Kurt Manufacturing Company

Kurt Workholding

9445 E River Rd. NW

Minneapolis, MN 55433-5510 US

877-226-7823 | 763-574-8309

workholding@kurt.com

kurtworkholding.com

IS THIS YOUR COMPANY?

As Seen On Modern Machine Shop

Kurt Manufacturing Company Supplies the Following Products

- Angle & Sub Plates

- Assembly & Testing Automation

- Chucks, Special

- Clamps & Fixturing Devices

- Fixturing Systems

- Material Removal Automation

- Pedestal Type Fixtures & Tombstone Blocks

- Probes, Electromechanical

- Robots, Industrial

- Vises & Vise Jaws

- Workholding, Custom

Trade Names Offered by Kurt Manufacturing Company

- InnerLock

- MoveLock

- ClusterTower

- Versatile Lock

- CarvLock

- ToolBlox

- SideWinder

- DockLock

- ANGLOCK VISES

- SeraLock

- Groove Lock

- PINLOCK

- KurtSmart

- Hd & HDL Anglock Vises

- DoveLock

- MAXLOCK

- MiniLock

- DoubleLock

Editorial, News, and Products

-

Kurt Workholding Introduces Vise Models, Pallets, Jaw Options

IMTS 2024: Kurt Workholding expands its five-axis workholding lineup with three vise models and numerous pallets, as well as snap-on, snap-off jaw options for its vises.

-

Q&A: How a Self-Taught Machinist Started His Own Business

This machinist found an opportunity in a niche market and decided to learn machining and create his own business. Here's how he did it.

-

Kurt Workholding Vises Provide All-Directional Alignment

The DXH Hydraulic vise lineup features the proprietary Kurt AngLock spherical segment to reduce jaw lift and improve performance.

-

Kurt Manufacturing Acquires Bellatex Industries

Bellatex Industries is the owner of the Carvesmart dovetailed quick-change vise jaw system. Kurt has acquired the associated patents and inventory.

-

Kurt Workholding Adds New Compact Robotic-Arm Gripper

The RV24 Robotic Gripper’s design enables automated finger/end effector changes without changing the gripper body itself.

-

New Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of Modern Machine Shop, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

-

The Job Shop Is the First Half of the Business

By day, NTL Industries went from a lathe and a mill in a home garage to an 11-employee enterprise in under five years. By night, it tackles a new future.

-

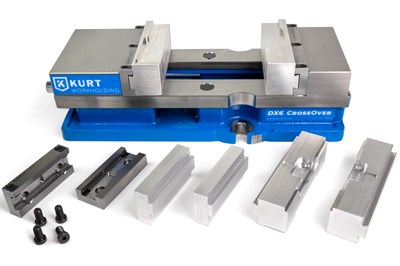

Kurt Manufacturing Introduces Compact Vise

The 8" DX8 CrossOver vise features a redesigned nut with less weight, a new brush seal design and a larger, stronger bearing pack for more durability.

-

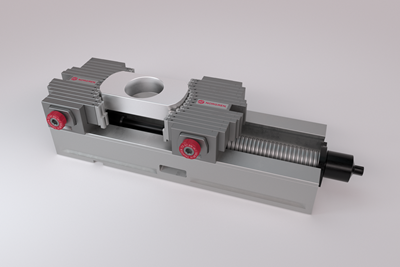

Norgren Introduces One-Size-Fits-All Soft Jaw

Norgren’s Adaptix Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the CNC machining process.

-

Absolute Machine Tools Offers New Automation Package

Absolute Machine Tools and Kurt Workholding have partnered to offer an automation package designed to make automation simple.

-

Choosing Workholding to Meet Machining Challenges

When it comes to workholding, shops can choose from options that can provide flexibility, help increase throughput and enable five-axis machining.

-

Standardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

-

Kurt's Pyramid Workholding Platform Available in Vise Kits

Kurt offers a pre-engineered set of kits for its Pyramid workholding platform accommodating 12 different vise models.

-

Kurt's VersatileLock Vises Serve as Lighter Tombstone Alternative

Kurt’s VersatileLock can be mounted back to back to operate as a tombstone on smaller horizontal machining centers with work envelope and weight limitations.

