The old adage about a chain being only as strong as its weakest link recently proved more than just figurative for precision boring operations at N.C. Engineering (N.C.E.). When bores on critical parts started trending out-of-tolerance, the Gardena, California machine shop determined that its tooling wasn’t rigid enough to stay true with the spindle. Strengthening that critical link would require swapping the previous tooling for more stable Kaiser series 310 EWN finish-boring heads from Big Kaiser Precision Tooling (Hoffman Estates, Illinois). The resulting accuracy and surface finish improvements have enabled the shop to realize the productivity gains it expected from a new machine tool that had initially seemed like a disappointing investment.

N.C.E. is a family-owned machine shop that specializes in vertical and horizontal milling of most alloys and plastics. Founded in 1974 with a few Bridgeport machines and a single chucker lathe, the company expanded to tape-reading NC machines and eventually to modern, CAM-programmed CNC equipment. Complemented by a high-precision CMM, these machines are housed in an 8,000-square-foot facility where 16 employees work on jobs ranging from prototypes to long production runs. Most work is machined from barstock, plates, castings or forgings and ranges in size from small medical components to aerospace parts measuring as large as 40 by 80 inches. Common workpiece materials include aluminum, copper, brass and stainless steel, as well as some titanium.

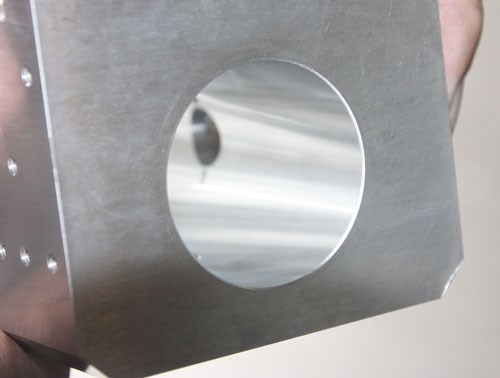

Although the shop takes on a diverse range of work, owner Gerald Fazis is quick to cite castings when asked for a specialty. In particular, he singles out N.C.E.’s ability to meet stringent requirements for flatness, perpendicularity and diameter. The shop’s reputation for such parts is one reason why management was particularly frustrated by a new machine that initially proved unable to maintain repeatability on tighter-tolerance bores, the most demanding of which can require holding location and diameter within ±0.0001 inch (±0.0025 mm). Scrap is not an option for castings, Mr. Fazis explains, and one oversized bore on a $150 to $200 casting is enough to lose not only the part and the money, but also the customer’s confidence. For one particularly problematic job, the shop had been scrapping two to three parts for every 10 it produced on the new machine.

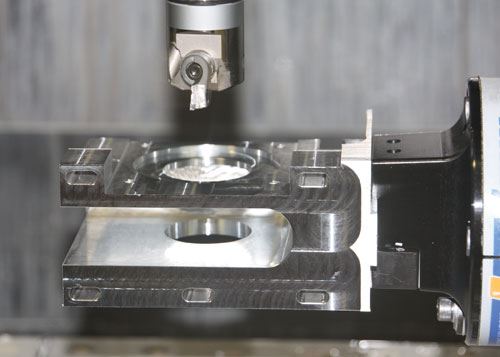

As it turned out, however, the machine itself was not at fault for the out-of-tolerance bores. Rather, the problem was the tooling. Mr. Fazis explains that this particular machine is N.C.E.’s first-ever 50-taper model. In prior years, the shop had used mostly 40-taper machines that didn’t apply the same amount of force during the tool-change cycle. “The tool-change arm engages and slams the toolholder around pretty hard—so hard it would move the boring bar by a thousandth of an inch or more and throw off the diameter set on the boring head,” he says.

The shop tried to use different boring heads, both from the same manufacturer and other suppliers, and even tried to slow down the tool-change process, all to no avail. Reaming the holes was not an option because many components machined at N.C.E. require true position tolerance. Achieving true position necessitates creating a new hole via a boring operation rather than following an existing hole with a reaming tool, Mr. Fazis explains. In the end, the shop had no choice but to relegate the new 50-taper machine—which represented an investment of several hundred thousand dollars—to roughing work and other operations that don’t require tight tolerances.

That was the norm for more than a year before consultation with a fellow machine shop owner led Mr. Fazis to consider the Kaiser series 310 EWN finish-boring head from Big Kaiser. An initial test run of that tool on a BT50 shank showed sufficient accuracy improvement to convince him to implement it on all of the shop’s CNC machines. “Because the Kaiser heads are so rigid and have such solid construction, they can take a little ‘whack’ without getting thrown off diameter,” he notes. “Overall, they are much more reliable, and once they are set, they don’t require any adjusting. This means we spend less time monitoring critical diameters.”

According to the supplier, many of the benefits of the EWN system can be attributed to a simple but precise adjusting mechanism that is designed for harsh manufacturing environments. This mechanism consists of a scale screw and nut that are precision ground and mated permanently together, so they must be changed together as a single component rather than separately. The fine surface finish of the ground threads minimizes wear and ensures the components move smoothly and accurately against each other during adjustments. Additionally, a flat detent in the locking screw presses against the cartridge without transmitting torque to ensure that locking the cartridge doesn’t affect diameter. According to the supplier, this design ensures accuracy and rigidity by eliminating backlash and ensuring the cutting edge doesn’t move when the unit is clamped. In contrast, other boring heads use different clamping systems that omit the lock screw entirely.

“Other precision boring heads on our 50-taper CNC weren’t stable enough to withstand the force of the tool change on the toolholder, but the Kaiser EWN line could,” Mr. Fazis concludes. “Now that we are able to use the machine properly, it’s one of our most dependable CNCs.”

.jpg;maxWidth=300;quality=90)