Setting Up and Operating Fine Boring Heads Just Got a Lot Easier

Sponsored ContentThe combination of a digital boring head integrated with tool data software dramatically reduces the time required to set up a fine boring head. And still more IIOT-enabled advancements are just around the corner that will finally automate many boring operations.

Share

Dialing in fine boring heads with just a Vernier dial screw can be tricky. When you’re trying to hold a bore to a few tenth’s, it can often take multiple test cuts before getting the ID tolerance just right. Digital technology is already making that setup process much easier on boring heads with digital readout displays. These tools tell you exactly what the setting is so that adjustment to a bore diameter can become a one-step process. Couple that with a software app that can read a head’s current setting and automatically calculate bore adjustments for you, and the process of setting up a fine boring head just got a whole lot easier and faster.

That’s what BIG KAISER can already do with its EWE series boring heads paired with its Boring Tool app. With a Bluetooth connection between the boring head and the app, the software already “knows” the current setting of the head and the nominal ID target, and then automatically calculates the exact adjustment necessary to meet the tolerance. It even suggests the correct feeds and speeds for the specific boring head and material.

But that’s just the beginning of where this technology is headed. In the near future digital boring technology will close the loop to provide highly automated boring solutions. Here’s what it can do now, and what’s coming in the near future.

See how an EWE boring head is set up using the BIG KAISER Boring Tool app.

How Digital Technology Makes Boring Head Setup Faster

Looking a little closer and the setup process for EWE boring heads explains what digital technology can do already. It starts with the app that can store data on a shop’s entire boring head inventory. Now the operator can begin by picking the specific tool to be used from a graphical menu. When cutting parameters are entered, such as bore diameter and material, the correct insert holder is automatically selected. The app then recommends an insert, calculates feeds and speeds and provides other useful process information.

The steps to setting up an EWE boring head.

With the boring head set and the cutting parameters entered into the CNC, the tool is now ready to be loaded into the machining center for a test cut. The bore is then measured, and the value entered into the app. The app then automatically calculates the proper final bore diameter setting. The operator then adjusts the head to that exact numeric value with confirmation on the boring head’s digital display. That’s it. Now the boring tool is ready to go.

Furthermore, the boring head can store historical data about the boring tool to aid in future setups and troubleshoot current jobs. “It helps to be able to look back at a job, not just to know what you did right, but also what you did wrong,” says Nick Jew, Research and Development Engineer for BIG KAISER. By eliminating past mistakes, it makes the operation safer and more effective.

A more detailed look at the tooling data stored in the BIG KAISER Boring Tool app.

What’s Next in Digital Boring Technology?

Using this digital approach substantially reduces setup time and increases precision in a way that is difficult to achieve with a purely mechanical process. Even more exciting is what’s in store for the next generation of this technology, already in development.

The ability to make in-process adjustments unlocks the door to machining multiple bore sizes with a single tool.

Currently, BIG KAISER is developing a fully automated fine-boring system. In doing so, the company hopes to eliminate the need to interrupt the process for manual adjustments, reduce the chance of human error, and enable unattended machining. Of course, these are the benefits of automating any machining process. The real draw to fine-bore automation is the development of the ability to automatically compensate for cutting insert wear. “All cutting inserts wear out over time,” Jew says. “But automated bores will not need manual intervention to compensate.” Instead, they will use touch probes to track the wear on the cutting insert, then automatically adjust the cut to make up for the loss of edge.” This can significantly reduce the rework time for a given part.

With the ability to automatically adjust boring diameter it will become possible to machine multiple bore sizes with a single tool. No more need for multiple tools set at different diameters, which will reduce overall tooling costs as well as save space in tool magazines.

Integrated vibration analysis will reveal correctable problems in the boring process.

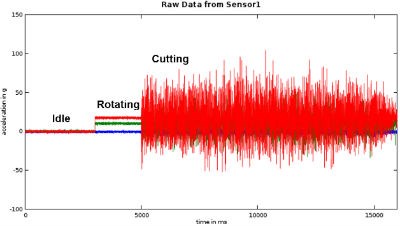

A connected boring tool will also be able to provide realtime process feedback with things like vibration sensors, already being used in some boring bars and other tools. Being able to record the vibration of the tool allows for many different analyses of the machining process. Before cutting, the tool can be rotated at programed RPM to check for unbalanced conditions or resonant frequencies to determine if rotation speed is within range of the tool, or if a damping system is needed for the tool projection length. During cutting other conditions can be checked such as issues with workholding, worn or damaged cutting edges, and to record overall cutting quality to fine-tune cutting conditions of the operation.

This picture of the future of digital boring technology is not just theoretical. It’s in test now, and BIG KAISER expects to have these capabilities available within the next year or so. Even just with the benefits of current technology, it’s a good idea to get started with digital boring technology today.

Go here for more information on BIG KAISER fine boring heads and the Boring Tool App.

.png)

.jpg)

.png;maxWidth=970;quality=90)