-

Kurt Motorized Air Vises Improve Clamping Repeatability

Kurt motorized air vises are built to provide consistent preset clamping force and programmability of the vise opening.

-

Kurt's Pyramid Workholding Platform Ideal for Nesting Five-Axis Vises

The Kurt Pyramid workholding platform is designed to attach three Kurt vises for five-axis machining multiple parts in one load.

-

Kurt's Rotary Table Workholding System Provides Three-Sided Workpiece Access

Kurt’s rotary table workholding system is designed using the company’s DX6 CrossOver hydraulic vise with a trunnion mounted onto a fourth-axis rotary table.

-

Shop Works to get the Most Out of Its Five-Axis Capabilities

Vertical machining centers with rotary tables helped this Indiana job shop set itself apart, but specific machine features and additional equipment have helped it use them more efficiently to grow its business.

-

Clamping System's Lock-Down Force Prevents Vibration

Kurt Manufacturing Co.’s pneumatic Zero-Point clamping system runs on existing shop air supply.

-

Reusable Master Jaws Reduce Setup Time

Kurt’s DoveLock master jaws are designed to be installed in replacement of standard cap screw jaws for quick-change capabilities.

-

Motorized Air Vises Designed for Automated Machining Cells

Kurt’s line of motorized air vises utilizes air-powered motors to provide consistent preset clamping force and programmable vise opening.

-

Reduced-Size Vise Provides Strong Clamping

Kurt has released the DX4 CrossOver Vise, a reduced size version of its DX6 CrossOver Vise.

-

Hydraulic Workholding Enables Choice of Preferred Clamping Method

Kurt Workholding’s KHU6 hydraulic unit has both single- and double-acting capabilities, enabling the user to choose a preferred clamping method.

-

Modular Towers Enable Mixing, Matching of Clamping Components

Kurt’s SeraLock Towers, along with its WedgeLock and MoveLock workholding modules, provide density, accuracy and flexibility to accommodate different part sizes and multiple parts.

-

The Value of Double-Checking Your Programs

Using simulation software to validate CNC programs for large, expensive precision parts helped one manufacturer reach a delicate balance of speed and accuracy.

-

Simulation Software Helps Shop See, Prevent Costly Errors

Kurt Manufacturing needed to validate CNC programs for large, expensive precision parts. NCSimul Machine simulation software from Spring Technologies saved setup time, reduced machining errors and produced accurate parts quickly.

-

Small, Screw-Down Clamp for Various Tables, Fixtures

The Kurt MiniLock is a small, low-profile screw-down clamp designed as a cost-effective, easy-to-use option for rigidly clamping components on machine tables, fixture plates, tombstones and trunnion fixtures.

-

Vises Designed for Precision CNC Production to Toolroom Applications

Westec 2017: Kurt will show its lineup of vises for five-axis, high-precision production machining, including its DX6 CrossOver vise.

-

Hydraulic Workholding Towers Offer as Many as 12 Clamping Stations

Kurt Workholding offers a complete line of high-density CarvLock workholding towers for precision machining with eight or 12 clamping stations in both manual and hydraulic models.

-

Self-Centering Vises Resist Jaw Deflection, Part Lift

Kurt’s MaxLock HP series of self-centering vises are designed for maximum five-axis workholding rigidity.

-

Dovetail Vises Provide Five-Sided Access to Workpiece

Kurt’s new DoveLock dovetail vises are designed for high clamping strength and five-sided access to the workpiece in five-axis, four-axis and palletized CNC machining systems.

-

New Workholding Setup Enable Lights-Out Production

For Idex Health and Science, manufacturing glass components was time-consuming on a VMC. Switching to an HMC with a Cluster Tower vise with DoveLock jaws from Kurt Manufacturing enabled more stable, lights-out machining.

-

Vise Achieves Flatness, Parallelism Requirements

Kurt’s DX6 CrossOver vise is designed to achieve high workholding strength and performance where flatness and parallelism are critical.

-

Vise Reduces Setup Time for Secondary Operations

The Kurt SideWinder vise provides vertical workholding without interfering with an existing host vise or the spindle.

