is possible to simulate the best program sequence on the computer. This is particularly useful for complex five-axis simultaneous machining tasks where it is often impossible to continuously monitor each relative movement. A miscalculation in this area, like a collision, could prove fatal for the entire business process.

“A truly professional process must run reliably the first time, every time,” Maurer says. With digital twins, he says they can run their parts through the simulation and have full confidence in the final results — a process that complements the company’s modern machinery. “Luckily, our Hermle machine was digital twin ready, although we sometimes failed because we lacked precise complexity parameter data,” he says. “This led to unpredictable results, since each extension combination has a different digital twin. To overcome this, Big Kaiser provided us with the required data for all the relevant lengths and diameter combinations."

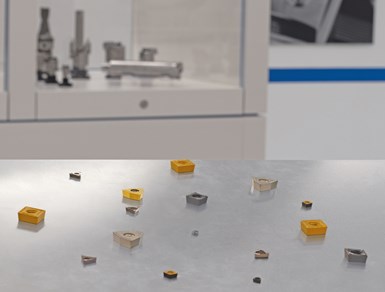

Choosing an indexable insert

Digitalization was not the only factor that contributed to SM Metalltechnik’s growing success in the fine boring process. Alexander Hartl, an application engineer at Big Kaiser, also contributed to this improvement by suggesting specific indexable inserts to make the process easier and more efficient.

“I analyzed SM Metalltechnik's requirements with Rainer Maurer in great detail,” Hartl says. “Based on the information, I was able to reduce the number of indexable inserts to 11 and still cover all the material and diameter combinations.”

Inserts from Big Kaiser — the company invests hundreds of hours every year in the development and testing of new inserts with a focus on fine boring. Photo Credit: Big Kaiser

“Having used many different cutting materials in the past, we were not sure which one was best suited to a particular project,” Maurer recalls. “Our guesswork often resulted in inserts breaking and unsatisfactory results.” This has all changed. Today, the company has a total of just 11 inserts in the facility, each for a clearly defined task and purpose. “Our state-of-the-art, automated machining can run unhindered, dimensional accuracy is constant and surface quality is perfect. In short, this improvement in our processes has enabled us to exploit the full potential of our existing machines,” he says.

Big Kaiser app for optimizing cutting parameters

It is common for companies to rely on cutting data that someone has already generated, Maurer says. For example, in the past an apprentice would ask their boss what to enter, and that boss would give a figure off the top of their head. These handed-down values would then haunt the company for many years, he says. This approach can waste a lot of potential and have negative effects on machining speed, resulting quality and tool life. According to Maurer, this example no longer applies to SM Metalltechnik.

The company has overhauled this method by using optimum cutting values determined by Big Kaiser’s research and development department, which tests new inserts to prolong their service life. The tests are extensive due to the many influencing variables: every diameter, material, spindle type and projection length has an impact on the result. The Big Kaiser app makes the results of these tests available to the user, enabling them to fully concentrate on their core business.

“Our fine boring process, in conjunction with CAM programming, now runs as follows: We enter the desired parameters, such as bore diameter, material and projection length, in the app. The app then tells us which Big Kaiser tool to fit with which insert, which extensions we need and what cutting data to set,” Maurer says. “Then we select the corresponding digital tool twin on the CAM workstation and program in the cutting values. That’s it. The operator no longer has to experiment with different values, but can rely on the results generated in the app, which simplifies the process enormously.”

According to Maurer, tool life is three times longer than it was previously, and the company replaces inserts after a pre-defined period of use instead of waiting until they not longer fit or something goes wrong.

How does the concept work?

Every year, Big Kaiser invests hundreds of hours in the development and testing of new inserts, with a particular focus on in-house optimization of the company’s fine boring heads. Big Kaiser has already patented important details such as a specialized chip groove to optimize chip removal and thus the surface quality of the finished bore.

The Big Kaiser concept focuses on universal fine boring inserts rather than specialized inserts for a specific application. According to the cutting tool manufacturer, specialized inserts work well for their intended purpose, but performance can deteriorate if the given conditions are altered. Also, specialization can lead companies that produce small series or runs of individual parts to use hundreds of indexable inserts to achieve the best possible results. The requires the user to have all tools on hand and use them at the right time with the right cutting data.

By optimizing daily machining processes, Rainer Maurer, Alexander Hartl and Dennis Heil have increased efficiency at SM Metallbau. Photo Credit: Big Kaiser

The Big Kaiser concept aims to avoid such scenarios. Instead, the company has created a universal insert designed to deliver reliability, efficiency and high precision in real-world manufacturing environments. The potential for such optimization is large, whether with the help of digital technology or with suitable inserts. At SM Metalltechnik, these new fine boring processes have proven successful.

Related Content

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreRead Next

Workholding Considerations for Five-Axis Machining

Five-axis workholding isn’t just about applying technology; it’s also about applying a different mindset.

Read MoreA Job Shop Approach to Automation

Through patient research and smart investing, this job shop has slowly grown its capabilities and is moving toward lights-out manufacturing for prototype work.

Read MoreStandardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

Read More