-

New Jaws Speed Change-Over for Short-Run Jobs

This shop found that a quick-change jaw system reduced 80-minute change-over times to just 8 minutes.

-

Vise within a Vise System Enables Economical Five-Axis Machining

A unique vise-within-a-vise system using Kurt workholding enables Peterson Machining Inc. to cost effectively use five-axis manufacturing for complex parts.

-

Pencil Probe Provides LDVT Measurement with High Accuracy

The KurtSmart Probe from the Kurt Industrial Products Division combines the advantages of a linear variable differential transducer (LDVT) with the accuracy of a linear scale in a more affordable package, according to the company.

-

Pull-Type Vise Minimizes Jaw Deflection

Kurt Workholding’s HD690 pull-type vise features a 9" jaw opening for clamping larger workpieces with minimal stationary jaw deflection.

-

Hydraulic Clamping Systems for High-Production Machining

Kurt’s hydraulic clamping systems are designed for faster, more accurate workpiece clamping.

-

Vise Line Reduces Stress Under Load

Kurt’s pull-type HD690 vise line is available in standard and reverse jaw models, and in manual and hydraulic versions.

-

Workholding That Works for Jesel

The maker of racing engine components produces parts that have many permutations within each product line. Here is how Jesel sets up work for cost-effective, responsive machining.

-

Workholding System Reduces Setup Time

Kurt’s DockLock zero-point workholding system is designed for quick alignment and setup of parts on horizontal and vertical machining centers.

-

Flexible Fixturing Furnishes Faster Setups

Replacing dedicated fixtures with a system incorporating custom jaws from Kurt Manufacturing has reduced setup time and freed capacity at this manufacturer of hydraulic snowplow equipment.

-

Hydraulic Pump for Vises, Cluster Towers, Swing Clamps

The 5,000-psi air hydraulic pump from Kurt Workholding is designed to provide constant hydraulic pressure for precision clamping applications.

-

2D and 3D Viewing and Downloads Available on Kurt Workholding's Website

Kurt Workholding has enhanced its website, kurtworkholding.com, so users can download 2D drawings and 3D modules of its precision vises.

-

Five-Axis Vise for Close-Tolerance Repeatability

Kurt's MaxLock vise is designed to hold parts with maximum rigidity for close-tolerance repeatability in all axes.

-

Targeted Five-Axis Machining

Focusing on a particular part size range allows this shop to use a versatile type of five-axis machine tool. Five-axis machining now makes up 40 percent of the shop’s business.

-

Workholding Tools Enable Faster Job Change-Overs

Kurt’s HD and HDL vises and towers are designed for faster setups, larger workholding capacity, and greater flexibility and precision to handle a variety of part configurations.

-

Automated Production on HMCs Requires Automated Gaging

An innovative approach to automated gaging helps deal with a fundamental challenge inherent to a flexible, multi-machine environment: Many machines with many operations multiply the chances for error.

-

Locating/Mounting System Eases Component Changes

Kurt’s PinLock system is designed to ease attachment and removal of fixtures, subplates and vises from machining centers.

-

Get That Part off the Table

Vertical machining centers with simultaneous five-axis machining capability have become popular in recent years.

-

Vise Rigidity Boosts Robot Cell Output

To automate the fixturing of round machining center components, Haas uses a custom, robot-tended setup incorporating MoveLock vises from Kurt manufacturing. Thanks to these vises’ rigidity, the machine tool builder has doubled the output of its robot cells compared to previous setups.

-

Small Part Precision Clamping

The Kurt MiniLock is a small, screw-down clamp that operates similarly to a precision vise.

-

Vise Automates Milling, Eliminates Fixture Setup

A machine tool builder phased in a three-machine robotic cell to improve productivity and automate machining of spindle shafts. A new vise model that provided repeatable clamping and eliminated fixture setups was key to the success of the new project.

-

The Right Fit Is In The Fixtures

Custom engineered workholding fixtures are key to the effectiveness of an unusual Automated Production System (APS) recently installed at Kurt Manufacturing. It helps that one of this company’s specialties is custom engineered workholding fixtures.

-

Fixtures Facilitate Transfer Line Automation

Replacing fixtures in an automated transfer line with robot-integrated models from Kurt Manufacturing helped this tier one automotive manufacturer eliminate issues with part distortion and expand production.

-

Automated Workholding Systems

The company offers an array of workholding and high-productivity products.

-

Compactor Streamlines Aluminum Chip Handling

Shops often view metal chips left over from machining operations as no more than a housekeeping headache. However, the experience of this precision manufacturer demonstrates that with the proper recycling equipment, viewing chips as an important part of the overall manufacturing process can improve a shop’s bottom line.

-

Clamping System Enhances Productivity Of Five-Axis Machine

With Kurt Manufacturing Company's VB 5X100 Schenke 5.1 clamping system, this shop managed to use a single five-axis VMC to cut a mold that previously required two separate machining centers.

-

Five-Axis Machining Has Special Workholding Needs

This clamping system allows a workpiece to be rigidly clamped while raised up from the surface of the worktable on a five-axis machining center. Moving the workpiece away from the table creates clearance for the spindle nose and cutting tool when the table swivels the workpiece for multi-sided machining, or when the spindle head rotates and swivels to do contouring or sculptured surfaces. Without this clearance, the user may be forced to refixture the part or to switch to a longer, less rigid tool.

-

Ductile-Iron Towers Provide Needed Clamping Rigidity

Holding 0.001-inch tolerances while machining and removing large amounts of material from a brass part is a challenging task when the job is run at 10,000 revolutions per minute with feed rate of 240 inches per minute.

-

Improving In-The-Cut Time And Part Setups With Ductile Iron Vises

Previously using double-station vises with aluminum bodies, Vincent Precision Machining's workholding upgrade to HDL vises from this manufacturer provided the workholding rigidity that assured repeatable precision part after part, while the setup eliminated expensive scrap parts.

-

Vises Used As An Alternative To Custom Fixturing

Impact Forge, Inc. (Columbus, Indiana) is comprised of four companies that offer a range of forging technologies, including producing hammer dies requiring large milling operations. The company reports that positioning and clamping these dies in a machining center can be challenging because of characteristics such as heaviness and bulkiness.

-

Vise Configuration Helps Company Achieve Tight Tolerances

This manufacturer is a global supplier of pressure regulators, valves and electronic controllers for a range of industrial and high-purity applications.

-

Combining Workholding Vises And Fixtures Maximizes Machine Output

This company is a manufacturer of automotive tools and equipment ranging from heavy-duty diesel engine service tools to wheel dollies and bearing cup removers. Many of the components for these products require milling, drilling and tapping on machining centers.

-

Workholding System Uses Stepped Jaws To

The Integrated Hydraulics division of Parker Hannifin Corporation is a manufacturer of hydraulic cartridge products and integrated systems used in fluid power applications.

-

Securing A New Process

A Minnesota manufacturer of precision parts boosts productivity by expanding its workholding capacity.

-

Workholding Provides Maximum Versatility For Unattended Machining

This company manufactures a broad line of custom manifold assemblies used in all types of fluid power applications such as off-highway vehicles, tractors and road graders. These manifolds are made from 6061 aluminum and are finish machined in a wide range of sizes and with numerous SAE ports, valve cavities and threaded holes, some with precision features designed to handle various fluid power components.

-

Flexible Workholding Maximizes Machine Output

More and more companies are finding that by juggling work scheduling on their machining centers and adding a vise tower setup on the right machine, they can increase productivity without adding operating hours.

-

Interlocking Serrated Surfaces Enhance Modular Fixturing

This pedestal-type workholding fixture matches its grooves and ridges naturally and automatically aligns the surfaces of the workpiece, making subsequent reclampings highly repeatable.

-

Flexibility Is A Vise

The ubiquitous table vise is more than a fixture in metalworking shops. It's a necessity. Like the machine tools they attach to, metalworking vises have had their share of technical advances aimed at extending the flexibility of these popular workholders.

-

More Parts, Less Space

High-density workholding techniques allow this shop to achieve high production-like efficiencies on an inexpensive CNC bed mill.

.jpg;maxWidth=300;quality=90)